Step 4. assemble and attach stop positioner, Fig. 4, Using the stop positioner – INCRA Jig Fence System User Manual

Page 3: Fig. 5, Fig. 6, User made sub fences, Fig. 7, Fig. 7a

3

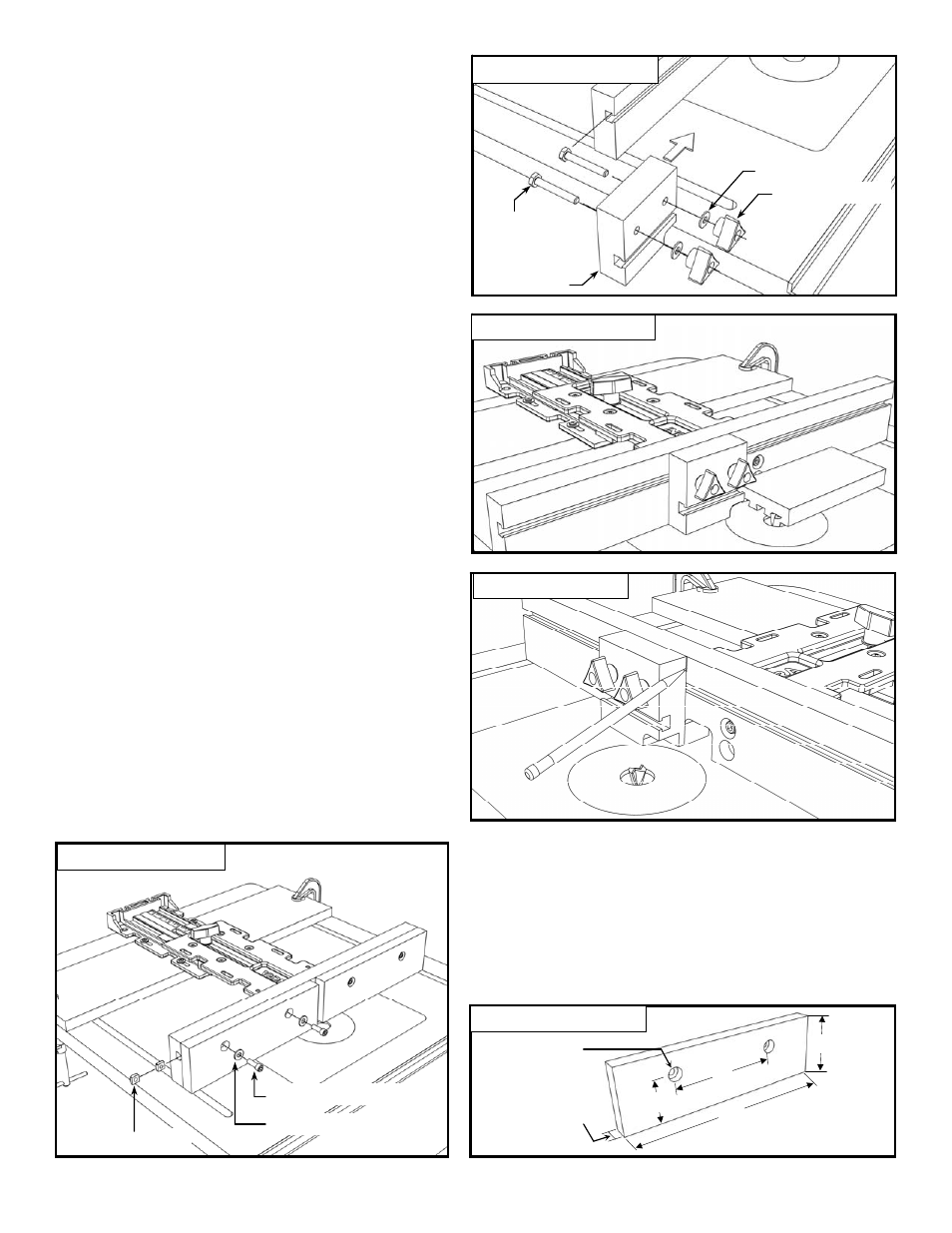

Step 4. Assemble and attach stop

positioner.

To assemble the stop positioner, insert the (2) 1/4-20 x

1 3/4” hex bolts from hardware pack D-03 through the

holes on the stop. Add the two washers and loosely

attach the 1/4-20 thumb knobs. Now slide the hex bolt

heads into the T-slot on the outfeed end of the INCRA

Fence, Fig. 4. Position the stop as needed, and tighten

the thumb knobs before use.

Fig. 4

Attach stop positioner

1/4” flat washer (2)

1/4-20 thumb knob (2)

1/4-20 x 1 3/4” hex

bolt (2)

Stop positioner

Using the stop positioner.

Use the stop positioner to limit the length of cuts made

with your INCRA Fence System. The cutaway notch

permits the stop to be positioned safely inside your

cutter’s diameter for applications such as dovetail pin

cuts shown in Fig 5.

TIP:

The un-notched end of the stop can also be used

for the stopping surface by simply rotating the stop 180

degrees before attaching it to the fence’s T-slot.

Fig. 5

Using the stop positioner

Fig. 6

Mark stop position

TIP: Marking the stop’s position before

making fine adjustments.

When making fine adjustments relative to an initial stop

position, place a reference mark on the front face of the

fence along the leading edge of the stop positioner, Fig

6. Now, when you loosen the thumb knobs to reposition

the stop, you an easily gauge how much you have

moved the positioner. After use, the pencil mark is

easily wiped off the hard laminate surface on the front

face of the fence.

User made sub fences.

User made sub fences for variable gap width and zero

clearance applications can be attached to the T-slot on the

front of the fence. Just cut to size, drill and counter bore

the MDF or plywood fences, using the dimensions shown in

Fig 7A. You can attach sub fences up to 3/4” thick with the

1/4-20 x 3/4” socket head cap screws, washers and square

nuts supplied in hardware pack D-04, Fig. 7A.

Fig. 7

User made sub fences

1/4-20 x 3/4” socket head screw (4)

1/4-20 square nut (4)

1/4” washer (4)

6”

10”

5”

2”

3/4”

5/16” diameter through hole

with 5/8” diameter by 3/8”

deep counter bore (2)

Fig. 7A

Sub fence dimensions