Maintenance – Multiquip SP2S20H User Manual

Page 35

Sp2S20h paVeMeNT SaW • operaTioN MaNual — reV. #1 (02/17/12) — page 35

Maintenance

General maintenance practices are crucial to the

performance and longevity of your saw. The extreme

environments of sawing operations require routine cleaning,

lubrication, belt tensioning, and inspection for wear and

damage.

The following procedures, devoted to maintenance, can

prevent serious saw damage or malfunctioning.

geNeral CleaNliNeSS

Clean the machine daily. Remove all dust and slurry buildup.

If the saw is steam-cleaned, ensure that lubrication is

accomplished

aFTer steam cleaning.

eNgiNe CheCK

Check daily for any oil and/or fuel leakage, thread nut and

bolt tightness, and overall cleanliness.

CauTioN

Before servicing or inspection,

alWayS park the saw

on a level surface with the blade removed. The Console

Engine ON/OFF switch and Engine ON/OFF switch

should be in the

oFF position.

WarNiNg

Some maintenance operations may

require the engine to be run. Ensure

that the maintenance area is well

ventilated. Exhaust contains poisonous

carbon monoxide gas that can cause

unconsciousness and may result in

DeaTh

CauTioN

ALWAYS allow the engine to cool

before servicing. NEVER attempt any

maintenance work on a hot engine.

CauTioN

alWayS make sure that the spindle has

CoMpleTely SToppeD roTaTiNg

before servicing blades and engine

components.

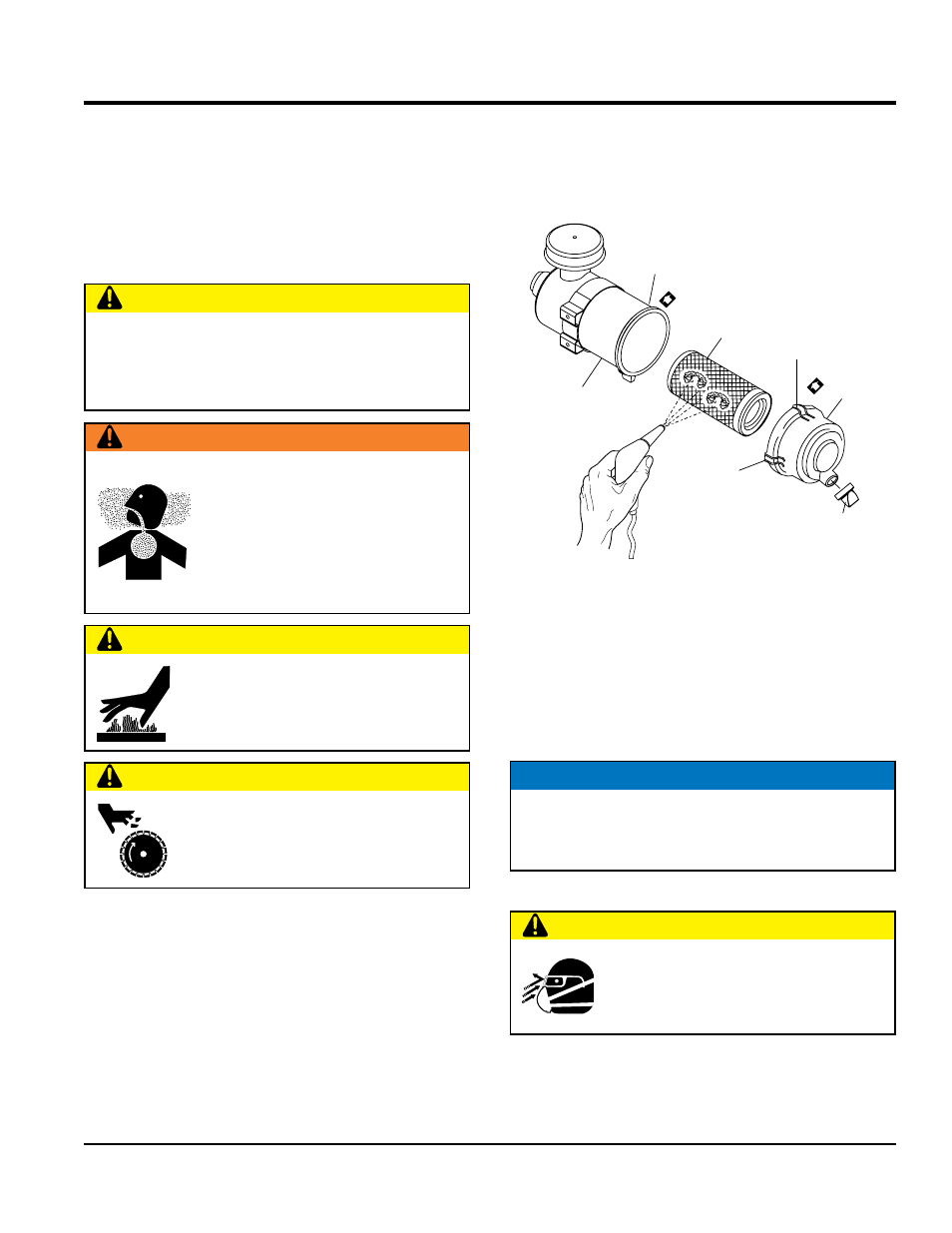

air CleaNer

This engine is equipped with a replaceable, high-density

paper air cleaner element. See Figure 37 for air cleaner

components.

Figure 37. Air Cleaner Components

1. Check the air cleaner daily or before starting the engine.

2. Check for and correct heavy buildup of dirt and debris

along with loose or damaged components.

3. Replace the element if it is found to be damaged,

excessively dirty, or oily.

Cleaning the air Cleaner

The air cleaner should be cleaned every 6 months. To

service the air cleaner perform the following steps. See

Figure 37 for location of parts.

LATCH

DUST

PAN

MAIN

ELEMENT

AIR CLEANER

CASE

ARROW

MARK

(CASE)

ARROW

MARK

(DUST PAN)

EVACUATOR

VALVE

NOTICE

Operating the engine with loose or damaged air cleaner

components could allow unfiltered air into the engine

causing premature wear and failure.

CauTioN

Wear protective equipment such as

approved safety glasses or face shields

and dust masks or respirators when

cleaning air filters with compressed air.