Assembly and installation, Handle tube installation, Pitch cable installation – Multiquip J36E2 User Manual

Page 17

J36e2 elecTric WalK-BeHiND TrOWel • OperaTiON aND parTs maNUal — rev. #0 (07/24/12) — page 17

asseMbly and installatiOn

assemBly aND iNsTallaTiON

Before the trowel can be put into operation there are some

components that must be installed before the trowel can

be used. This section provides general instructions on how

to install those components.

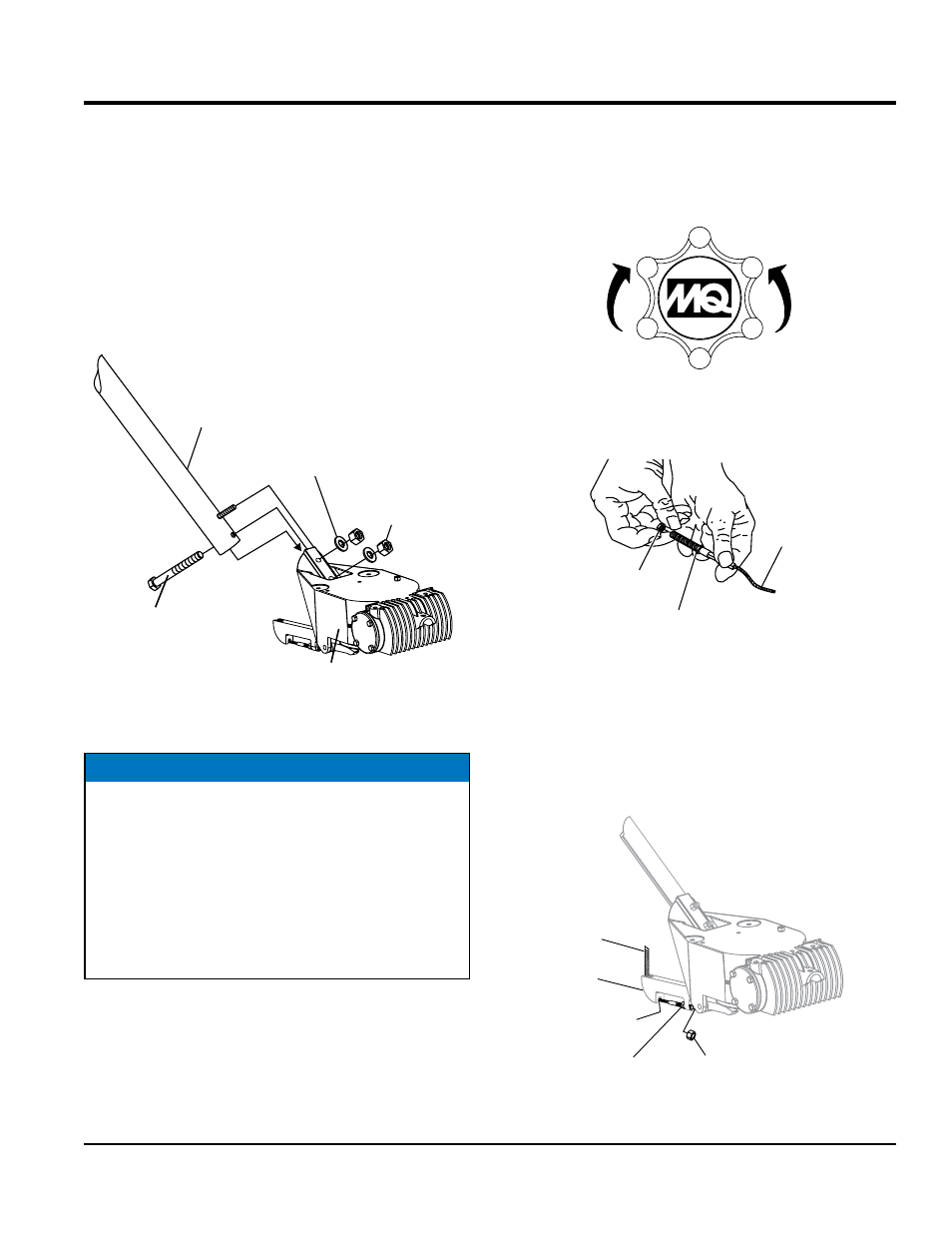

Handle Tube installation

1. Attach the main handle (tube) to the gearbox as shown

in (Figure 4). The mounting hardware should be

contained in the shipping container.

Figure 4. Handle Tube Installation

3/8 FLAT

WASHER

3/8-16

NYLOC NUT

3/8-16 X 3.25

HHC SCREW

MAIN HANDLE

(TUBE)

GEARBOX

NOTICE

If additional handle height adjustment is desired, a

handle wedge kit can be purchased for your trowel by

ordering P/N 2576 from your Multiquip dealer.

These wedges are placed between the handle and the

gearbox to adjust the operating height of the handle.

This kit comes complete with wedges, new bolts and

installation instructions. This will move your operating

handle position up or down approximately 3” (76 mm).

pitch cable installation

1. Expose the pitch cable to maximum by turning the

blade pitch star wheel (Figure 5) fully counterclockwise

for no pitch (blades flat).

Figure 5. Blade Pitch Star wheel

2. Remove brass set nut #1 from the blade pitch cable

end as shown in (Figure 6).

Figure 6. Blade Pitch Cable

3. Thread brass set nut #2 (Figure 6) towards the cable

as far as possible.

4. Insert the cable end through the yoke eyelet

(Figure 7). Tighten brass set nut #1 by hand to remove

all the slack from the cable.

Figure 7. Pitch Cable Yoke Attachment

INCREASE

BLADE PITCH

(CW)

DECREASE

BLADE PITCH

(CCW)

BLADE

PITCH

CABLE

BRASS SET

NUT #1

BRASS SET

NUT #2

BRASS SET

NUT #1

BRASS SET

NUT #2

YOKE

EYELET

YOKE

BLADE

PITCH

CABLE