Retsch SK 100 User Manual

Page 16

05/04/2012

Retsch GmbH

16

0002

Reset impact gap

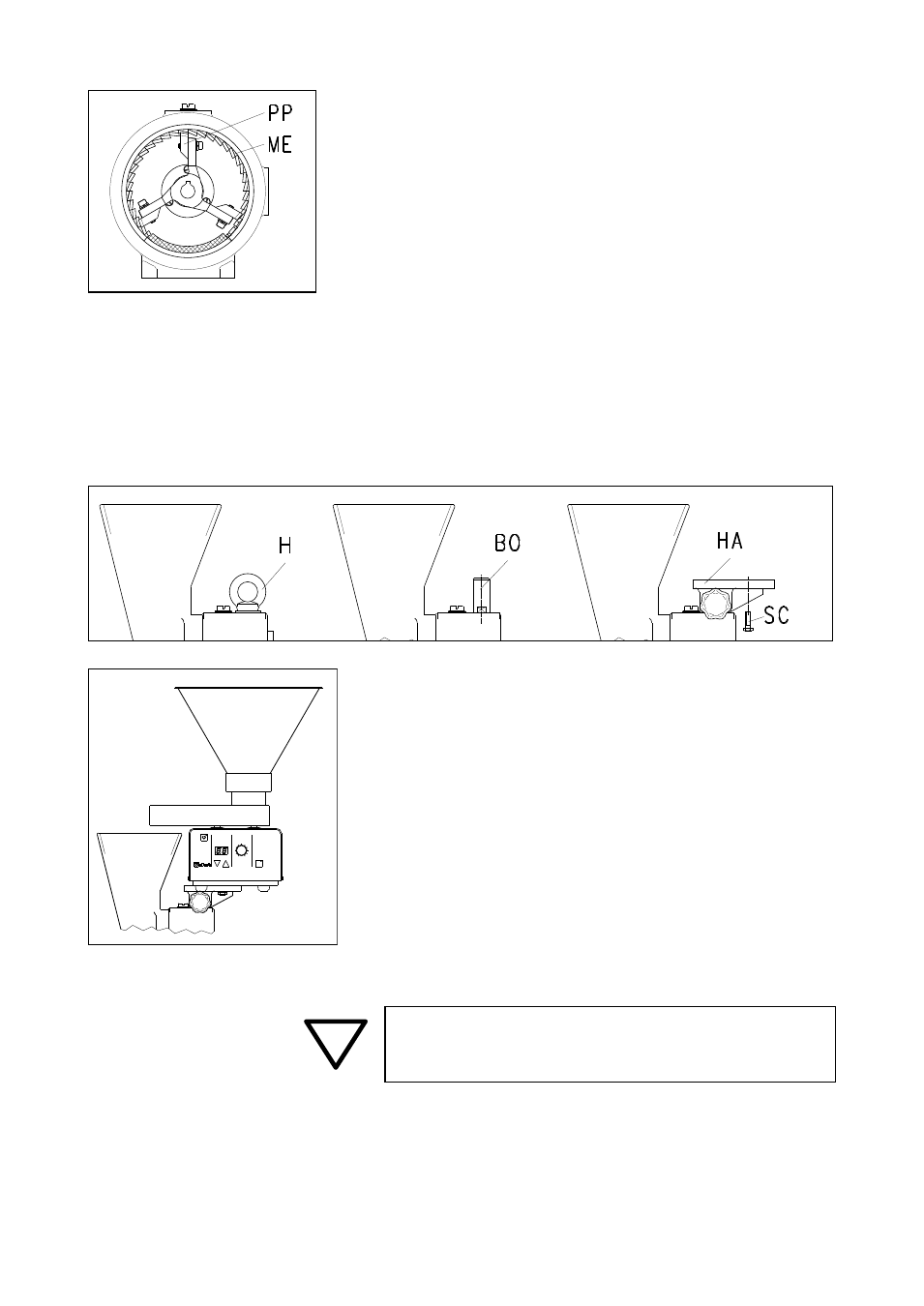

Fig.10

From time to time the gap between the grinding insert and the impact

plates of the cross beater should be checked.

Fig. 10

* Pull out mains plug

* Open mill housing

* Check gap between the grinding insert ME and the impact plate PP

using a leaf gauge = required ~1 mm, the gap leading to the bot-

tom sieve should not be <1 mm.

* If necessary reset impact plates using SW5

socket spanner

Mounting a vibratory feeder

When feeding larger quantities, it is advisable in general to feed the

material to be crushed evenly using a feed device. This largely pre-

vents any unnecessary load on the grinding tools and reduces pos-

sible friction heat. A suitable means of providing an even material

feed is the DR 100/75 vibratory feeder available as accessories.

Fig. 14

Fig.11

Fig.12

Fig.13

Fig.14

Prepare the DR 100/75 for feed operation in accordance with

your operating instructions.

Mounting :

* Screw out ring bolt H,

Fig.11

* Screw in bolts BO,

Fig.12

* Push on fixture HA with T screw,

Fig.13

* Tighten T screw

* Mount and align DR 100/75

* Fasten with the two hexagon screws SC

M6x20 DIN933,

Fig.13

* Plug power connection cable of the DR 100/75 in a socket

outlet with earthing contact

* You will find the voltage and frequency of the DR100/75 in-

dicated on the nameplate

If the values on the nameplate are not adhered to, electronic and me-

chanical components may be damaged.