Impower series, Wall panel installation – Metal Sales IMPower Series User Manual

Page 10

© Metal Sales Manufacturing Corporation / Subject to change without notice 1/14

9

IMPower Series

TM

14.2 Place bottom end of panel on base and tilt to vertical position. Longer panels may require the use of a rope hoist or a panel lifting device

such as a Wood's Powr-Grip.

14.3 After drilling or cutting panels, always remove metal chips that have fallen on the flashing or panels to preclude later damage.

14.4 Position starter panel in place and through-fasten to the support steel with #14 through fastener(s) at each girt line. Position the #14

through fastener(s) close enough to the panel edge such that they are covered by the outside corner trim. Position the end or other

starter panel in place and through-fasten to the support steel. Caulk and fasten the outside corner trim to the wall panels with color-

matched screws or pop rivets at 12" o.c. (unless noted otherwise on the project shop drawings) to complete the corner installation.

Note: if installing the (optional) inside corner trim, fasten at 12" o.c. with #10 x 3/4" Pancake head fasteners between girts (unless noted

otherwise on the project shop drawings).

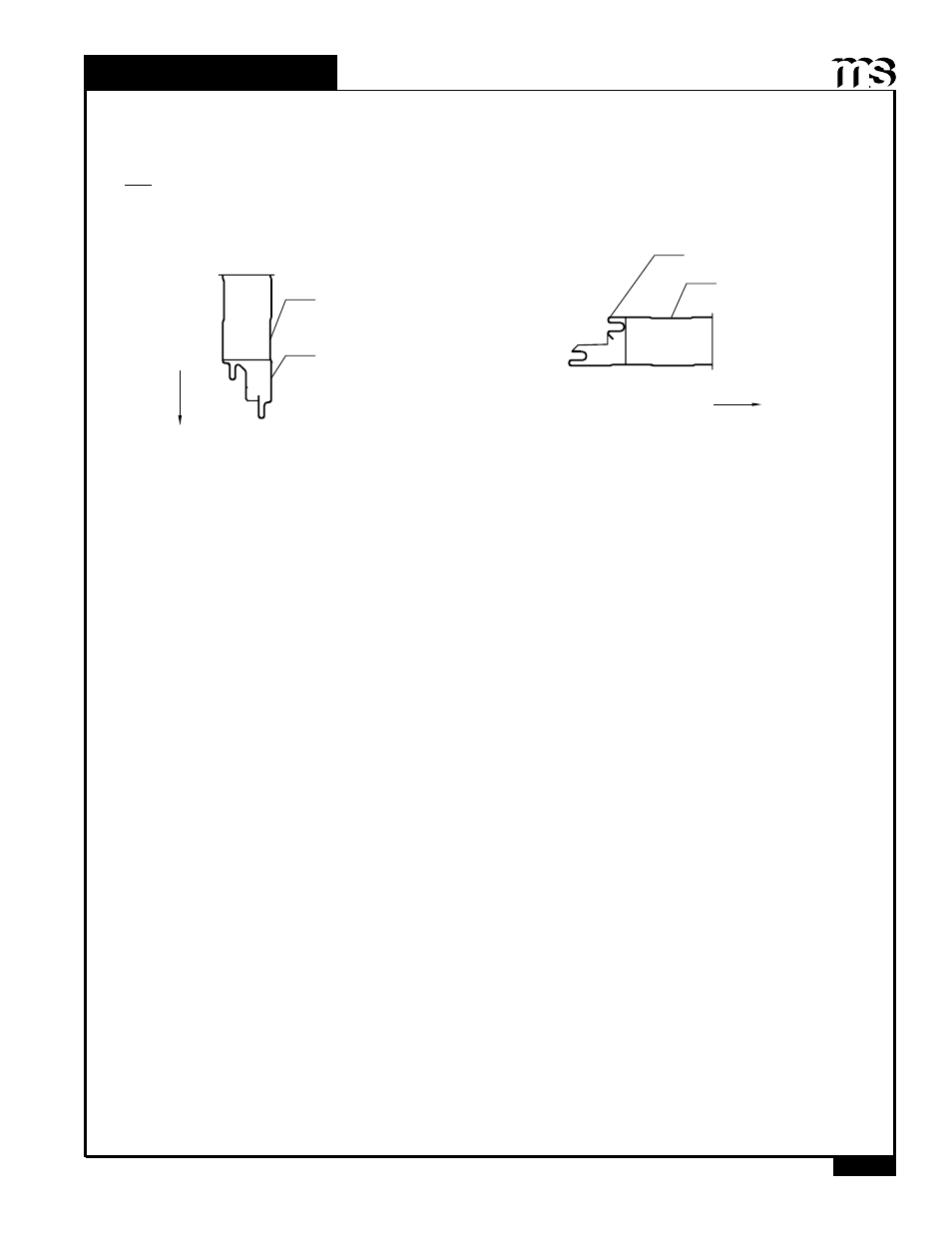

14.0 CORNER INSTALLATION

14.1 Panels are installed from left to right when viewed from the exterior. Starter and end panels should be field cut as shown (see figure 6,

below).

Note: Panels may be installed from right to left by turning the panel over. Remember that the female edge of the wall panel is always the

leading edge when using the hidden fasteners.

End wall panel

Field cut male leg

Installation Direction

Field cut female leg

Starter wall panel

Installation Direction

Figure 6

15.0 WALL PANEL INSTALLATION

15.1 Place bottom end of panel on base and tilt to vertical position. Longer panels may require the use of a rope hoist or a panel lifting device

such as a Wood's Powr-Grip.

15.2 Slide panel firmly into groove of the preceding panel using firm, gradual pressure to draw panels together. Do not pound into place. Do

not use localized forces which may damage panels. To ensure a consistent joint modulation, spacers (5/32" max.) may be used at the

exterior side as panel are being engaged (non-cold storage applications only). Plumb and square each panel before installing fasteners.

Note: Prior to installation, panels may need to be placed in a covered location to prevent excessive thermal bow which may hinder panel

engagement.

15.3 Hidden clip style wall panels are attached to support steel using WC-01 clip and fastener assemblies.

15.4 To install fastener, pre-drill (as required) using the appropriate drill size. Insert fastener through clip and tighten down until clip and

fastener assembly are snug. Fastener requirements are based on given design loads. Panels are to be fastened per shop drawing

details and calculated fastener schedule provided on shop drawing projects. Use a 600 rpm electric screw gun to drive fasteners. Do

not use impact tools. Do not over-tighten.

15.5 Trim(s) shown in the shop drawings should be used where panels terminate such as head, sill, base, butt, etc. conditions. Cover

exposed edges as soon as possible.

Note: Use suction lifters, as needed, to maximize safety and minimize undue manual handling.

WALL PANEL INSTALLATION