Incra right angle fixture - assembly and use, Step 1. attach faceplate to base, Fig. 8 – INCRA Jig Fence System User Manual

Page 4: Fig. 8a, Fig. 9, Step 2. attach wooden runners, Fig. 10, Fig. 11, Right angle fixture operation

4

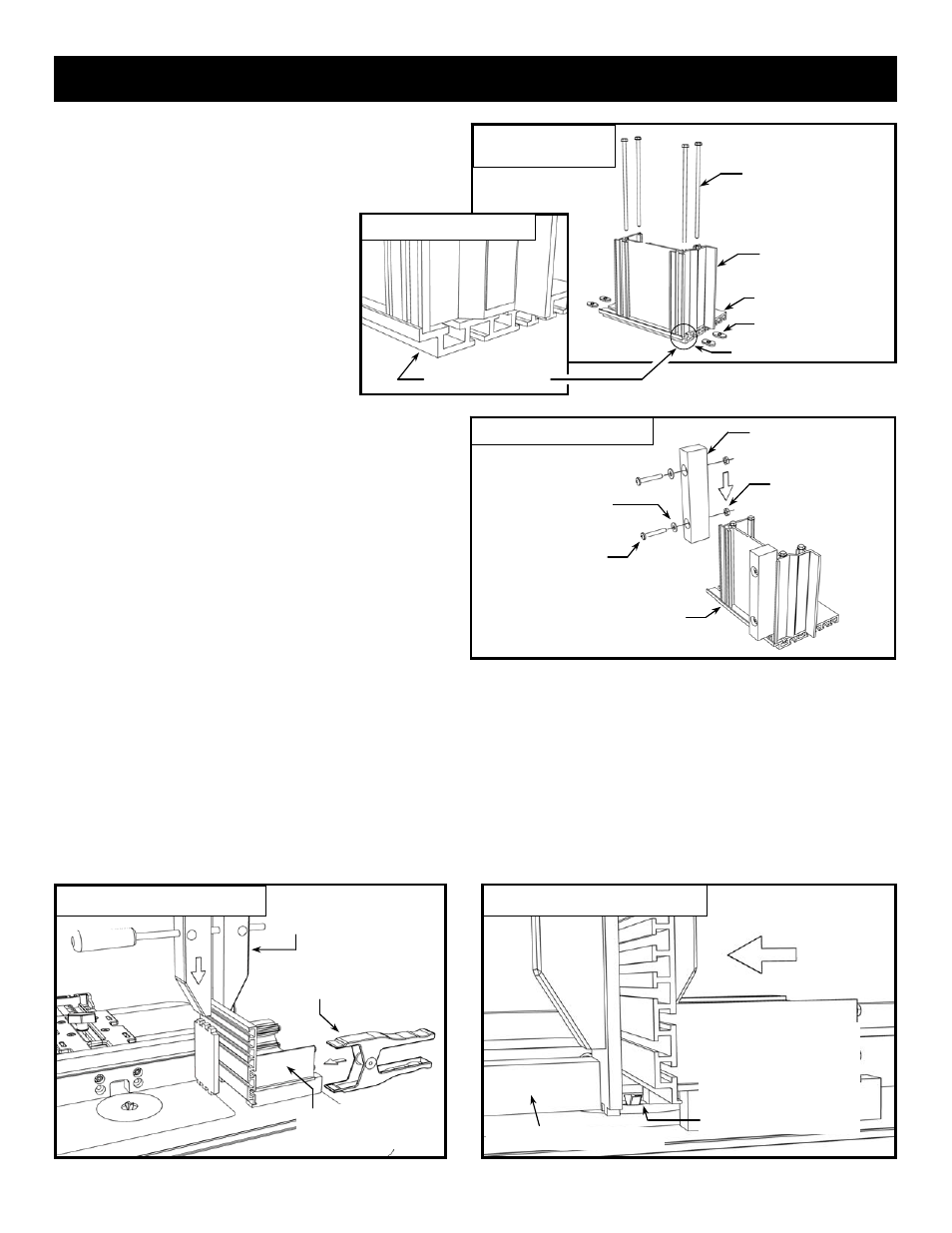

Step 1. Attach faceplate to base.

Attach the INCRA Right Angle Fixture faceplate to the

INCRA Right Angle Fixture base using the (4) supplied

10-32 x 5 1/2” hex bolts and rectangular

nuts. Insert the bolts through the four

holes in the base and loosely attach the

(4) rectangular nuts. Now slide the T-slots

on the back of the faceplate over the

rectangular nuts, Fig. 8. Make sure the

two surfaces marked with an “x” in Fig. 8A

are aligned flush, then securely tighten the

hex bolts.

Fig. 8

Assemble Right Angle Fixture

10-32 x 5 1/2” hex bolts (4)

10-32 rectangular nuts (4)

Right angle fixture faceplate

Right angle fixture base

Fig. 8A

Faceplate alignment

x

x

Align surfaces marked “x”

INCRA Right Angle Fixture - Assembly and Use

10-32 hex nut (4)

Fig. 9

Attach wooden runners

Wooden runner (2)

10-32 x 1 1/4”

Phillips screw (4)

#10 washer (4)

Step 2. Attach wooden runners.

Attach the two wooden runners to the bottom of your

Right Angle Fixture base using the (4) 10-32 x 1 1/4”

Phillips screws, washers and hex nuts as shown in

Fig 9. Each runner should extend about 1/2” beyond

the rear of the base.

Wooden stop block clamped to fence

Fig. 10

Using the Right Angle Fixture

Fig. 11

Avoid contacting wooden runners

Avoid making contact between the

wooden runners and the router bit by

clamping a wooden stop block to the

outfeed side of the fence to stop the

forward travel of the Right Angle

Fixture

Second: Immobilize with spring

clamp (acts like a “third hand”)

Right Angle Fixture operation.

Before clamping a work piece to your Right Angle Fixture,

always press the fixture against your fence, then

immobilize by clamping it to the table with a spring clamp,

Fig. 10. When positioning the work piece against the

faceplate, make sure that the edges of the boards are

against the fence and the ends are contacting the table

surface, then clamp in place using a wooden handscrew

clamp.

CAUTION: Do not allow any part of your

hands to hang below the aluminum body of

the Right Angle Fixture. Always keep hands

well away from the bit.

To avoid contacting the wooden runners with the router bit,

clamp a wooden stop block to the outfeed end of the fence

to stop the forward travel before contact, Fig. 11.

T-slot on bottom of Right

Angle Fixture (4)

See detail in Fig. 8A

First: Push Right Angle

Fixture against the fence

Third: Position stock against fence and

clamp with a wooden jaw clamp