Maintenance, Trowel arm removal, Checking trowel arm straightness – Multiquip J36E2 User Manual

Page 26: Trowel arm lever adjustment

page 26 — J36e2 elecTric WalK-BeHiND TrOWel • OperaTiON aND parTs maNUal — rev. #0 (07/24/12)

MaintenanCe

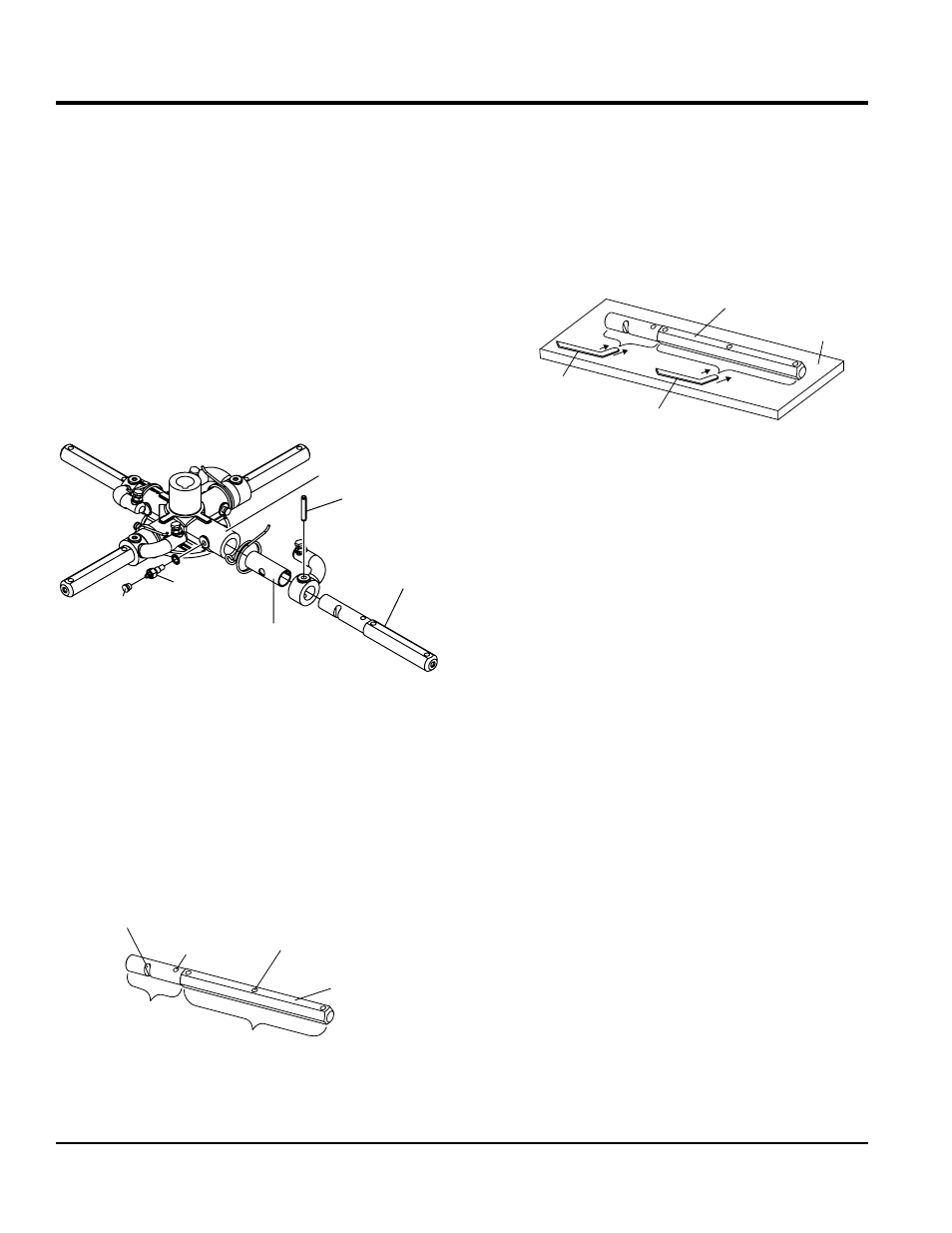

TrOWel arm remOval

1. Each trowel arm is held in place at the spider plate

by a hex head bolt (zerk grease fitting) and a roll

pin. Remove both the hex head bolt and the roll

pin (Figure 24) from the spider plate.

2. Remove the trowel arm from the spider plate.

3. Should the trowel arm inserts ( bushing ) come out with

the trowel arm, remove the bushing from the trowel arm

and set aside in a safe place. If the bushing is retained

inside the spider plate, carefully remove the bushing

4. Examine the trowel arm bushing insert (Figure 24),

clean if necessary. Replace bushing if out of round or

worn.

Figure 24. Trowel Arm Removal

cHecKiNg TrOWel arm sTraigHTNess

Trowel arms (Figure 25) can be damaged by rough

handling, such as dropping the trowel on the pad, or by

striking exposed plumbing, forms, or rebar while in

operation. A bent trowel arm will not allow the trowel to

operate in a smooth fluid rotation. If bent trowel arms are

suspect, check for flatness as follows:

Figure 25. Trowel Arm

TROWEL

ARM

ROLL PIN

SPIDER PLATE

ZERK

GREASE

FITTING

CAP

BUSHING

TROWEL ARM

ROUND SHAFT

SECTION

ROLL PIN

HOLE

BLADE ATTACHMENT

BOLT HOLE

FLAT OF HEXAGONAL

SHAFT (TOP OF ARM)

LEVER

MOUNTING

SLOT

TROWEL ARM

HEXAGONAL (HEX)

SHAFT SECTION

1. Use a thick steel plate, granite slab or any surface

which is true and flat, to check all six sides of each

trowel arm for flatness (Figure 26).

2. Check each of the six sides of the trowel arm (hex

section). A feeler gauge of .004 inch (0.10 mm) should

not pass between the flat of the trowel arm and the test

surface along its length on the test surface.

Figure 26. Checking Trowel Arm Flatness

3. Next, check the clearance between the round shaft

and the test surface as one of the flat hex sections of

the arm rests on the test surface. Rotate the arm to

each of the flat hex sections and check the clearance

of the round shaft. Use a feeler gauge (Figure 27) of

.005 inch (0.127 mm). Each section should have the

same clearance between the round of the trowel arm

shaft and the test surface.

4. If the trowel arm is found to be uneven or bent, replace

the trowel arm.

TrOWel arm lever aDJUsTmeNT

The easiest and most consistent wASSY. to adjust the

trowel arm lever is to use the Trowel Arm Adjustment

Fixture (P.N. 1817).

As each trowel arm is locked into the fixture, the arm bolt

is adjusted to where it contacts a stop on the fixture. This

will consistently adjust all of the trowel arms, keeping the

finisher as flat and evenly pitched as possible.

This fixture will allow consistent adjustment of the trowel

arm lever. It comes with all the hardware necessary to

properly accomplish this maintenance and instructions on

how to properly utilize this tool. Adjusting the trowel arm

lever without a fixture requires a special talent.

Perform the following procedure when adjusting the trowel

arm lever:

TROWEL

ARM

TROWEL

ARM

FLAT TEST

SURFACE

FEELER GAUGE

(.004 IN/0.10 MM)

FEELER GAUGE

(.005 IN/0.127 MM)