Koolance ERM-3K3UC-R User Manual

Page 15

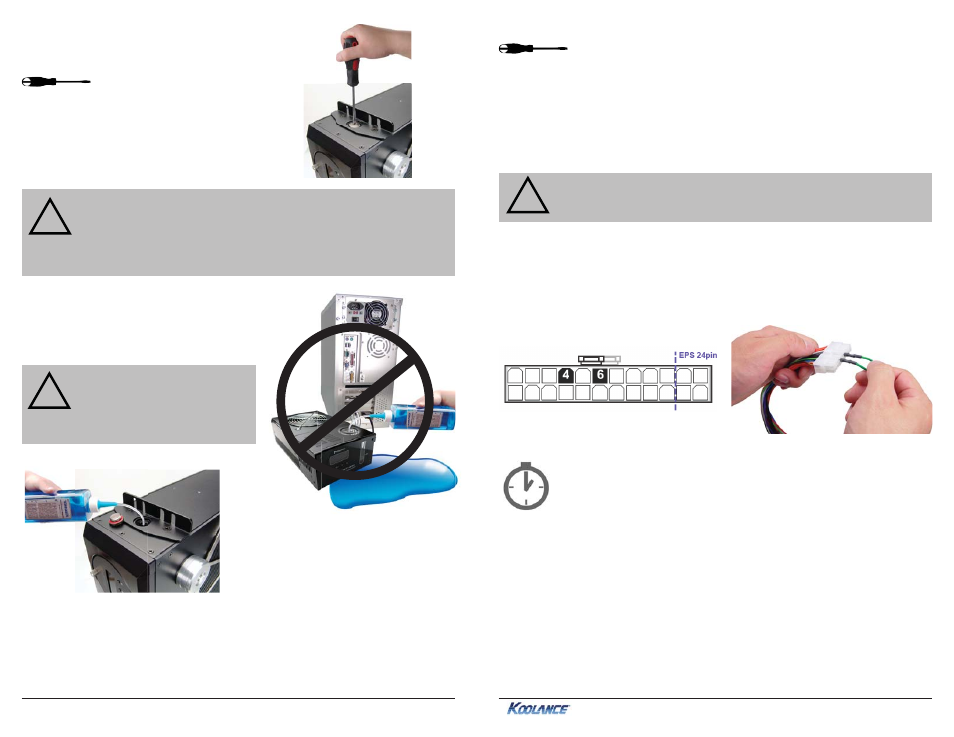

22

23

User Manual

Slowly fill the system. To maintain the

product warranty, use only Koolance

approved coolant.

Many alternative

liquids and additives can cause perma-

nent damage to the cooling unit (through

chemical reaction, corrosion, biological growth, thermal expansion, viscosity,

etc.).

In the vertical orientation, a harmless waterfall effect can be created by intentionally

under-filling the reservoir. When oriented in a horizontal position, more coolant is

needed for the pump to properly circulate coolant throughout the system.

Filling & Maintenance

Once all the water blocks have

been connected, the system can

be filled with coolant. The fill port is located on top of

the reservoir. Remove the large slot-headed screw

(with a screwdriver or large coin).

Testing & Filling

WARNING

:

Most coolants are electrically conductive. Use caution

when filling the system, and keep all liquids away from electronics and

power cables. In case of emergency during installation, immediately

unplug the primary AC power cable. Dry the system thoroughly before

proceeding.

!

CAUTION

:

When filling, the

cooling system’s fill port should

be higher than all other liquid

components to avoid spillage.

!

When empty, the cooling unit’s fill port should be

placed above all other water blocks when adding

liquid. Otherwise, coolant can be forced out the fill

port instead of into the hoses.

If your pump has a speed control option, set it to the lowest level during

this time. Allow the pump to run until the liquid noise subsides.

During this process, cooling systems often need to be tilted gently

to allow air to escape from the pump and radiator. Until the pump

is “burped” in this manner, it can cavitate and there will be no

circulation.

(This does NOT indicate a problem with the pump.)

The reservoir level will decrease during this procedure. Remove the

fill port cap and add more liquid when needed. If you frequently hear

this rushing noise in the future, it usually indicates the need for more

coolant.

Replace the fill port on the reservoir. Do not overtighten the fill port.

The cooling system should be powered on to assist in the filling process. This also

allows you to check hose connections and make sure there are no tubing folds,

leaks, or blockages. If cooling a computer, this can be done without powering on

other hardware for extra safety (see below).

CAUTION

:

Jumping the incorrect ATX power supply pins can cause

permanent damage to the power supply.

!

Make sure the AC power cord is attached to the power supply. If the power supply

has a rear switch, it must be set to the ON (-) position. Using the included green

Jumper Wire, insert the metal prongs into the fourth and sixth holes on the 20-24

pin ATX motherboard power supply plug (usually green and a black ground wire;

See diagram

).

That’s it! Replace the ATX motherboard connection and boot-up the computer.