Precision Turbo and Engine BigStuff3 GEN3 1st Gear Spark Retard with Traction Control System (SR2) User Manual

Page 13

Rev 1.0

13

Important Note:

To ensure that the 1

st

Gear Retard system becomes active when the trans-brake or clutch

are released (the point in time when the Timer Enable wire is supplied 12V), make sure the Minimum RPM

& TPS values are exceeded while on the MSD 2/3-Step when the trans-brake is on or the clutch is depressed.

Setting up the Timing Retard Traction Control System

The first step in setting up the Timing Retard Traction Control System is to configure Driveshaft Error Table.

The other necessary parameters were configured, while setting up the “1

st

Gear Retard” system.

Driveshaft Error Table Configuration

The difference between the “actual” and “desired” driveshaft speed is called “Driveshaft Error”. The GEN3

ECU uses a “Driveshaft Error” table to determine how much spark retard to apply for a given level of

driveshaft error. The driveshaft RPM error range in the table goes from zero (0) RPM error to 896 RPM

error. Each cell represents 128 RPM of driveshaft error. A linear interpolation is used by the GEN3 ECU

between rpm cells.

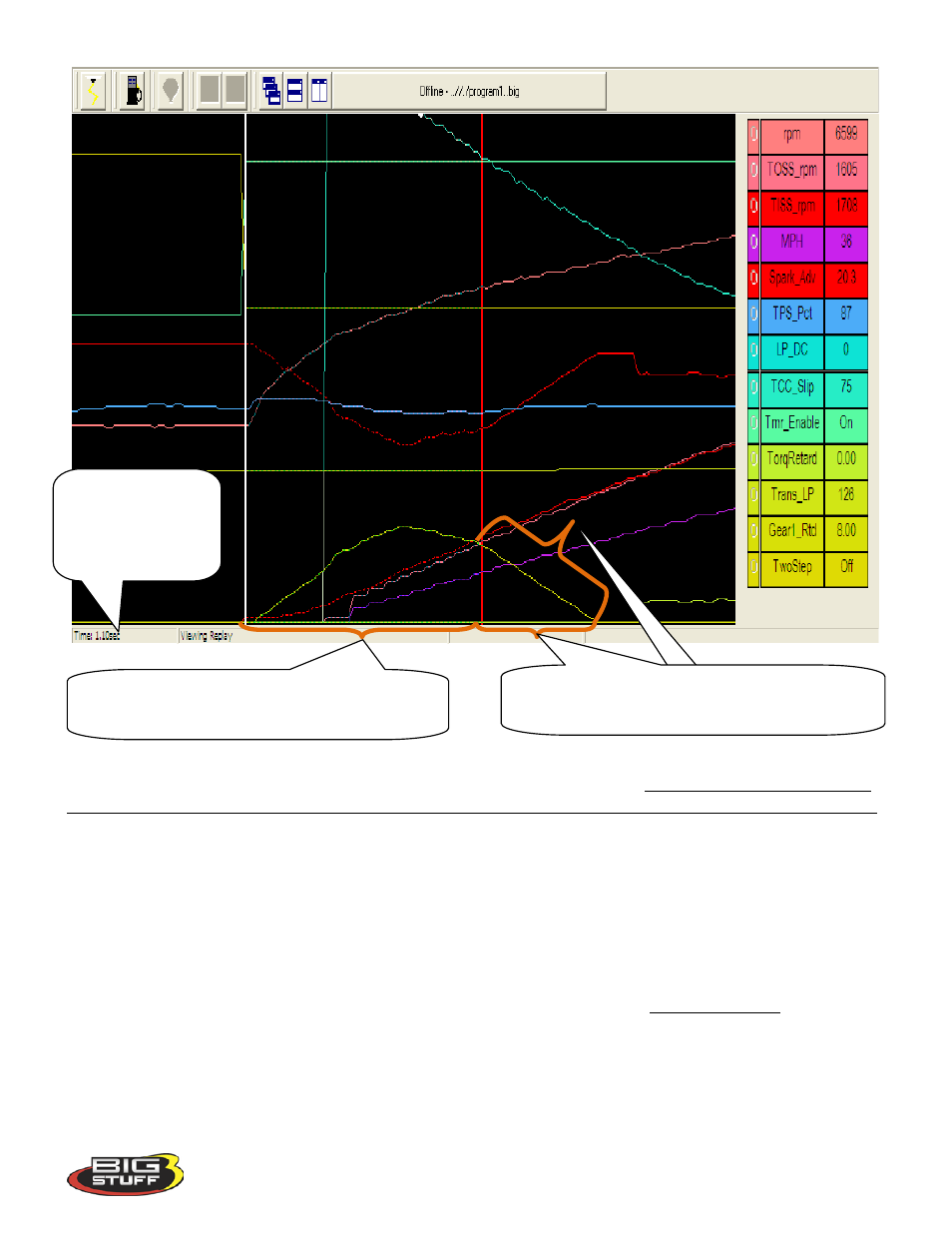

Shows 1

st

Gear Retard system is functional per time

period defined in calibration (1.1.seconds). After 1.1

seconds, the system enters the blend period

1

st

Gear Retard

Period from Timer

Enable “ON” point.

Hit “Z” to zero out

the cursor

Blend time period and the slope of the line are

defined by the number of “Counts” inputted into the

“Blend Rate” cell under Boost Parameters