Impower series, Sr2 roof panel installation, Hand crimping tool – Metal Sales IMPower Series User Manual

Page 15

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

14

IMPower Series

TM

SR2 ROOF PANEL INSTALLATION

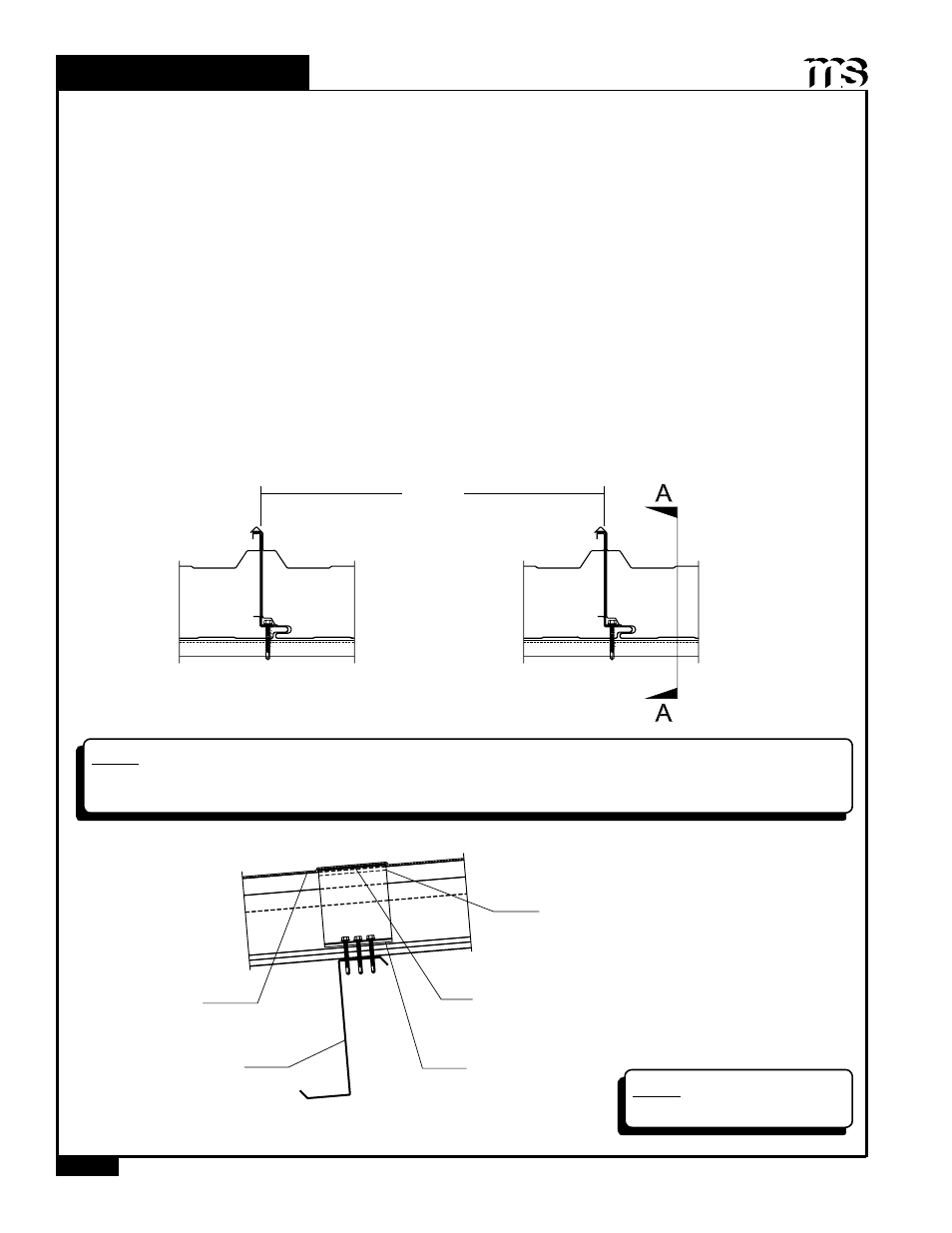

NOTE: Adjacent panel not

shown for clarity

Secondary framing

(not by Metal Sales)

SR2 roof panel clip w/

1

/

4

- Tek

no washer at each secondary support

Field applied 1/8" bead of butyl

sealant at underside of SR2 roof clip

Factory applied foam

gasket at underside of

SR2 roof clip

Section A-A

Clip Attachment

NOTE: Do not over-drive fasteners. If the metal at the edge of the panel is deformed out of plane, the adjacent

panel will be difficult to engage and will not seam. After SR2 Roof Clip has been installed over male leg of

standing seam panel, pre-crimp, using

1

/

2

" hand crimping tool.

40" nts

Figure 9

17.7 Square each panel before installing fasteners. Prior to installing, panels may need to be placed in a shaded area to prevent excessive

thermal bow which may hinder panel engagement.

17.8 If pre-drilling is required, use the drill bit sizes listed below.

Material

Fastener

Type

Drill

18 GA. to 16 GA.

1

/

4

- 14 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

5

/

32

" Pilot

14 GA.

1

/

4

- 14 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

3

/

32

" Pilot

12 GA.

1

/

4

- 14 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

#3 Drill

11 GA.

1

/

4

- 20 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

#3 Drill

3

/

16

" to

3

/

8

"

1

/

4

- 20 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

#1 Drill

3

/

8

" & Heavier

1

/

4

- 20 Hex Head Tek 3 Self-Drilling Fastener w/ Seal Washer

0.231" Pilot

17.9 Panels are to be fastened per the roof panel fastening schedule and calculations noted on the shop drawings. To install fastener, pre-

drill using the correct drill size (see 17.8, above). Prior to placing saddle washer, a bead of butyl caulk should be placed into the pilot

hole. Set the "SW-01" saddle washer in place and insert the fastener through the clip. Apply pressure to connection point by standing

directly on the overlapping hi rib panel to ensure that the joinery is fully nested and tighten down until assembly is snug. Use a 600 rpm

electric screw gun to drive fasteners. Do not use impact tools as these devices will over-tighten and cause damage.

17.10 The fastening pattern will depend on the panel thickness, span, substrate, and design loads. Consult your all weather insulated

panels representative or the factory for allowable panel and fastener design loads. If (2) saddle washer assemblies are required, always

put the second saddle washer assembly next to the overlapping hi rib (see figure 9, below).

17.11 Follow SR2 series standing seam electric seamer manual to seam joints to a 90° bend. To prevent the possibility of panels being

blown off the building or wind-damaged, it is highly recommended that seaming be completed as soon as possible. This will ensure that

the roof assembly is adequately secured during installation.

3

/

8

" X

3

/

32

" butyl tape

sealant on top of male

leg or roof panel