Assembly – MacDon 2000B Pick-Up Reel User Manual

Page 12

11

ASSEMBLY

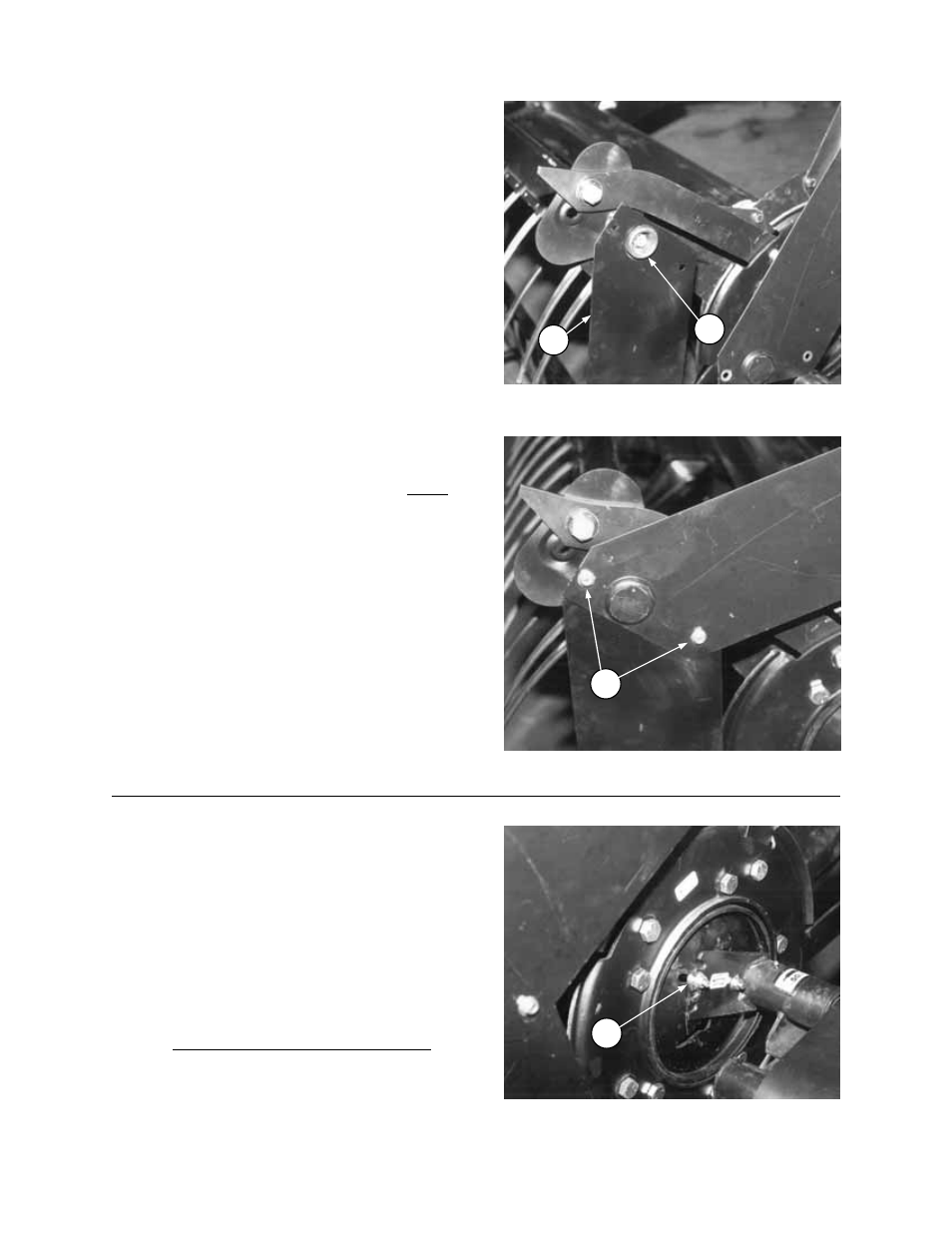

12. INSTALL END SHIELDS

a. Insert shield bearing (C) into pocket (with hole)

in end shield (D). The step on the bearing must

protrude through hole in end shield.

b. Attach bearing to crank (or end bat for 36') with

3/8 x 5/8 inch flange head self-tapping screw.

Tighten enough to prevent rotation of the shield

bearing against end of crank tube. Do not over-

tighten, plastic bearing may split.

c. Bring the closed end of the next end shield up,

enclosing the bearing. Fasten end shields with

5/16 x 3/8 Phillips truss head machine screws

and nuts (E).

IMPORTANT: To avoid damage to reel bats

and shields, screw heads must be to the inside

of the reel.

Leave hardware loose until all shields are

attached.

d. Clearance between end shields and header end

sheet (or nearest point of contact) should be 1

to 2 1/2 inches (25 - 64 mm).

If necessary, adjust reel support arm braces to

center the reel in the header. See your header

Operator's Manual.

13. ADJUST FINGER PITCH POSITION.

See "Recommended Settings" on page 14 and

choose a position best suited to your conditions.

IMPORTANT: To prevent twisting damage to

the reel, be sure reel support arms on header

are lifting in phase before installing bolt (A). If

installing reel on a new header, bleed reel lift

hydraulics before installing bolt (A).

Install 3/8 x 3/4 carriage bolt (A) and flange nut

in the same position at both ends of the reel.

IMPORTANT: Reel damage can result if reel is

unevenly adjusted.

INSTALL END SHIELD BEARINGS

C

D

ASSEMBLE END SHIELDS

E

ADJUST FINGER PITCH

A