Impower series, Handling instructions – Metal Sales IMPower Series User Manual

Page 5

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

4

IMPower Series

TM

HANDLING INSTRUCTIONS

Equal

lift

point

1.0 ARRIVAL ON SITE

1.1 IMPower Series panels are carefully bundled and stretch-wrapped to prevent damage during shipping. The transportation company is

responsible for delivering these components undamaged. Freight claims should be handled directly with the freight company.

1.2 When shipment is received, check each item against the bill of lading for quantity, length, transit damage, etc. If shortage or damage

is found, make sure a notation of it is made on the bill of lading and signed by the driver. It is the customer's responsibility to make any

damage claim(s).

1.3 Please notify Metal Sales of any order discrepancies within 72 hours of delivery. Otherwise, Metal Sales will conclude that the order was

completed successfully.

1.4 A panel packing list is provided for each bundle and is located within a sleeve adhered to the side wrapping. Please use this document

to check for bundle information.

1.5 IMPower Series panels will generally arrive in large, stretch-wrapped bundles on flat bed trailers. Consequently, the bundles should be

off-loaded by means of crane system or forklift.

2.0 UNLOADING WITH A FORKLIFT

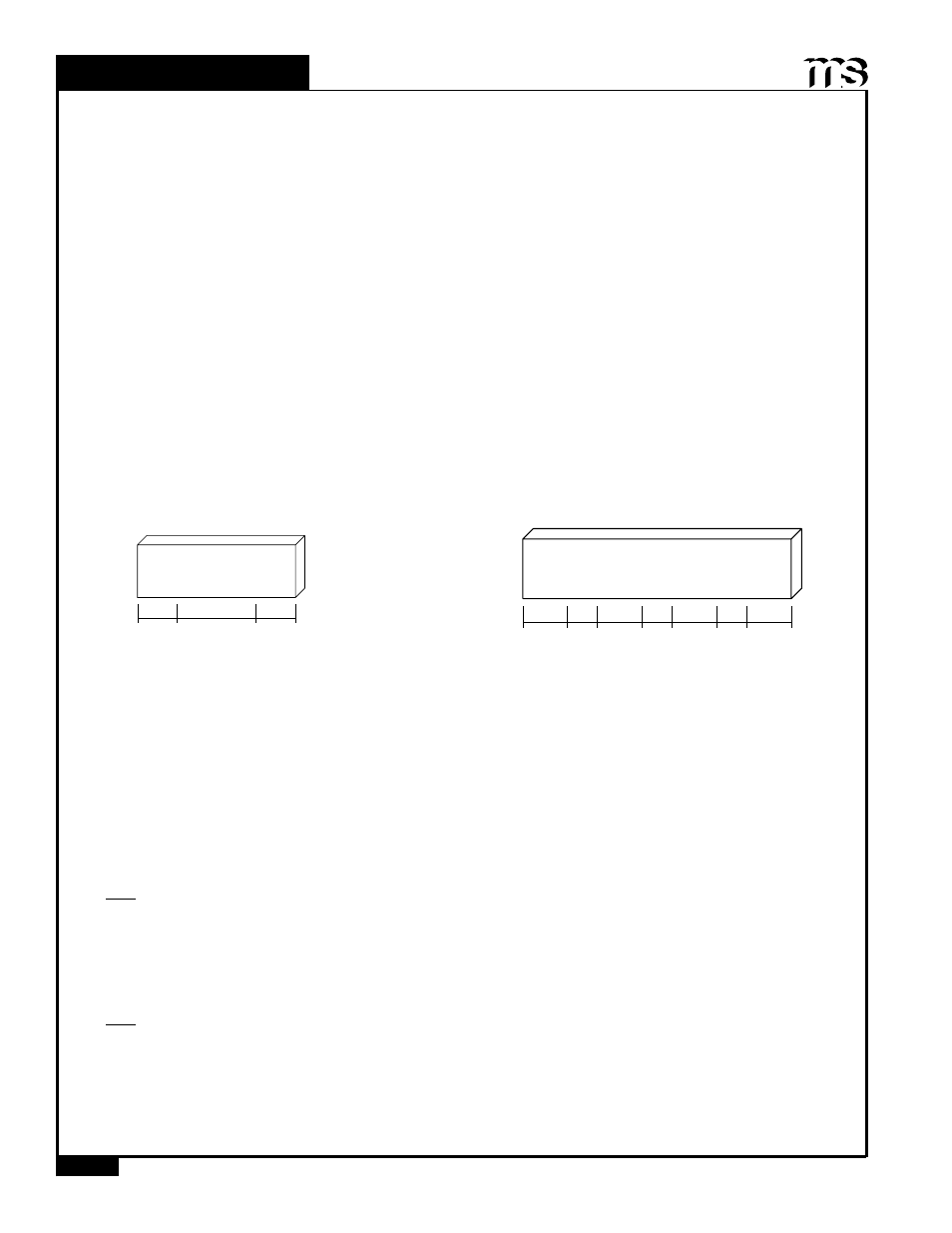

2.1 All panel bundles are reinforced with bottom sheet(s) of OSB at lifting points to prevent damage during handling. Lift bundles one at a

time with a forklift. See figure 1 (below) for recommended lifting point locations. Long-length bundles (36'-0" or longer) will have four or

more lifting points (see figure 2, below).

Note: ensure that forks are between the 3" foam stickers at the bottom of each bundle.

2.2 Do not over-engage forks when lifting a bundle as doing so may damage the bundle(s) behind it.

2.3 Assuming 48" fork blades, 6" foam blocks may be placed on the back (upright) leg of the forks to soften the contact between the forks

and the bundle.

2.4 Caution stickers are affixed to either side of each bundle as a quick on-site reference for off-loading.

Note: extreme care should be taken to avoid bumping the panels when lifting and maneuvering.

3.0 UNLOADING WITH A CRANE

3.1 Only lift one bundle at a time. When moving bundle(s) with a crane, use an appropriate combination of spreader bars, slings, and anti-

pinch boards to safely distribute the bundle's weight. When bundles are longer than 15'-0", it is suggested that a properly designed and

fabricated lifting beam / spreader bar is used.

Note: unloading with a crane is recommended for any bundles over 50'-0" long.

3.2 Anti-pinch boards should be long enough to swallow the entire width of the bundle and be placed at the top and bottom of the bundle.

Use one set (top and bottom) of anti-pinch boards per sling.

3.3 The size and quantity of the spreader bar(s) may vary depending on the length and weight of the bundle(s). Long-length bundles (36'-0"

or longer) will have four or more lifting points (see figure 2, below).

3.4 Only lift one bundle at a time.

"Standard-length" bundles (8'-0" to 36'-0")

Equal

lift

point

Equal

lift

point

8'-0"

nts

Use one forklift to lift bundles at the lift

point sections.

When handling long-length bundles, be careful not

to position your lift at the center of the bundles as

this may damage the panels. Use two forklifts (or

crane straps) to lift bundle at the lift point sections.

Figure 1

"Long-length" bundles (36'-0" or longer)

Equal

lift

point

Equal

lift

point

Equal

lift

point

8'-0"

nts

8'-0"

nts

8'-0"

nts

Figure 2