Impower series, Sr2 roof panel installation – Metal Sales IMPower Series User Manual

Page 17

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

16

IMPower Series

TM

SR2 ROOF PANEL INSTALLATION

18.7 After preparing the upper course panel, placing the caulk, and clipping edges, set the upper course panel in place. Install SR clip

assemblies on all supports.

18.8 Once the upper panel is in place and fastened, fasten down the end-lap using the 1/4 - 14 x 7/8" stitch fastener. The fasteners should be

placed in the locations shown on the shop drawings. The fastener should be placed approximately 1" from the end of the upper course

panel exterior facing so that it penetrates the caulking and achieves full compression of the facings at the last row of caulking.

18.9 Remove all metal chips and filings from the drilling of pilot holes and fastening of the panels immediately after installation. These filings will

rust and corrode the panel surface.

18.10 Proceed to the next panel and repeat steps 18.2 through 18.9.

18.11 After all panels are installed, fasten the eave, rake, and peak trims, respectively. The trim should be fastened as shown on the shop

drawings.

19.0 PEAK TRIM INSTALLATION PROCEDURE

19.1 Fasten the roof panels at the ridge as shown on the shop drawings.

19.2 Temporarily set the Peak trim in place to determine the location of the caulking and closure strips. Run a line or snap a chalk line along the

length of the Peak trim for proper placement of the caulking and closure strips.

19.3 Apply butyl tape onto the panel as shown on shop drawings in preparation for the closure strip. All surfaces to receive caulk and closure

strips.

19.4 Seat the closure strip firmly onto the butyl tape to ensure a continuous seal. If voids exist, add additional butyl sealant and reseat the

closure correctly.

19.5 Place butyl tape onto the closure strip and place the Peak trim as shown on shop drawings. Fasten the apex trim at each hi rib with a 1/4-

14 x 7/8" stitch fastener. At the end of the Peak trim, place two beads of the caulk or tape sealant 2" from the end and overlap the next

Peak trim approximately 4". Fasten the overlaps down with 1/4 - 14 x 7/8" stitch fasteners as required.

19.6 Immediately remove any metal chips or filings from the screws or sheet metal fabrication as they will rust and corrode the panel surface.

18.5 If the ridge cap detail is to be used, place the inside ridge cap and caulking bead as shown on the shop drawings. The caulking bead

should be married to the bead in the overlapping rib as the panels are set in place.

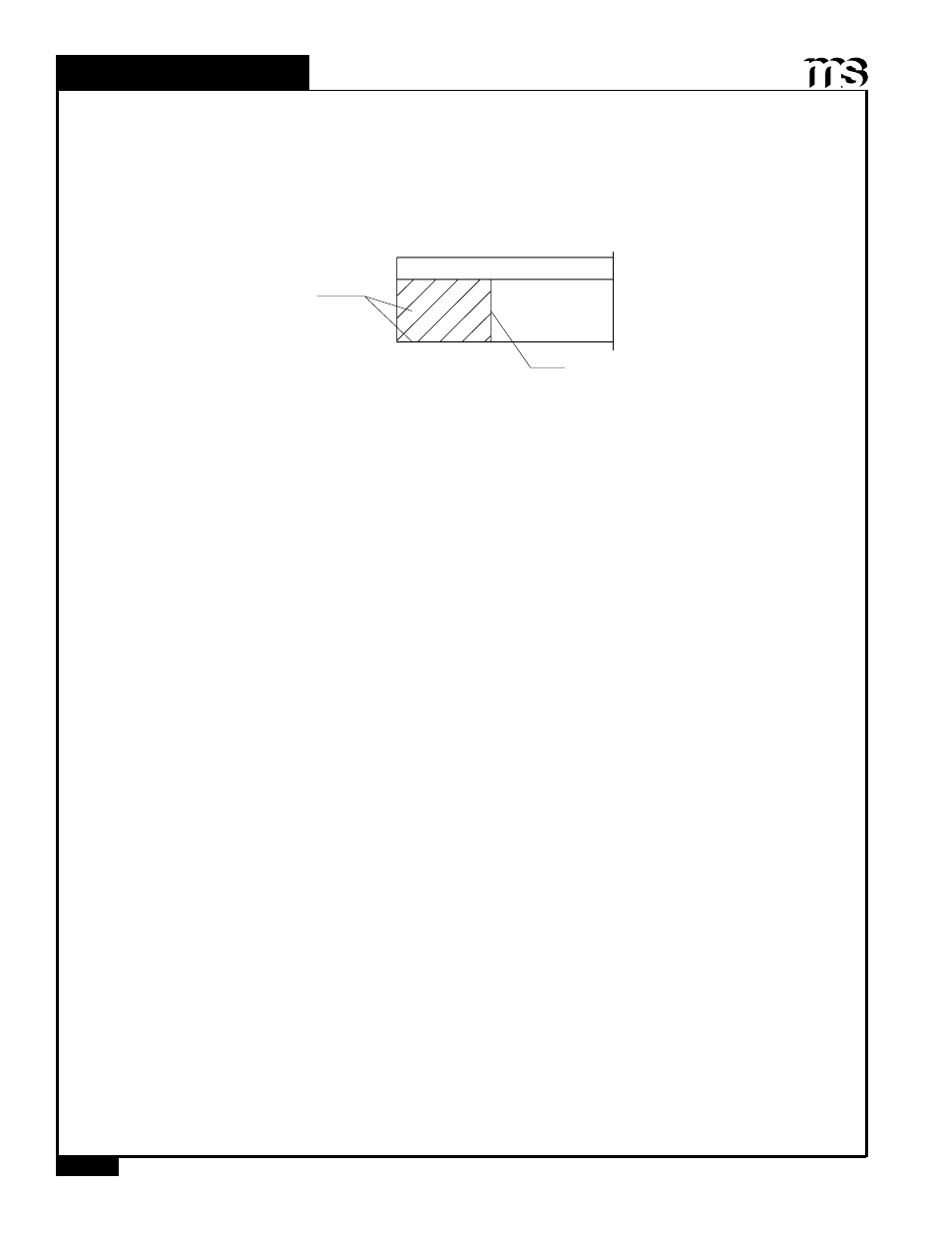

18.6 All Weather Insulated Panels that incorporate end laps will arrive at the job site with the foam and liner face in place. The liner face of the

upper course panel will have a factory saw cut 3" to 6" from the end of the panel (see figure 11, below). Remove the metal and foam at the

end of the panel. Carefully remove any foam that remains on the metal skin to ensure a positive air and water infiltration seal.

Figure 11

Field-remove foam

and liner skin

Factory cut if required