Maintenance (mixer), Lug nut torque requirements – Multiquip WM63h8 User Manual

Page 31

wm63-series mixer • operaTion and parTs manual — rev. #0 (069/27/12) — page 31

Maintenance (Mixer)

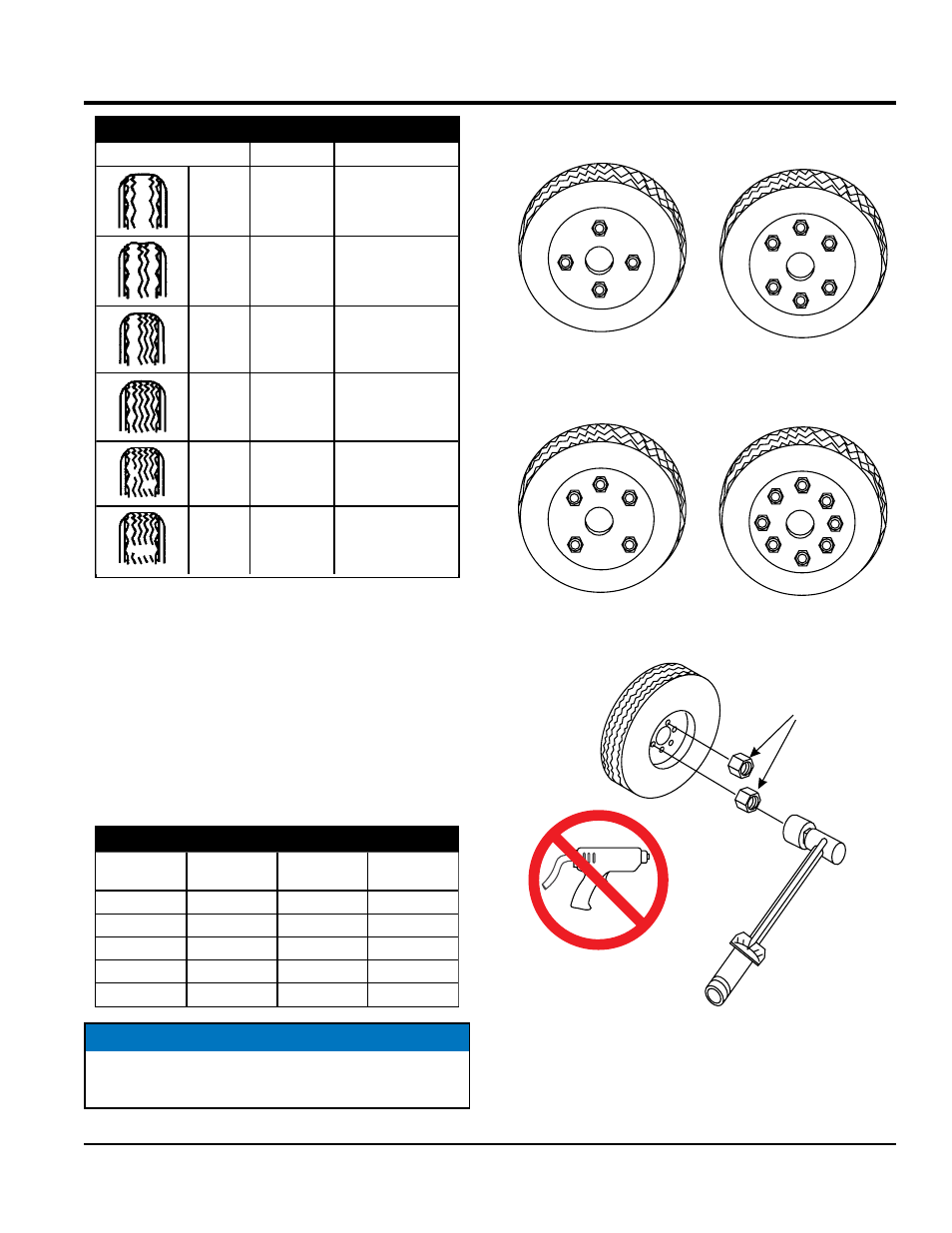

lug nut Torque requirements

It is extremely important to apply and maintain proper

wheel mounting torque. Be sure to use only the fasteners

matched to the cone angle of the wheel. Proper procedure

for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 37.

do noT

torque the wheel lug nuts all the way down. Tighten each

lug nut in 3 separate passes as defined by Figure 37.

Table 9. Tire wear Troubleshooting

Wear Pattern

Cause

Solution

Center

Wear

Over Infl ation

Adjust pressure to

particular load per

tire manufacturer

Edge

Wear

Under

Infl ation

Adjust pressure to

particular load per

tire manufacturer.

Side

Wear

Loss of

chamber or

overloading

Make sure load does

not exceed axle

rating. Align wheels.

Toe

Wear

Incorrect

toe-in

Align wheels.

Cupping Out of

balance

Check bearing

adjustment and

balance tires.

Flat

Spots

Wheel lockup

and tire

skidding

Avoid sudden stops

when possible and

adjust brakes.

Table 10. Tire Torque requirements

wheel size

First pass

FT-lBs

second pass

FT-lBs

Third pass

FT-lBs

12"

20-25

35-40

50-65

13"

20-25

35-40

50-65

14"

20-25

50-60

90-120

15"

20-25

50-60

90-120

16"

20-25

50-60

90-120

NOTICE

never use an pneumatic air gun to tighten wheel

lug nuts.

3. After first road use, retorque all lug nuts in sequence.

Check all wheel lug nuts periodically.

Figure 37. Wheel Lug Nuts Tightening

Sequence

1

3

2

4

4-LUG NUTS

1

3

2

5

4

5-LUG NUTS

1

3

5

2

4

6

6-LUG NUTS

2

4

1

8

8-LUG NUTS

3

7

5

6

LUG NUTS

TORQUE WRENCH

PNEUMATIC

AIR GUN