Impower series, Wall panel preparation – Metal Sales IMPower Series User Manual

Page 9

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

8

IMPower Series

TM

11.0 PANEL CUTTING PROCEDURES

11.1 Panels may be cut prior to installation or cut in-place. Metal Sales recommends cutting the panels prior to installation to minimize panel

damage and to ensure a good fit.

11.2 A Trumpf TPC 150-2 panel cutter or Milwaukee 6370-21 circular saw with an 8” diameter, 40 tooth carbide blade is recommended.

11.3 To perform a good cut, follow steps 1 through 4 shown below. If the panel thickness is greater than the saw's blade radius, cutting

should be done in two steps, cutting one side at a time; follow steps 1 through 6.

1. Measure the area to cut and mark a line on the panel surface.

2. Use adhesive tape on both sides of the cutting line to protect panel surface.

3. Recheck measurements and proceed with cutting operation.

4. Clean off any metal chips left on panel after cutting procedure. Any metal chips on the foam can be removed by hand.

5. If necessary, turn panel over and follow steps 1 through 4 for the other side of the panel.

6. File or sand off any burrs on the metal after cutting. The panel is now ready for installation. The installer must consider the

application of a continuous bead of sealant and, if necessary, the cutting of thermal breaks prior to installation; such tasks shall be

done on the ground.

Note: Do not use a reciprocating saw as friction between the cutting blade and the panel creates heat and may damage the painted

surface of the panel.

12.0 THERMAL BREAKS

12.1 Thermal breaks (cutting the interior metal skin) may be necessary to stop temperature conductivity in the panel. Consult your Metal

Sales representative for specific detail(s) and/or review the details in the shop drawings.

13.0 CAULKING / SEALANT PLACEMENT

13.1 Apply caulking to panel joinery as shown on the shop drawing details to provide a barrier against vapor and air infiltration. Caulking is

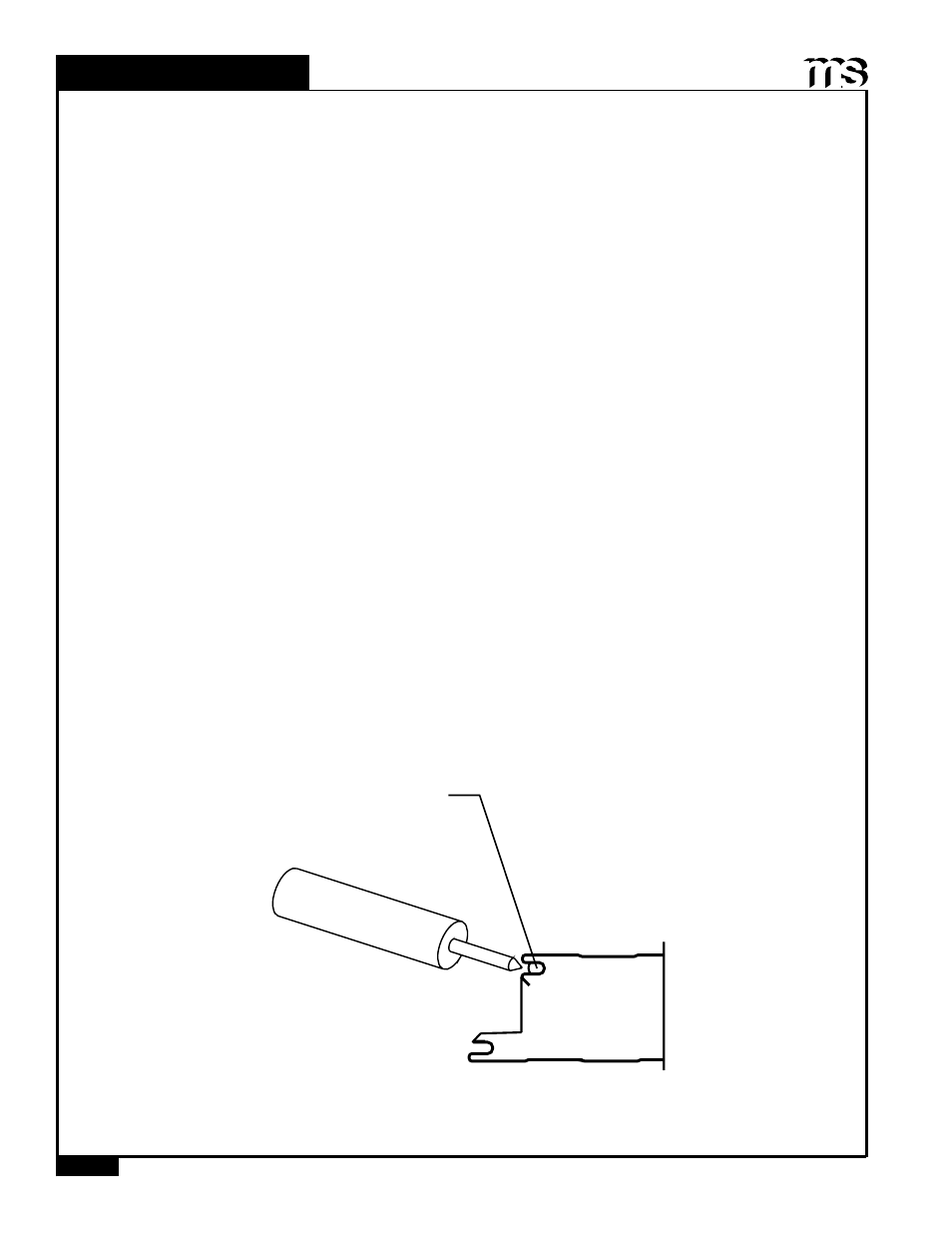

best applied while panels are lying flat. Apply beads of caulk immediately prior to engaging panels (see figure 5, below).

13.2 Caulking should be provided around panel openings and support steel where panel ends occur to develop vapor and air infiltration

seals. The beads of caulk on the support steel must be married to the beads of caulk in the panel joint.

Note: See joint detail(s) in the project shop drawings for job-specific caulking instructions.

Figure 5

Fill interior (liner) side cavity with

1

/

2

" diameter bead

(approximate) of non-skinning butyl sealant (Do not under-fill)

Butyl Sealant

Exterior

WALL PANEL PREPARATION

Non-Skinning

Interior