Inspection – Multiquip SP2S20H User Manual

Page 23

Sp2S20h paVeMeNT SaW • operaTioN MaNual — reV. #1 (02/17/12) — page 23

1. The transmission is factory filled with approved

hydraulic fluid that has a viscosity equivalent to SAE

20W-20. Should additional servicing be required, the

following hydraulic fluids are recommended:

• General Motors Dextron B

• Ford MM2C-33F

• Ford M2C-41A

• International harvester Hy-Tran Fluids

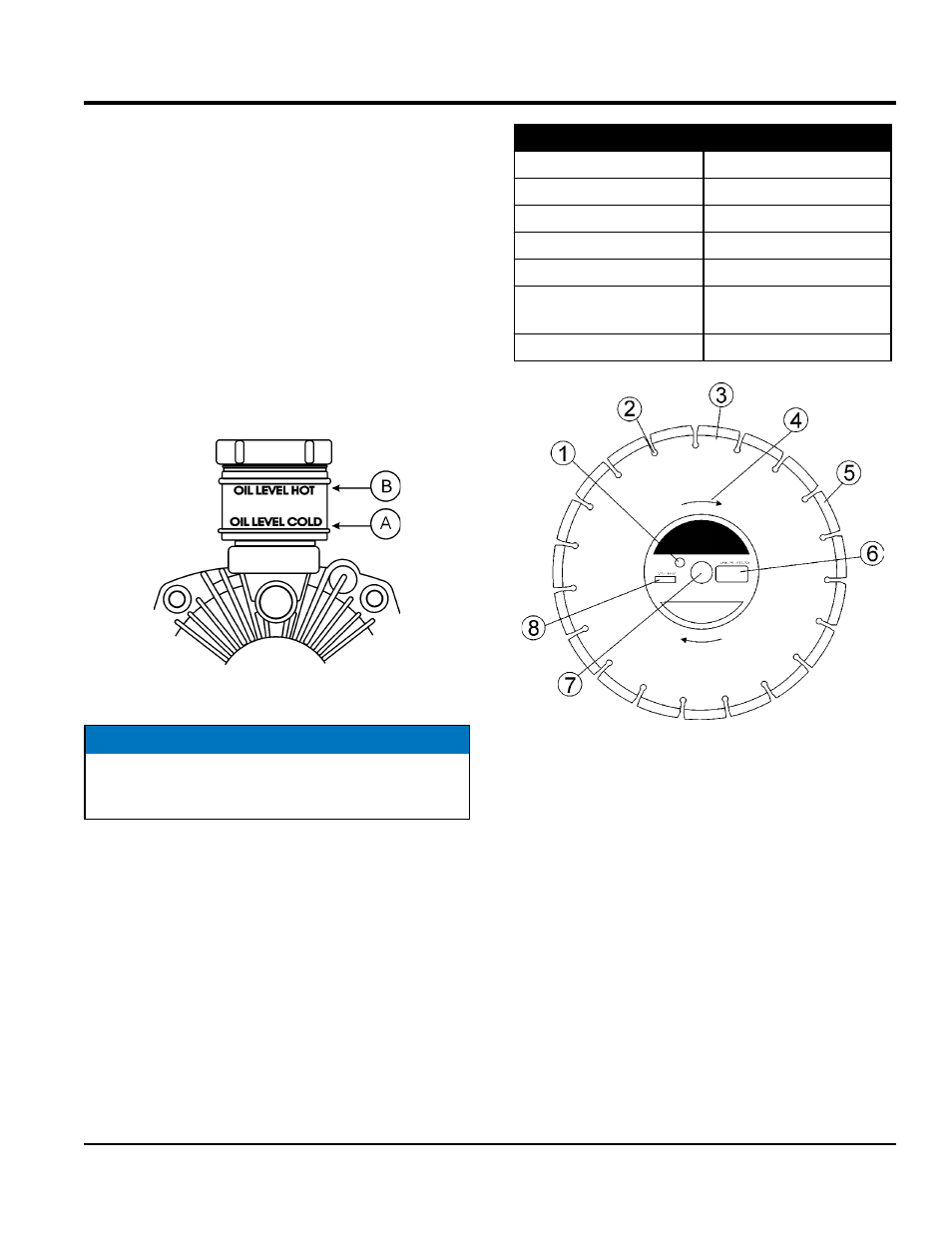

2. Note the level marks on the reservoir (Figure 7). It is

essential to reference the existing oil conditions (A) cold

or (B) hot prior to operating the saw.

Do NoT over fill

the fluid reservoir.

Figure 7. Transmission Reservoir

BlaDe iNSpeCTioN

This saw is to use the following type of blades only:

Steel Core Segmented or Continuous Diamond

Rim Cutting Wheel

Any other type of blade (tool) is not to be used. See Table

5 for specific blade usage for different materials.

Perform the blade inspection as described. Refer to Figure 8

for the location.

NOTICE

Overfilling the transmission with hydraulic fluid may

cause the seals to rupture causing mechanical damage.

inspectiOn

Figure 8. Diamond Blade Inspection Points

1.

Drive pin hole — A commonly located hole on the

diamond blade core that prevents operational blade

slippage between the inner and outer blade flanges

(collars). Inspect the diameter of the hole to ensure

there is no distortion and that a snug fit develops

between the hole and drive pin.

2.

Stress relief holes (gullets) — Check the steel core

for cracks that may have propagated from the slots

and/or gullets. Cracks indicate extreme fatigue failure

and if sawing continues, catastrophic failure will occur.

3.

edge of The Steel Core — Check the diameter

edge for discoloration (blue oxidation) indicating an

overheating condition caused by insufficient cooling

water/air. Overheating of blades may lead to loss of

core tension and increase the possibility for blade

failure. Check to make sure the steel core’s width is

Table 5. Material listing and Blade Selection

Material

Blade

Cured Concrete

Cured Concrete Blade

Green Concrete

Green Concrete Blade

Asphalt

Asphalt Blade

Asphalt over Concrete

Asphalt/Concrete Blade

Block, Brick, Masonry,

Refractories

Masonry Blade

Tile, Ceramic, Stone

Tile Blade