5 technical data, 1 technical data of the mc-pnd communication card, Technical data – Lenze PROFINET Controller-based Automation User Manual

Page 18: Technical data of the mc-pnd communication card, 5technical data

5

Technical data

5.1

Technical data of the MC-PND communication card

18

Lenze · Controller-based Automation · PROFINET® Communication Manual · DMS 1.2 EN · 04/2014 · TD17

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5

Technical data

5.1

Technical data of the MC-PND communication card

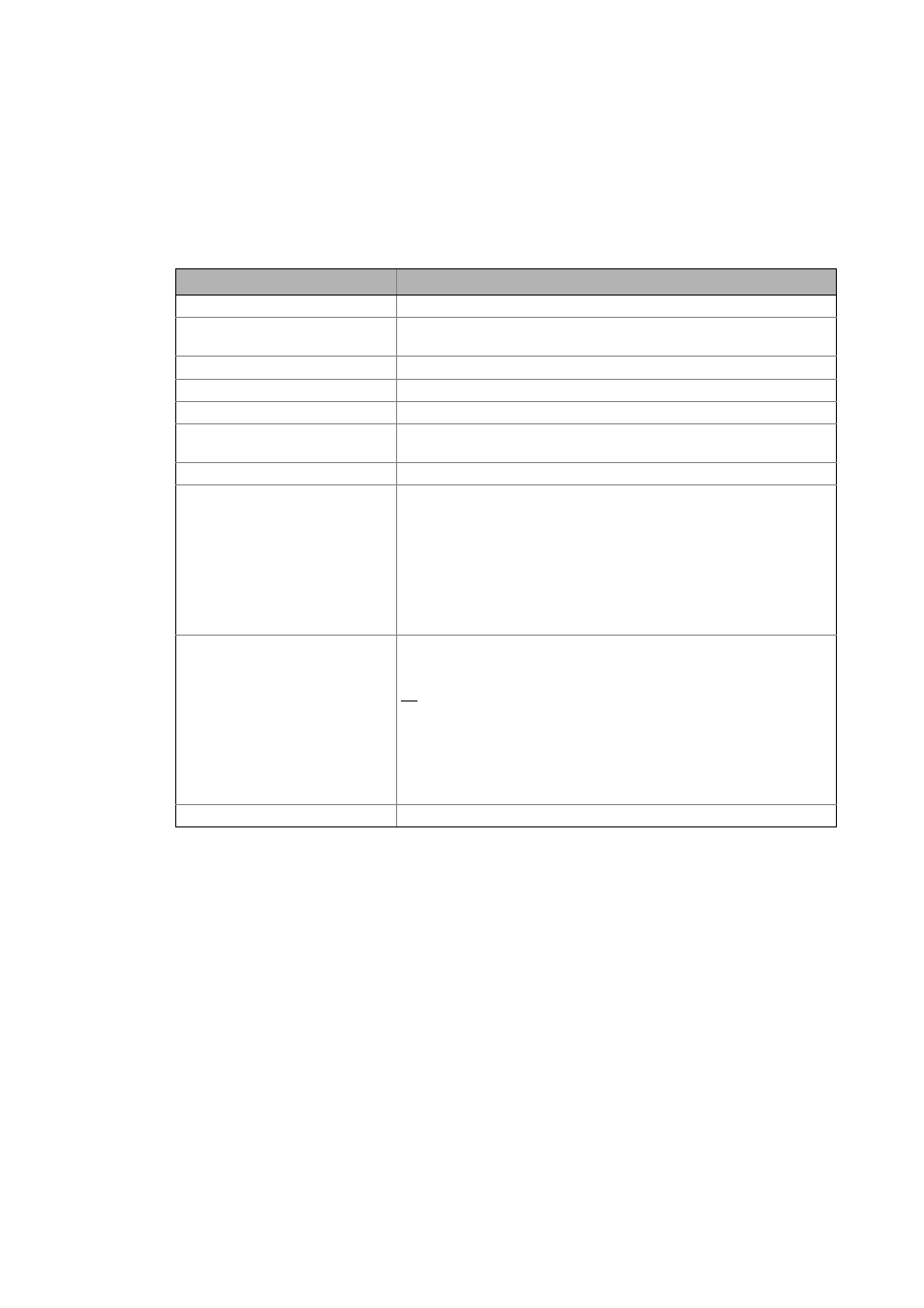

Area

Values

Communication profile

PROFINET

Communication medium / cable

type

S/FTP (Screened Foiled Twisted Pair, ISO/IEC 11801 or EN 50173), CAT5e

Standard Ethernet (acc. to IEEE 802.3), 100Base-TX (Fast Ethernet)

Network topology

Line, star and tree

Type within the network

PROFINET I/O device (slave)

Max. cable length

100 m between two stations

I/O data (PDO data)

Max. total of 8 PDOs (1024 bytes),

independent of their direction (In/Out)

Communication type

PROFINET I/O, cyclic

Functions

• Transmission of cyclic process data

• Context Management via CL-RPC (Connectionless Remote Procedure

Call)

The Context Management Protocol is used for:

• Connection establishment and termination

• Request for resources

• Exchange of configuration and diagnostic information

• Upload/Download of data records

• Setpoint/actual value comparison of the PROFINET configuration

Special features in the

Lenze automation system

Configuration in the »PLC Designer«:

• No submodules

• Only one device instance is supported.

No support of ...

• acyclic read and write requests

• DCP (Discovery and basic Configuration Protocol)

• RTP (Real-Time Transport Protocol) over UDP (User Datagram Protocol)

• Multicast communication

• Process-/diagnostics alarms

• Generic diagnostics, channel diagnostics

Minimum cycle time

4 ms