Multiquip LS-50TD User Manual

Page 30

PAGE 30 — MAYCO LS-40D/LS-40TD/LS-50TD PUMP — OPERATION AND PARTS MANUAL — REV. #11 (09/16/11)

LS-40D/LS-40TD/LS-50TD PUMP — OPERATING PROCEDURES

OPERATING PROCEDURES

Getting the concrete to flow through

the hose at the start of the pumping

cycle can be one of the most critical

operations of the pour. (

Manually

operate the throttle when starting,

NOT REMOTELY)

Safety glasses MUST be worn at

all times when operating the pump.

Failure follow safety guidelines can

result in

serious injury.

WARNING - SAFETY GLASSES

A well-planned location of the pump and

routing of the hose before starting a pour may

save subsequent moves throughout the job.

HOSE LUBRICATION

This procedure lubricates the hose and prevents separation

and blockages in the hose. Inspect the lines at all times to

prevent problems.

Before concrete is discharged into the hopper, it is suggested

that 3 to 4 gallons of water be sprayed into the hopper,

followed by approximately 5 gallons of a creamy cement and

water slurry (1/2 bag of cement to 5 gallons of water).

The bentonite is not compatible with concrete.

DO NOT pump it into the forms discharge it

out of the formed area.

PRIMING THE PUMP WITH SLURRY MIXTURE

It is CRITICAL to the successful operation of a concrete

pump that the manifold and all delivery hoses, pipes and

elbows are coated with a film of lubrication BEFORE you

attempt to pump concrete.

Failure to properly prepare the pump and system will result

in a “dry pack” of concrete, blocking the shuttle valve tube

or delivery line.

1. Connect the entire delivery system to the pump,

except

for the first hose. Pour 5 gallons of water into the second

hose and push in your clean out ball and reconnect.

This will help hold back the prime.

3. Mix the prime to the consistency of a smooth batter.

4. Position the first ready-mix truck at the hopper. Check

the concrete. DO NOT discharge concrete into hopper

at this time.

5. Pour approximately two 5 gallon buckets of prime into

the first hose and connect it to the pump.

2. There are several things you can use for the prime. A

few examples are Cement and lime at a 50/50 mixture,

slick pac, bentonite clay.

PRESSURE TEST

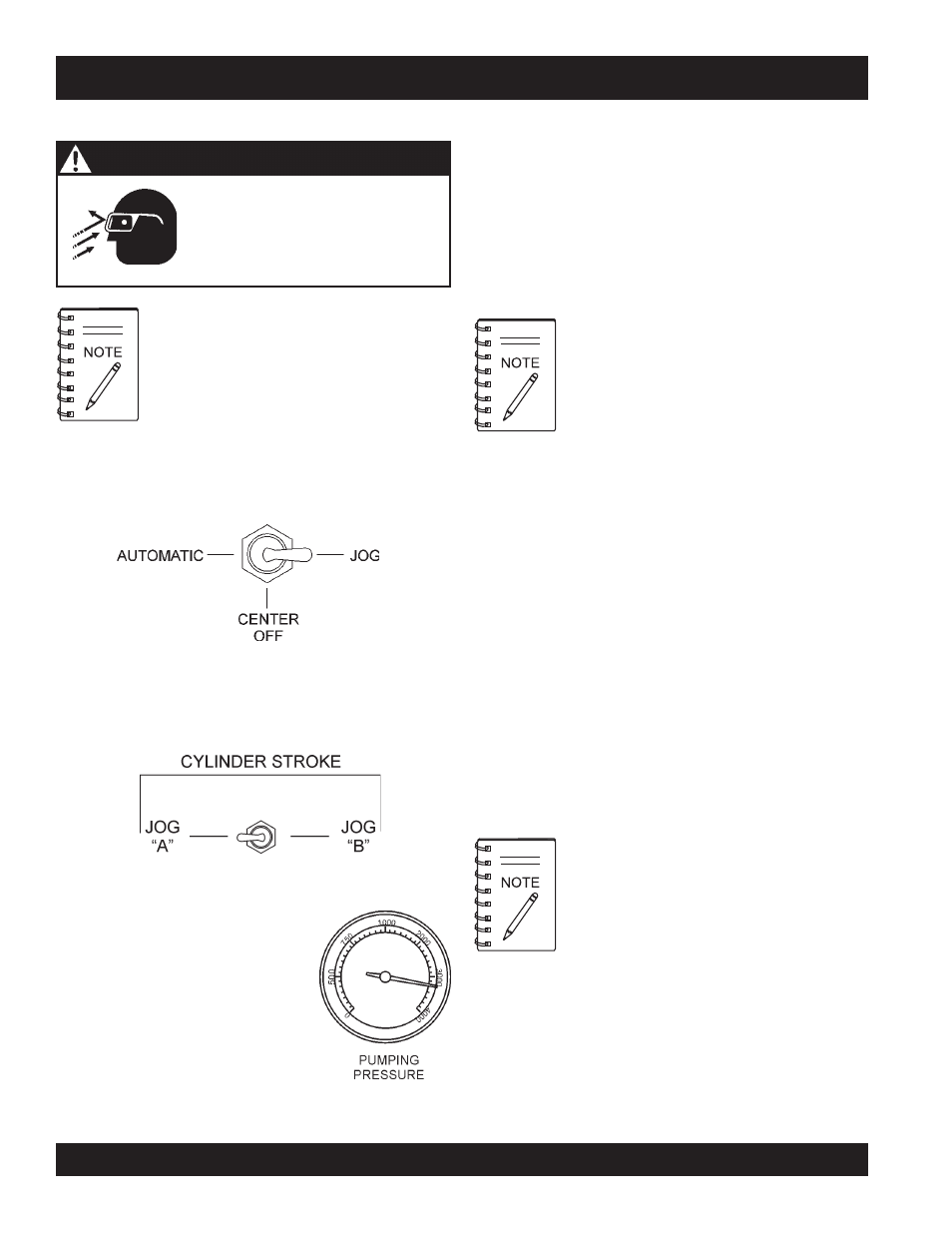

1. To determine the pressure of the Hydraulic System, set

the

Cylinder Stroke Control switch (Figure 31) to the

JOG possition.

Figure 32. Manual Cylinder Jogging Switch

13. The Pumping Pressure Gauge

(Figure 33) should read

approximately 3200 ± 50 PSI.

Figure 33. Pumping

Pressure Gauge

2. Turn and hold the Manual Cylinder Jogging Switch

(Figure 32) to either JOG “A” or JOG “B” position to

test the pressure of that cylinder.

Figure 31. Manual Cylinder Jogging Switch