Multiquip LS-50TD User Manual

Page 22

PAGE 22 — MAYCO LS-40D/LS-40TD/LS-50TD PUMP — OPERATION AND PARTS MANUAL — REV. #11 (09/16/11)

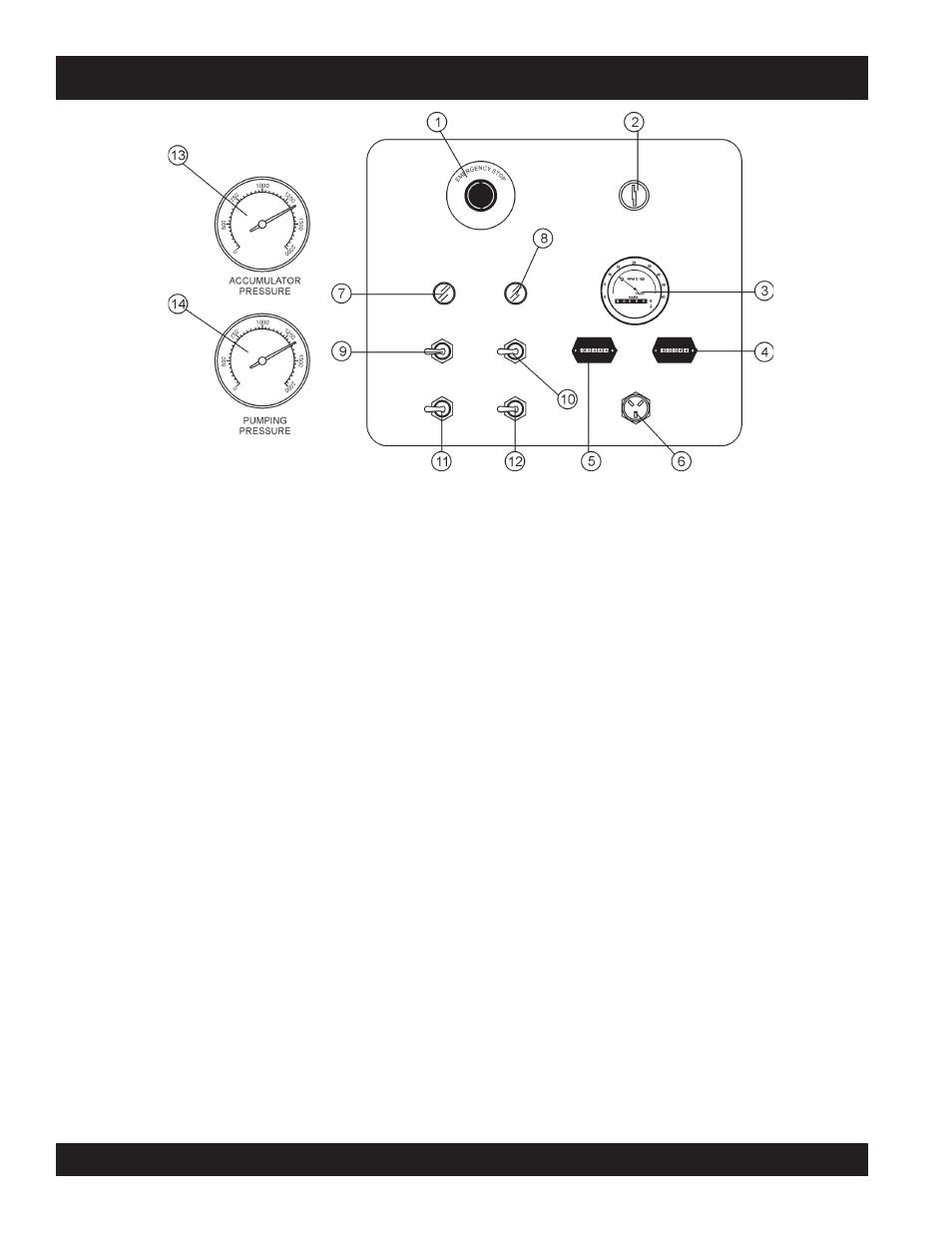

LS-40D/LS-40TD/LS-50TD PUMP — CONTROL BOX COMPONENTS

Figure 7. Pump Control Box Components

1.

Emergency Stop Button – Press emergency stop

button to stop pump in an emergency. Turn knob counter

clockwise to disengage the stop button.

2.

Ignition Switch – Insert the ignition key here to start

the engine. Turn the key clockwise to the ON position,

then continue turning clockwise to the START position

and release. To stop the engine turn the key fully counter-

clockwise to the STOP position.

3.

Engine Tachometer – Monitors the engine RPM’s

4.

Engine Hour meter – Display's the number of hours

the engine has been in use.

5.

Pump Hour meter – Display's the number of hours

the pump has been in use.

6.

Remote Cable Connector – Insert the remote control

input cable into this connector.

7.

Battery Indicator Lamp– Indicates a low battery

charge.

Replace or charge battery. NEVER operate the

pump when this lamp is on.

8.

Oil Pressure Indicator Lamp – Indicates incorrect

operational pressure for running the pump. NEVER

operate the pump if this lamp is ON.

9.

Direction Control Switch– This 2 position switch

controls the direction of flow for any mix in the pump.

The

left most position sets the pumping direction to

forward and the

right most position sets the pumping

direction to reverse.

10. Pumping Control Switch – This 3-position switch

controls the pumping of the pump. The

right most

position is for use with the remote control unit, the

left

most position is for normal pumping operation, and the

center most position (OFF) prevents pumping.

11. Cylinder Stroke Control Switch - This three position

switch controls the pumping function. The

left most

position sets the pump to

automatic cycling. Set the

switch to this position for normal pump operation.

The

right most position changes the pump from

automatic to

manual cycling. This allows the cylinders

to be manually cycled using the

Manual Cylinder

Jogging Switch.

12. Manual Cylinder Jogging Switch – This 2 position

switch allows the operator to manually jog the cylinders

to assist in clearing material line packs and is used to

test pumping pressure (See

Initial Start-up Procedure

section of this manual for testing procedure).

The

left most position jogs Cylinder “A” and the right

most position jogs Cylinder “B”.

13. Accumulator Pressure Gauge - This gauge monitors

the system pressure of the Accumulator tank. Normal

system pressure should read approximately 1750 PSI

during pumping.

14. Main Pressure Gauge - This gauge monitors the

system pressure while pumping material. The maximum

pressure rating is 3200 PSI ± 50.