Maintenance, Installing pans onto finisher blades, Long-term storage – Multiquip J36E2 User Manual

Page 28: Variable speed pulley general description

page 28 — J36e2 elecTric WalK-BeHiND TrOWel • OperaTiON aND parTs maNUal — rev. #0 (07/24/12)

iNsTalliNg paNs ONTO FiNisHer BlaDes

These round discs, sometimes referred to as "pans", attach

to the spiders arms and allow early floating on wet concrete

and easy movement from wet to dry areas. They are also

very effective in embedding large aggregates and surface

hardeners.

Refer to Figure 28 when installing pans onto finisher blades.

Figure 28. Z-Clip Finisher Pan Installation

1. Lift trowel just enough to slide pan under blades. Lower

finisher onto pan with blades adjacent to Z-Clips.

2. Rotate blades into position under Z-Clips. Ensure that

the blades are rotated in the direction of travel when

the machine is in operation or use the engine to rotate

the blades into position.

3. Attach the blade tie-downs to the far side of the Z-Clip

brackets with tie-down knobs as shown in Figure 28.

4. Check to make certain that the blade edges are

secured under the Z-Clips and the tie-downs are

secured completely over the edges of the blade bar

before the machine is put back into operation.

lONg-Term sTOrage

For storage of the trowel for over 30 days, the following is

required:

Clean all external parts of the trowel with a cloth.

Cover the trowel and store in a clean, dry place.

BLADE ASSEMBLY

Z-CLIP, PAN

TIE-DOWN, BLADE

KNOB, TIE-DOWN

Z-CLIP PANS

MaintenanCe

variaBle speeD pUlley

general Description

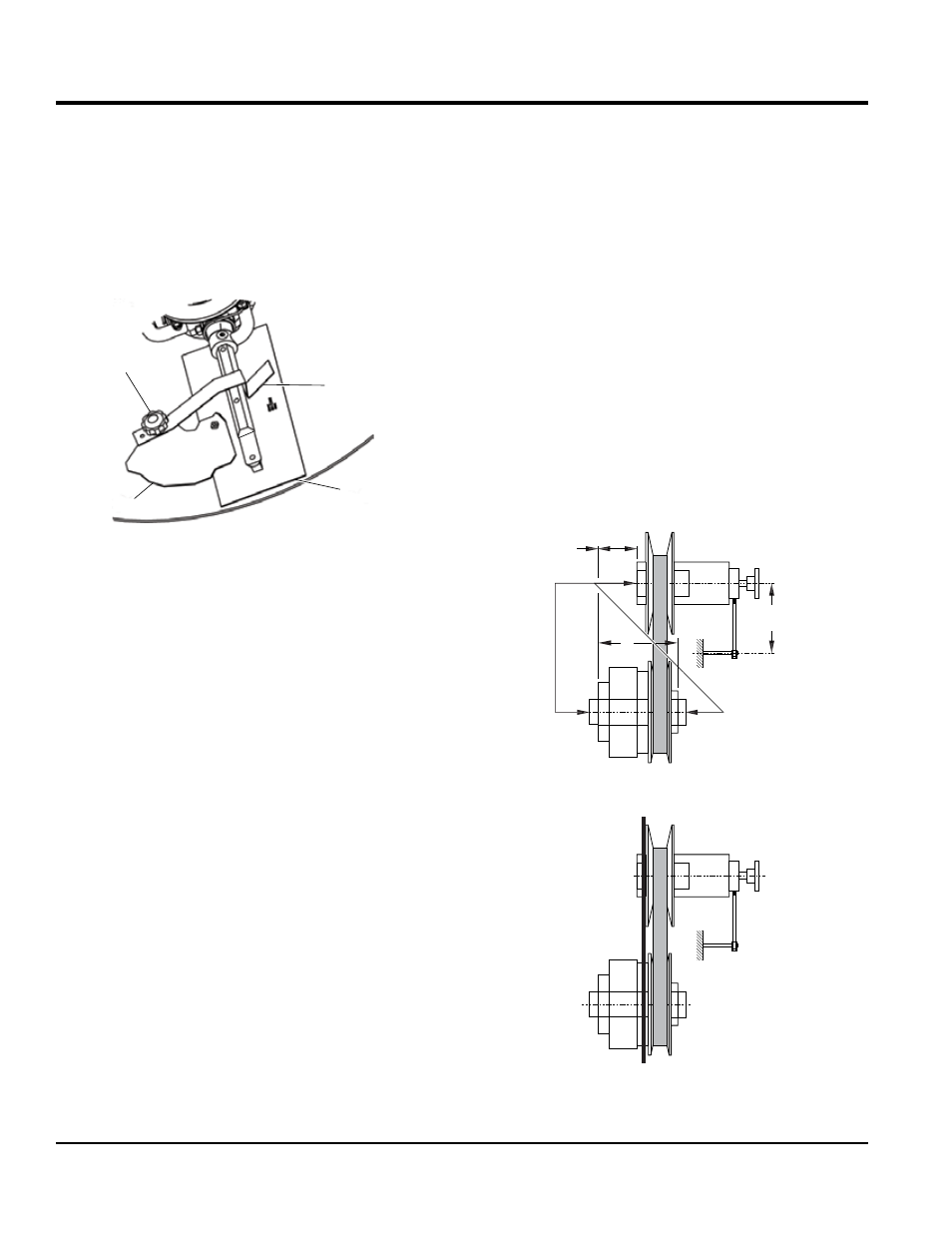

A fixed center distance compound drive consists (Figure 29)

of one cam stabilized automatic variable pulley, one manually

controlled pulley and a standard "V" belt or a variable speed

belt.

The speed adjustment is accomplished by turning the

leadscrew of the manually controlled pulley. As the faces

contract, the belt is forced to a larger diameter in the

manual pulley and consequently to a smaller diameter in

the automatic pulley.

Compound center distance drives may be "C" mounted,

both driving and driven shafts pointed in the same direction,

or "Z" mounted, driving and driven shafts opposed.

The manually controlled pulley must be mounted on the

driver shaft.

Figure 29. Pulley Orientation

DRIVER PULLEY

DRIVEN PULLEY

“Z” MOUNTED

I

“MAX”

L

J

“C” MOUNTED

STRAIGH

T EDGE