Maintenance, Bearing lubrication, General transmission care – Multiquip SP2S20H User Manual

Page 38: Transmission reservoir cup, Servicing, Drive chain

page 38 — Sp2S20h paVeMeNT SaW • operaTioN MaNual — reV. #1 (02/17/12)

BeariNg luBriCaTioN

There are four grease points for the saw. Use only Premium

Extreme Pressure Grease, conforming to NLG1 Grade #2

consistency, to grease the zerk fittings.

1.

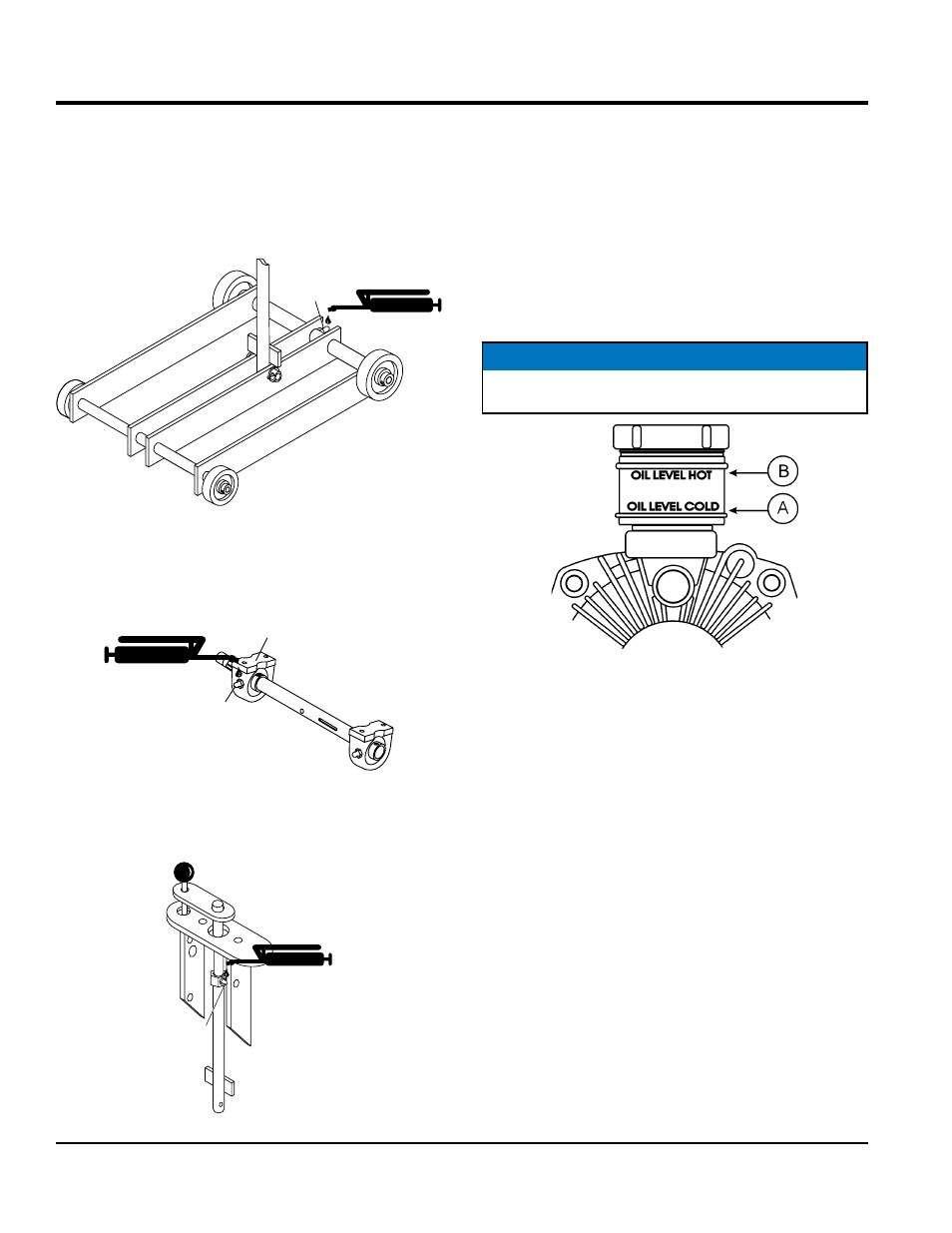

rear Wheels (1) — Grease daily (Figure 44).

Figure 44. Rear Wheels

2.

Blade Shaft Bearings (2) — Grease daily (Figure 45).

Figure 45. Blade Shaft Bearings

3.

raise/lower adjust Tube (1) — Grease daily (Figure

46).

Figure 46. Raise/Lower Adjust Tube

ZERK

GREASE

FITTING

ZERK

GREASE

FITTING

PILLOW

BLOCK

BEARING

ZERK

GREASE

FITTING

Maintenance

geNeral TraNSMiSSioN Care

The saw utilizes spline gear wheel design coupled with an

EATON Model 7 Hydrostatic Transmission that provides

forward/reverse propulsion. The simple design of the

system keeps maintenance to a minimum.

Transmission reservoir Cup

Check every 8 hours of operation. When the transmission

is cold (A), check oil level against the level indicator.

Figure 47. Transmission Reservoir

Servicing:

The transmission reservoir is factory-filled. Should

servicing be required, use SAE20W-20, API classification

(SE,CC,CD) or better, General Motors Dexron B, Ford

M2C-33F, M2C-41A or International Harvester Hy-Tran

fluids. For extreme hot weather, drain oil and refill with an

oil having a viscosity of SAE30W-30 or SAE40W-40.

Drive Chain:

Check every 50 hours. Periodically wipe the chain clean

and relubricate with penetrating chain oil.

The drive chain may stretch requiring tension adjustments.

To adjust the drive chain tension perform the following

steps. Refer to Figure 48 for location of parts.

1. Loosen the four transmission attachment screws.

2. Pivot the transmission in the “U” slots of the transmission

mount until the proper tension is achieved.

NOTICE

Do NoT use multiple viscosity oil. Do NoT overfill.