Standard non-separating mechanical interface, Optional mechanical interfaces – Orbital Minotaur VI User Manual

Page 65

Minotaur IV • V • VI User’s Guide

Section 5.0 – Payload Interfaces

degree marks are counterclockwise when forward looking aft. The positive X-axis is forward along the

vehicle longitudinal centerline, the positive Z axis is along the 180 deg angular, and the positive Y axis is

along the 90 deg angular station, and completes the orthogonal system. The origin of the LV coordinate

system is centered at the Stage 1 nozzle exit plane of the LV and the vehicle centerline (X = 0.0 in., Y =

0.0 in., Z = 0.0 in.).

5.2.2. Orbital Supplied Mechanical Interface Control Drawing

Orbital will provide a toleranced Mechanical Interface Control Drawing (MICD) to the payload contractor to

allow accurate machining of the fastener holes. The Orbital provided MICD is the only approved

documentation for drilling the payload interface.

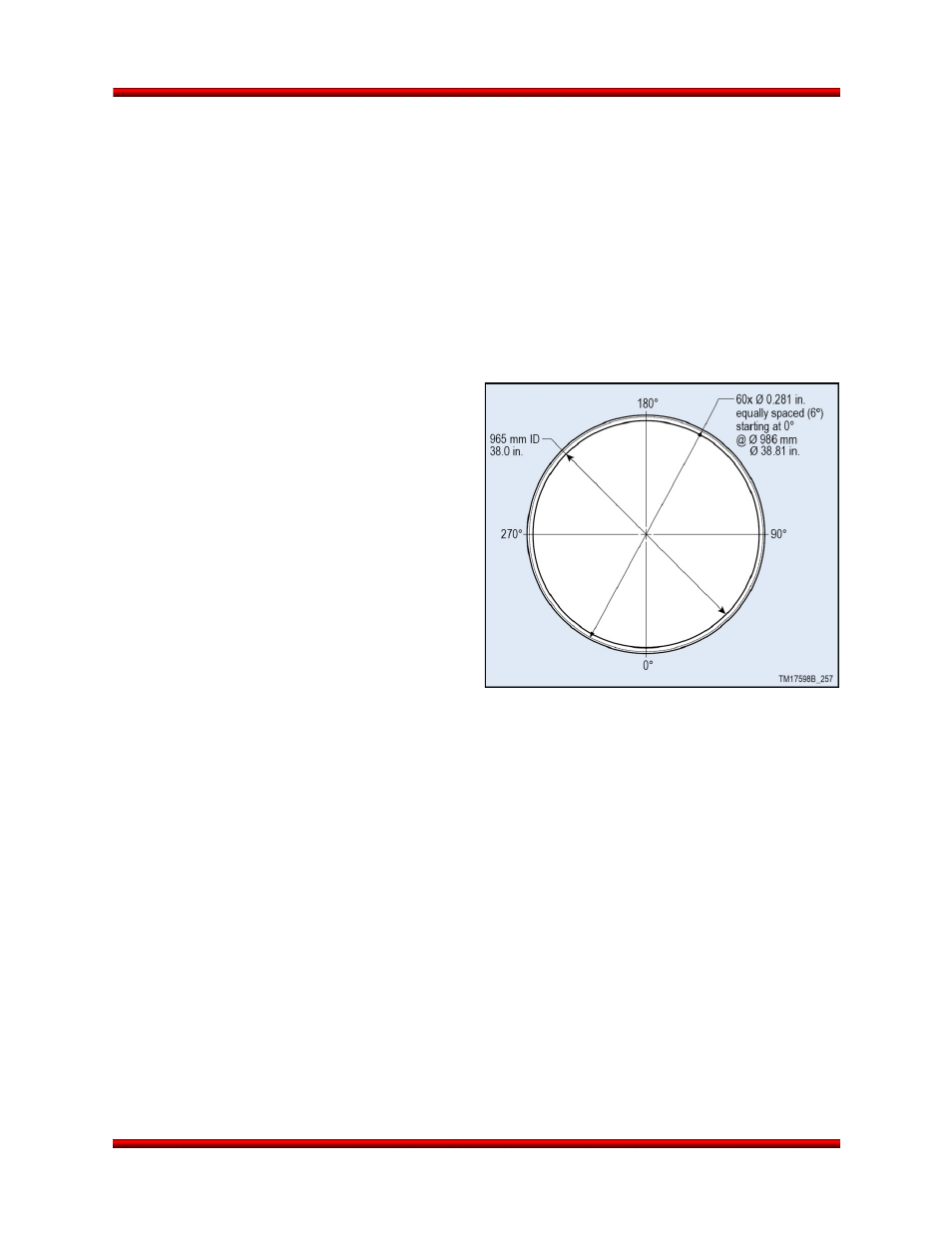

5.2.3. Standard Non-Separating Mechanical Interface

Orbital’s payload interface design provides a

standard interface that will accommodate multiple

payload configurations. The Minotaur IV baseline is

for payloads to provide their own separation

system or for payloads that will not separate. The

standard interface is a 986 mm (38.81 in.) diameter

bolted interface. A butt joint with 60 holes

(0.281 in. diameter) designed for ¼ in. fasteners is

the payload mounting surface as shown in Figure

5.2.3-1.

5.2.4. Optional Mechanical Interfaces

Alternate or multiple payload configurations can be

accommodated with the use of a variety of payload

adapter fittings as listed in Table 5.2.4-1. The

Minotaur IV family of Launch Vehicles allows

flexibility in mounting patterns and configurations

(Figure 5.2.4-1).

Figure 5.2.3-1. Standard, Non-separating 38.81”

Diameter Payload Mechanical Interface

Release 2.0

June 2013

50