Assembly and installation – Multiquip J36E2 User Manual

Page 18

page 18 — J36e2 elecTric WalK-BeHiND TrOWel • OperaTiON aND parTs maNUal — rev. #0 (07/24/12)

5. Using a wrench, tighten the brass set #2 nut up against

the yoke boss. This will lock the cable in place.

6. Use a wrench and finish tightening the brass set #1

nut up against the yoke boss.

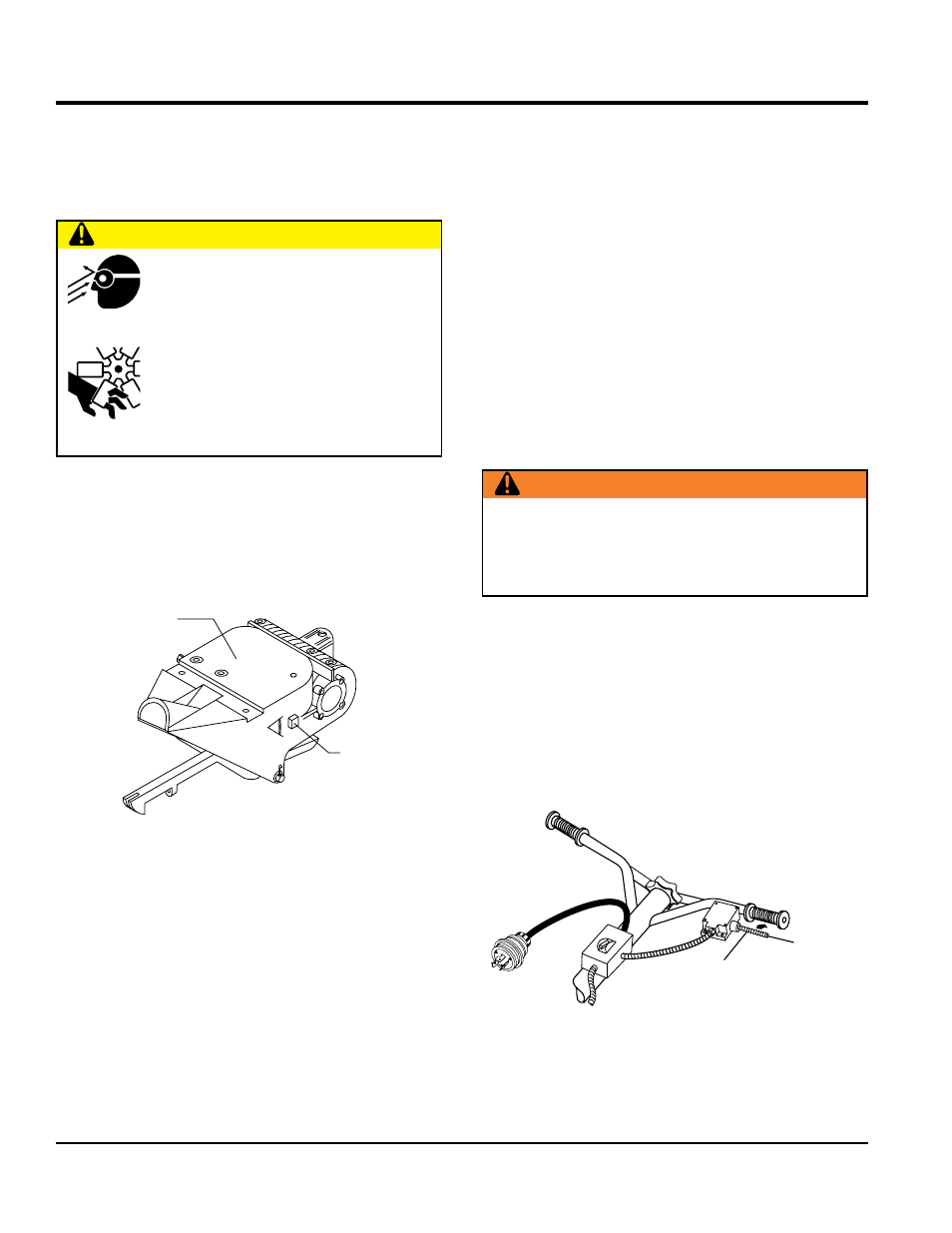

gearbox Oil

1. Determine if the gearbox oil is low by removing the oil

plug located on the side of the gearbox. (Figure 8) This

plug will be marked by the "check" decal. The correct

level of the lubrication oil should be to the bottom of

the fill plug.

Figure 8. Gearbox

2. If lubrication oil begins to seep out as the drain plug

is being removed, then it can be assumed that the

gearbox has a sufficient amount of oil.

3. If lubrication oil does not seep out as the drain plug

is being removed, fill with type ISO 680 (P/N 10139)

gearbox lubricant oil until the oil filler hole overflows.

caUTiON

alWays wear approved eye and hearing

protection before operating the trowel.

Never place hands or feet inside the

guard rings while the electric motor is

running.

alWays remove power from the

electric motor before performing any kind of

maintenance on the trowel.

OIL FILL

PLUG

GEARBOX

asseMbly and installatiOn

v-Belt check

A worn or damaged V-belt can adversely affect the

performance of the trowel. If a V-belt is defective or worn

simply replace the V-belt as outlined in the maintenance

section of this manual.

Belt guard check

Check for damage, loose or missing hardware.

Blade check

Check for worn or damaged blades. Check to see if one

blade is worn out while the others look new. If this is

the case there could be a blade pitch problem. Refer to

the maintenance section of this manual for blade pitch

adjustment procedure. Replace any worn blades.

Operator presence ON/OFF lever switch

This trowel has been equipped with an operator presence

ON/OFF lever switch (Figure 9). This switch should be

tested every time the motor is started.

The purpose of this switch is to stop the electric motor in

a runaway. situation, (i.e. the operator releasing the handle

during operation).

Figure 9. Operator Presence Switch

WarNiNg

Never disable or disconnect the safety "operator

presence" ON/OFF lever switch. It is provided for

operator safety. Injury may result if it is disabled,

disconnected or improperly maintained.

OPERATOR

PRESENCE

ON/OFF

LEVER SWITCH

POWER

ON

OFF

(CENTER)