MTS Series 311 Load Frame User Manual

Page 63

Aligning the Force Transducer

Series 311 Load Frame

Maintenance

63

C.

Slowly turn the actuator to rotate the indicator 360

° around the force

transducer.

Stop frequently to take indicator readings. Keep your hands off the

actuator and indicator when taking the readings. Compute the total

indicator runout (TIR). Take the maximum dial indicator reading and

subtract the minimum dial indicator reading.

D.

If the TIR is within the tolerance (as listed in the table

on page 63), the force transducer is accurately aligned with the

actuator. Go to Step 5.

If the TIR is greater than the tolerance, the force transducer needs to be

aligned with the actuator. Start over with Step 2.

3. Prepare the force transducer.

Loosen the jackbolts or setscrews in 1/4 turn steps to remove most of the

tension on the force transducer. Remove and lubricate each bolt one at a

time.

4. Align the force transducer.

This step describes how to align a force transducer to the crosshead.

A.

Lightly tap the transducer with the rubber mallet to change its position

until you get a TIR of 0.038 mm (0.0015 in) or less.

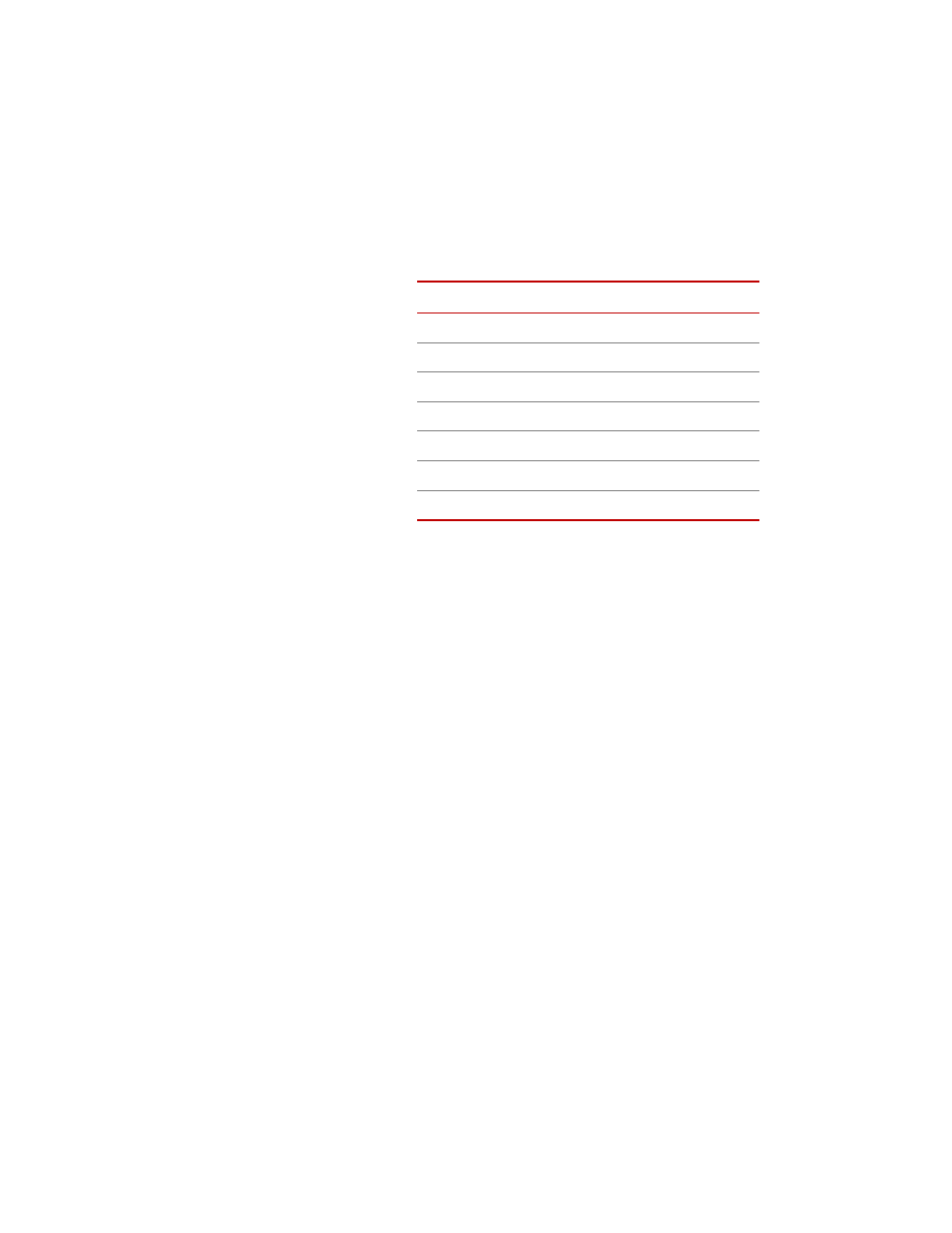

TIR Tolerance

Model

TIR

311.11

0.0381 mm (0.0015 in)

311.21

0.0508 mm (0.002 in)

311.31

0.0762 mm (0.003 in)

311.41

0.1016 mm (0.004 in)

311.51

0.1016 mm (0.004 in)

311.61

0.1016 mm (0.004 in)

311.71

0.1016 mm (0.004 in)