Impower series, Exposed fastened roof panel – Metal Sales IMPower Series User Manual

Page 18

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

17

IMPower Series

TM

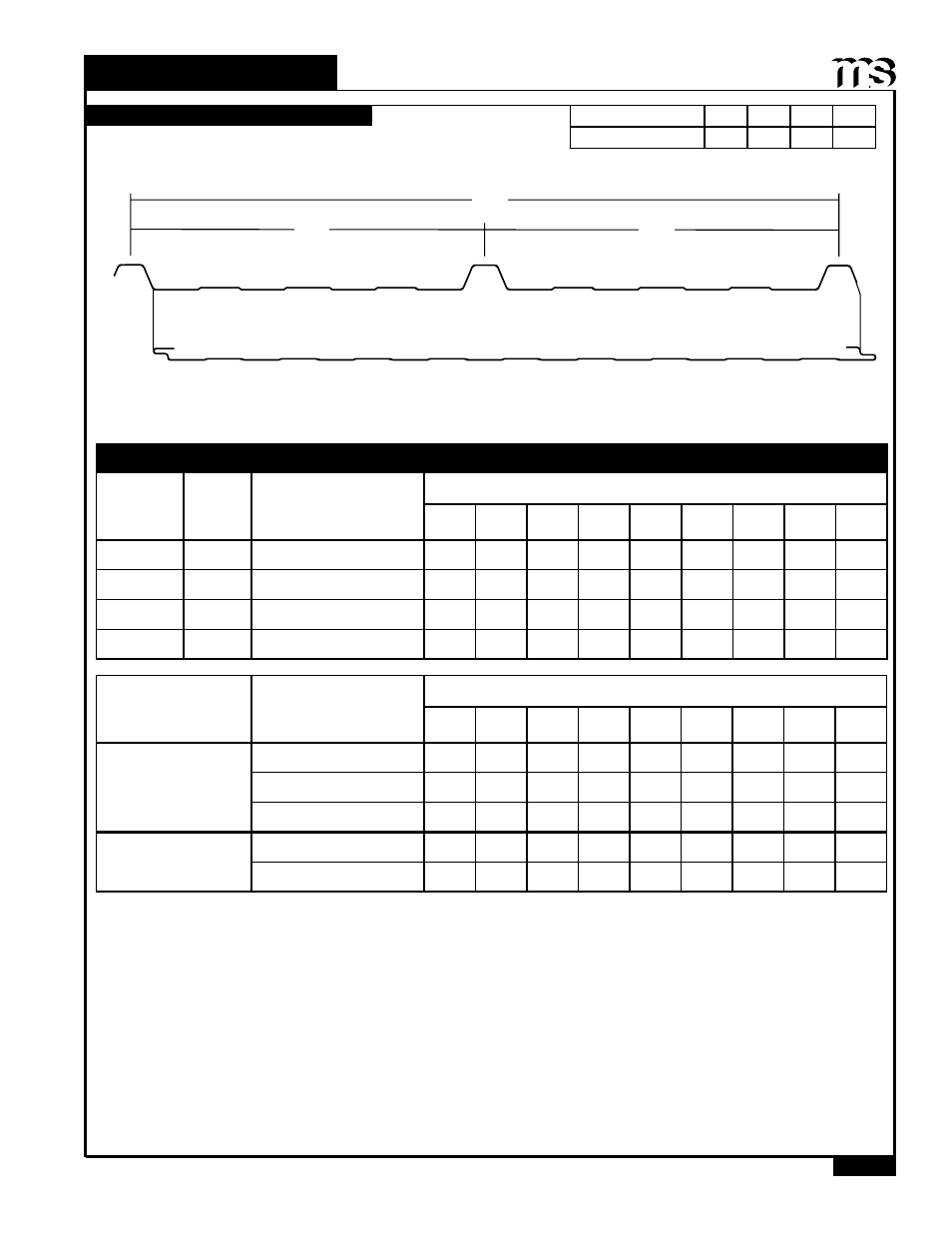

EXPOSED FASTENED ROOF PANEL

40"

HR3 High Rib Roof System

Panel Thickness 2.5"

4"

5"

6"

Insulating R-Values

26

32

41

49

Interior Side

Exterior Side

20"

20"

S

tructural

l

oad

t

able

- t

hree

or

M

ore

S

panS

p

anel

t

hickneSS

p

anel

W

eight

d

eSign

c

riteria

S

pan

(

ft

.)

2.5

3

3.5

4

4.5

5

5.5

6

7

2.5"

2.33

Panel/Deflection Limit

139

114

96

83

73

65

59

54

45

4"

2.65

Panel/Deflection Limit

191

158

134

116

102

90

81

73

61

5"

2.86

Panel/Deflection Limit

239

198

168

146

128

114

102

93

77

6"

3.12

Panel/Deflection Limit

286

238

202

175

155

138

124

112

94

f

aStening

p

attern

c

onnection

S

trength

S

pan

(

ft

.)

2.5

3

3.5

4

4.5

5

5.5

6

7

1 Fastener

20" on center

16 gauge purlins

71

59

50

44

39

35

32

29

25

12 gauge purlins

149

124

106

93

83

75

68

62

53

3/16" thick purlins

294

247

213

186

165

148

136

124

106

1 Fastener

10" on center

16 gauge purlins

105

88

76

66

59

53

48

44

38

12 gauge purlins

223

186

160

140

124

112

102

93

80

NOTES:

1. Spans shown are based on transverse load testing per ASTM E 72 and strength of fastening patterns.

2. Spans calculated with 26 gauge exterior and interior facings.

3. The lowest allowable load between panel design and connection strength must be used to determine maximum span.

4. Fastening calculated with 1/4-14 Tek 3 for 16 gauge and 12 gauge purlins. 1/4-20 Tek 5 for 3/16" thick purlins.

5. Deflection limit: L/240

6. Safety Factor = 2.5 for buckling, 3.0 for shear, 3.0 for fastening.

7. Structural capacity of purlins have not been considered.

8. Thermal effect due to temperature differentials have not been considered.

9. Consult your Metal Sales representative for project specific requirements.

10. Consult your Metal Sales representative for FM Global Loss Prevention Data Sheet 1-28 requirements.