Interfaces – JUMO 706560 LOGOSCREEN es Data Sheet User Manual

Page 6

JUMO GmbH & Co. KG • 36035 Fulda, Germany

Data Sheet 70.6560

Page 6/12

2009-12-14/00415638

Interfaces

k Setup interface

(fitted as standard)

k RS232 interface

(fitted as standard)

k RS422/485 interface

(extra code)

k Ethernet interface

(extra code)

k LON interface

(extra code)

k PROFIBUS-DP interface

(extra code)

Setup interface

The setup interface is used together with

the PC interface cable (including the TTL/

RS232 converter and adapter) for opera-

tion of the PC setup program (see Page 5).

The paperless recorder has setup interfac-

es (connected in parallel) on both the front

and back panels. They cannot both be

used at the same time.

RS232 interface

RS422/485 interface

The current process data, as well as specif-

ic instrument data, can be read out via the

RS232 or RS422/RS485 interfaces.

The data that are stored in the internal

memory can also be read out in conjunc-

tion with the PC evaluation software

PCA3000 and the PCA communications

software (PCC).

Normally, the instrument is supplied with a

RS232 interface which allows for a lead

length of maximum 15 meters. The RS422/

RS485 interface permits a lead length of

1.2 km.

Connection is by a 9-pin SUB-D connector

at the back of the instrument. Modbus and

Jbus protocols are available, and the trans-

mission mode used is RTU (Remote Termi-

nal Unit).

Ethernet interface

The Ethernet interface can be used in local

networks for communication between the

paperless recorder and the PC setup pro-

gram or the PCA communications soft-

ware. The IP address is given a fixed

setting through configuration on the instru-

ment or in the PC setup program.

When using the Ethernet interface, care

must be taken to ensure that only one client

at a time is permitted to access the instru-

ment (server).

Transmission protocol: TCP/IP

Network type: 10BaseT

PROFIBUS-DP interface

The paperless recorder can be integrated

into a fieldbus system according to the

PROFIBUS-DP standard, via the PROFI-

BUS-DP interface. This PROFIBUS variant

is particularly suitable for the communica-

tion between automation systems and dis-

tributed peripheral devices at the field

level.

Data transmission takes place serially ac-

cording to the RS485 standard, at a maxi-

mum of 12Mbit/sec.

Using the project design tool that is includ-

ed in the delivery (GSD generator; GSD =

Device Base Data), an application-specific

GSD file is created, which is used to inte-

grate the paperless recorder into the field-

bus system.

Up to 36 channels can be read in via the

PROFIBUS.

LON interface

The LON interface is used to expand the

measurement channels (channels 13 — 36)

through modules from the JUMO mTRON

automation system.

External CompactFlash

memory card (CF)

The external CompactFlash memory card

is used to transfer the data from the internal

memory to the PC. Configuration data can

be created on the PC and then transferred

to the paperless recorder by means of the

memory card.

On the PC side, data on the card is ac-

cessed with the help of a CompactFlash

reader/writer.

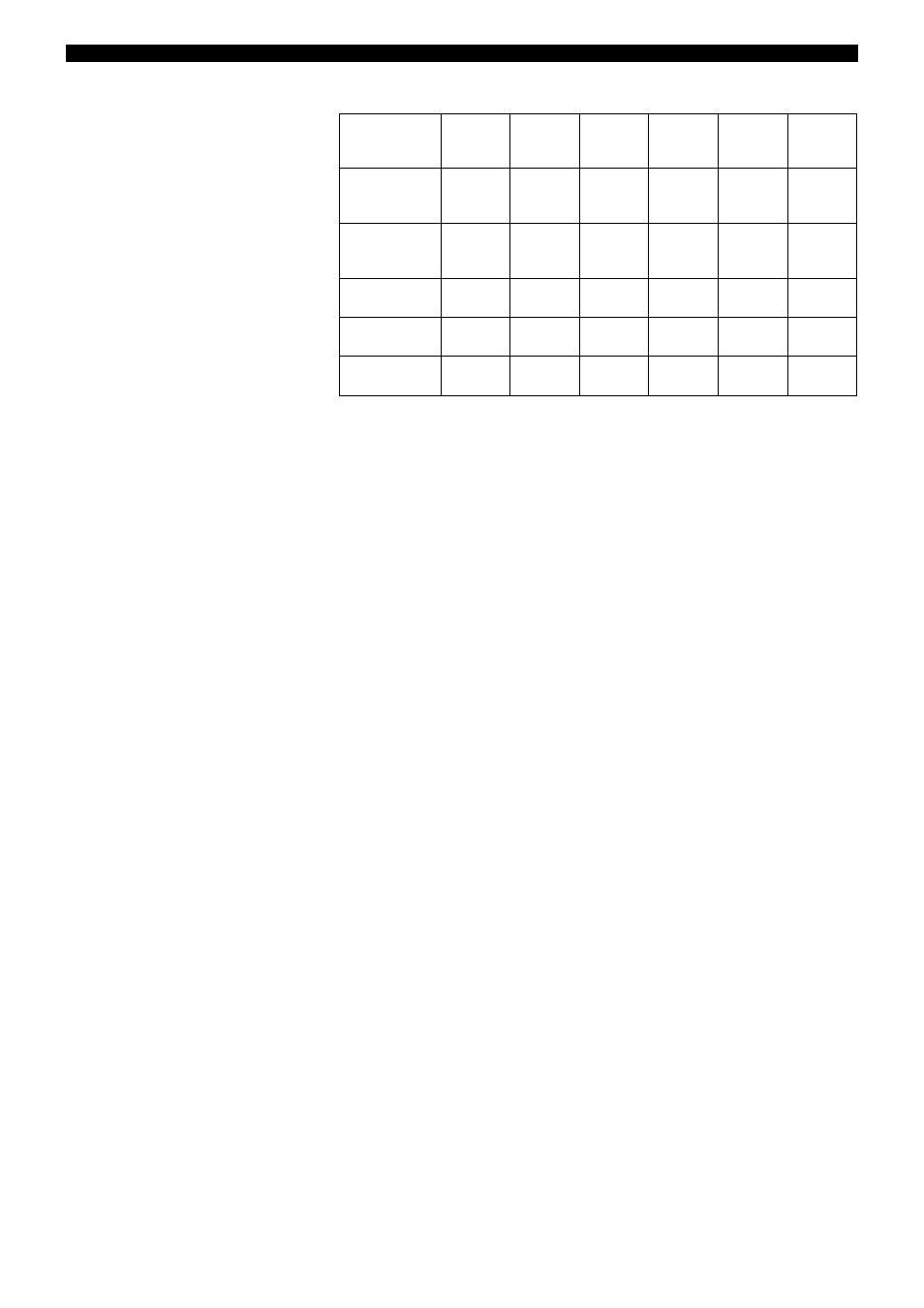

Setup

interface

RS232

RS422

RS485

Ethernet

PROFI-

BUS-

DP

LON

External

CF card

Read/write

measurements

(present data)

yes

yes

yes

yes

yes

no

Read

measurements

(stored data)

yes

yes

yes

no

no

yes

Read/write

configuration

yes

yes

yes

no

no

yes

Write

user list

yes

yes

yes

no

no

yes

Read

screen memory

yes

yes

yes

no

no

no