Multiquip LS-50TD User Manual

Page 49

MAYCO LS-40D/LS-40TD/LS-50TD PUMP — OPERATION AND PARTS MANUAL — REV. #11 (09/16/11) — PAGE 49

TIRES/WHEELS/LUG NUTS

Tires and wheels are a very important and critical compo-

nents of the trailer. When specifying or replacing the

trailer wheels it is important the wheels, tires, and axle are

properly matched.

LS-40D/LS-40TD/LS-50TD PUMP — MAINTENANCE (TRAILER)

DO NOT attempt to repair or modify a wheel. DO

NOT install an inter-tube to correct a leak through

the rim. If the rim is cracked, the air pressure in the

inter-tube may cause pieces of the rim to explode

(break-off) with great force and can cause serious

eye or bodily injury.

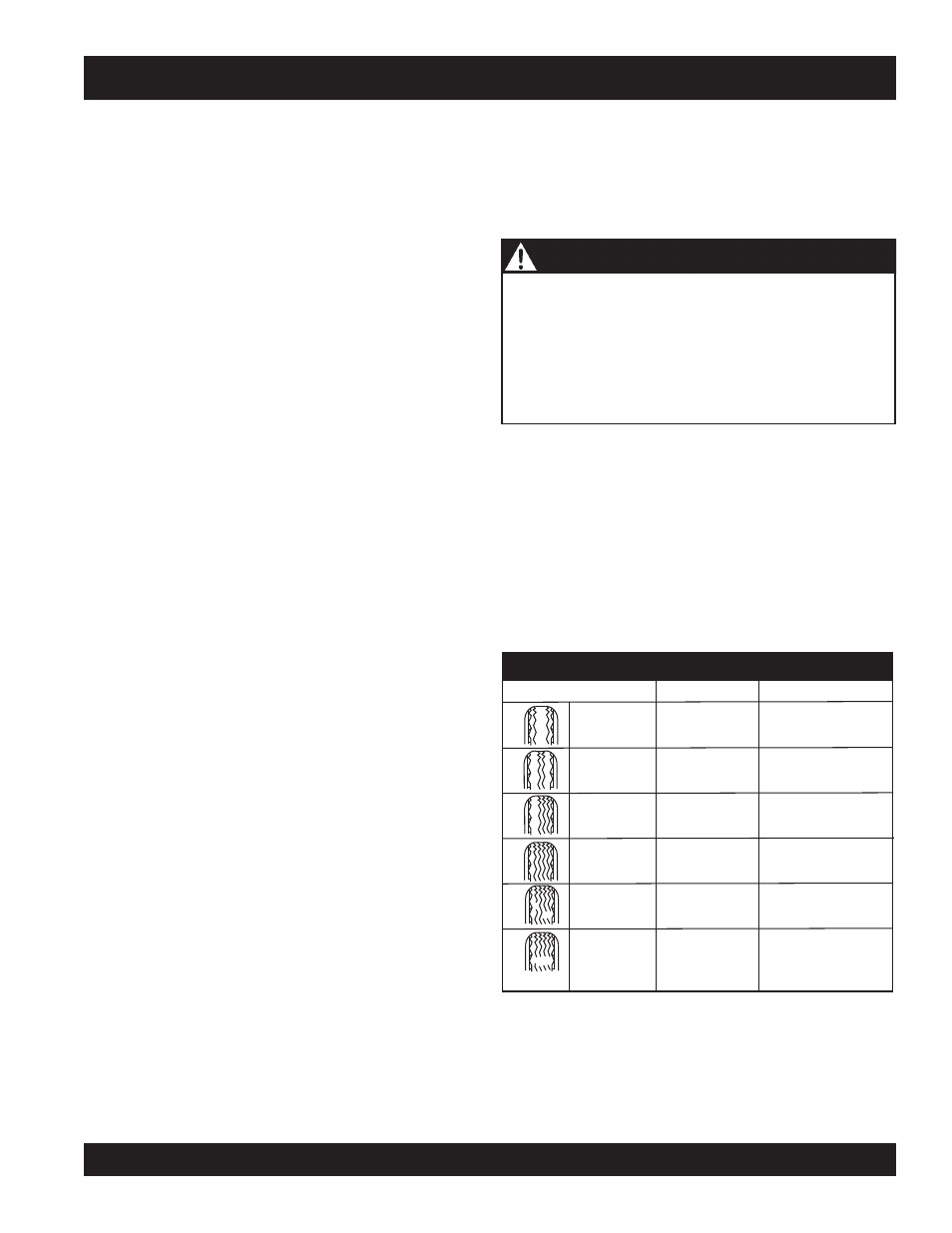

WEAR PATTERN

SOLUTION

CAUSE

Center Wear

Over Inflation

Adjust pressure to

particular load per

tire manufacturer.

Edge Wear

Under Inflation

Make sure load does

not exceed axle rating.

Align wheels.

Side Wear

Adjust pressure to

particular load per

tire manufacturer.

Loss of chamber

or overloading.

Toe Wear

Incorrect toe-in

Align wheels.

Cupping

Out-of balance

Check bearing adjust-

ment and balance tires.

Flat Spots

Wheel lockup &

tire skidding.

Avoid sudden stops

when possible and

adjust brakes.

TABLE 6. TIRE WEAR TROUBLESHOOTING

TIRES WEAR/INFLATION

Tire inflation pressure is the most important factor in tire

life. Pressure should be checked cold before operation. DO

NOT bleed air from tires when they are hot. Check inflation

pressure weekly during use to insure the maximum tire life

and tread wear.

Table 6 (Tire Wear Troubleshooting) will help pinpoint the

causes and solutions of tire wear problems.

CAUTION - TRAILER WHEEL MAINTENANCE

TRAILER ACTUATOR

The following maintenance steps should be performed

before towing the pump:

1. Frequently check actuator brake fluid levels. (Fluids

must be approved, clean, and uncontaminated). Use

DOT 3 or 4 brake fluid.

2. Make sure actuator mounting bolts and coupler bolts

are secure.

3. Periodically check the brake system as descrubed in

the brakes owner’s manual. Consult certified brake

specialists to make necessary adjustments or repairs.

Failure to do so could result in loss of braking capa-

bilities.

Servicing the Actuator Emergency Lever

If the actuator emergency lever is applied, disengage

using a screwdriver to lift upward on the front of the flat

emergency lever spring while pulling the lever forward until

it has been released.

Replace damaged parts as follows:

1. Remove the Master Cylinder and Push Rod Assembly.

Be careful not to get dirt into the master cylinder. A

new Master Cylinder Gasket should be used when re-

installing.

2. Remove the Cable S-hook from the Emergency Lever,

the Emergency Lever Guide, and the Flat Emergency

Lever Spring, then pull the lever out of the actuator

outer case through the cross-slot at the top of the

case.

3. Install a new emergency lever through the cross-slot

in the actuator casing. Attach a new emergency lever

spring and emergency lever guide.

4. Install a new master cylinder gasket to the master

cylinder. Put the push rod assembly and master

cylinder back into the outer case of the actuator.

5. Set the S-hook onto the emergency brake cable and

insert into the emergency lever. Squeeze the s-hook

shut to secure it to the lever.

6. Add adequate brake fluid to the master cylinder and

bleed the brake system.