Maintenance – Multiquip MTR40F User Manual

Page 18

PAGE 18 — MTR40F RAMMER — OPERATION AND PARTS MANUAL — REV. #3 (01/05/12)

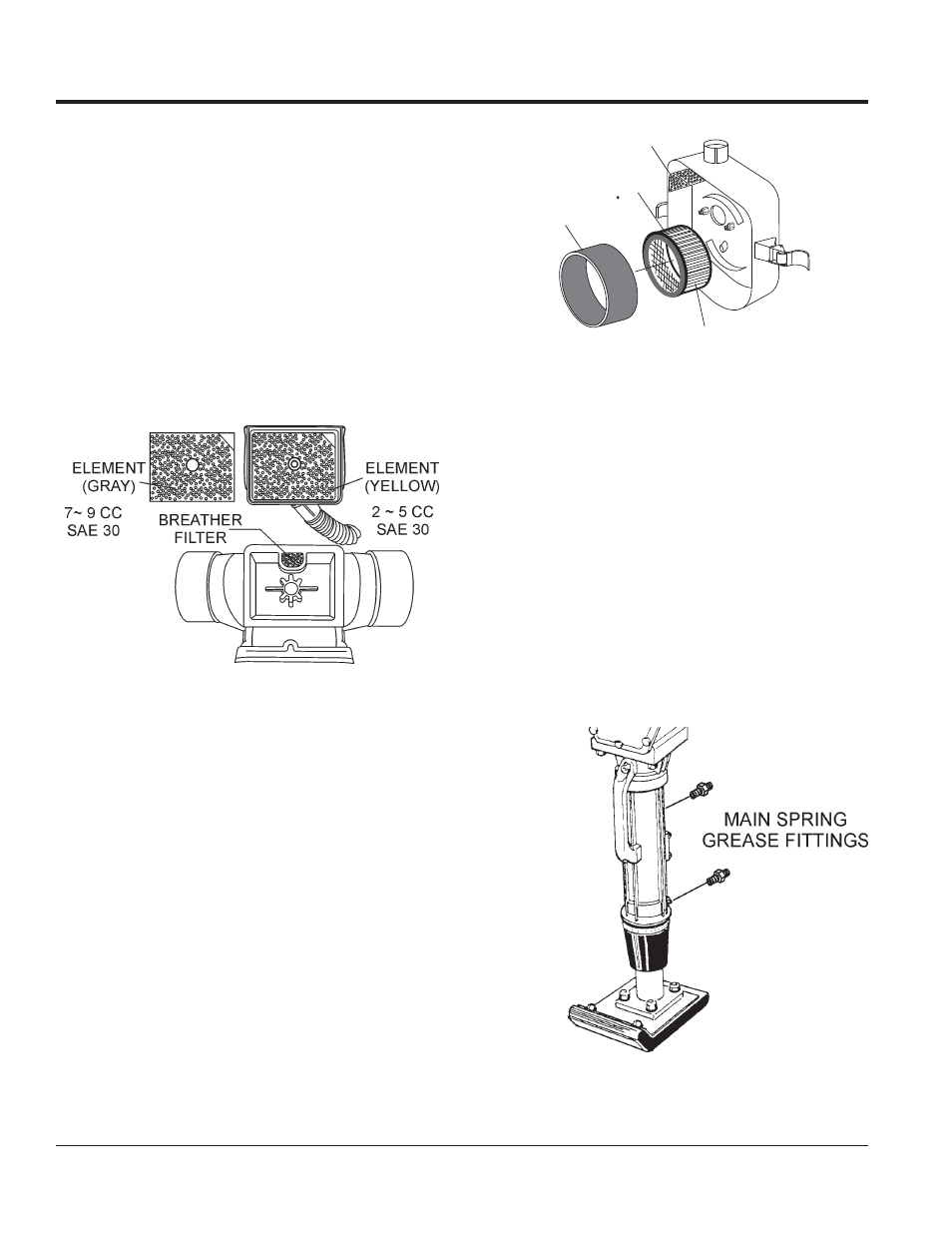

Figure 16. Primary Air Cleaner

Figure 17. Engine Air Cleaner

GRAY OUTER

FOAM ELEMENT

CLEAN WITH

KEROSENE

PAPER

ELEMENT

CLEAN WITH

SOLVENT

BREATHER

ELEMENT

Maintenance

Perform the scheduled maintenance procedures as defined by

Table 4 and below:

Daily

■ Thoroughly remove dirt and oil from the engine compartment

and rammer. Clean or replace the air cleaner elements as

necessary. Check and retighten all fasteners as necessary.

Check the bellows for oil leaks. Repair or replace as needed.

200 - 300 HOURS (Pre-Cleaner)

■ Remove the element from the pre-cleaner (Figure 16) at the

top of the crankcase (body side) and clean it with cleaning oil

(kerosene).

■ Lubricate the top element (yellow) with 2~5 cc of engine oil

SAE-30.

■ Lubricate bottom element (gray) with 7~9 cc of engine oil

SAE-30 and completely squeeze out the excess oil from the

element before installing.

Air Cleaner

■ The air cleaner (Figure 17) should be inspected and cleaned

on a regular basis at least once a week. Remove element,

rinse in soapy water, squeeze and allow to air dry until

completely dry before reinstalling.

■ Carefully tap the paper filter element (Figure 17) several times

on a hard surface until all dirt is removed then reinstall.

NEVER

brush off dirt. Brushing will force dirt into the fibers. Replace the

paper filter element if it is excessively dirty.

Main Springs Lubrication

■ The rammer

main springs

(Figure 18) should be lubricated

with five shots of grease with a hand grease gun after each

eight (8) hours of use.

■ Use MQ HIGH TEMPERATURE GREASE, P/N GRS2 or its

equivalent.

■ Equivalent greases include Shell Darina or Texaco

Thermatex, both of which have a bentone base and EP-2

rating.

■ If an inferior grease is used, it may become too thick or too

thin due to changes in temperature, and improper lubrication

could result.

Figure 18. Grease Fittings (Main Springs)

MAINTENANCE