Applications/joint maker, Setting the router bit depth of cut for box joints, Centering the router bit on your workpiece – INCRA Ultra Lite User Manual

Page 4

6

Joint making represents one of the most exciting applications for

your new Incra Jig Ultra Lite. Just by applying a little technique to

the accuracy of your Incra Jig, you’ll soon be able to add joinery for

box and drawer making to your list of shop skills. The two templates

included with the basic set will allow you to produce equally spaced

3

⁄

8

" box joints and equally spaced

1

⁄

2

" half blind dovetails.

There are three important operations that must take place each

time you use your Incra Jig for joint making at the router table:

1. Setting the router bit depth of cut

2. Centering the bit on your workpiece and installing

the template

3. Cutting the joint

We’ll begin with a look at the first two operations. These are

simple setup procedures with which you will want to become

familiar. They will be used every time you prepare to cut a joint at

your router table. Beginning on page 10, we will apply these two

setup operations in a step-by-step description for cutting box joints

and half blind dovetails.

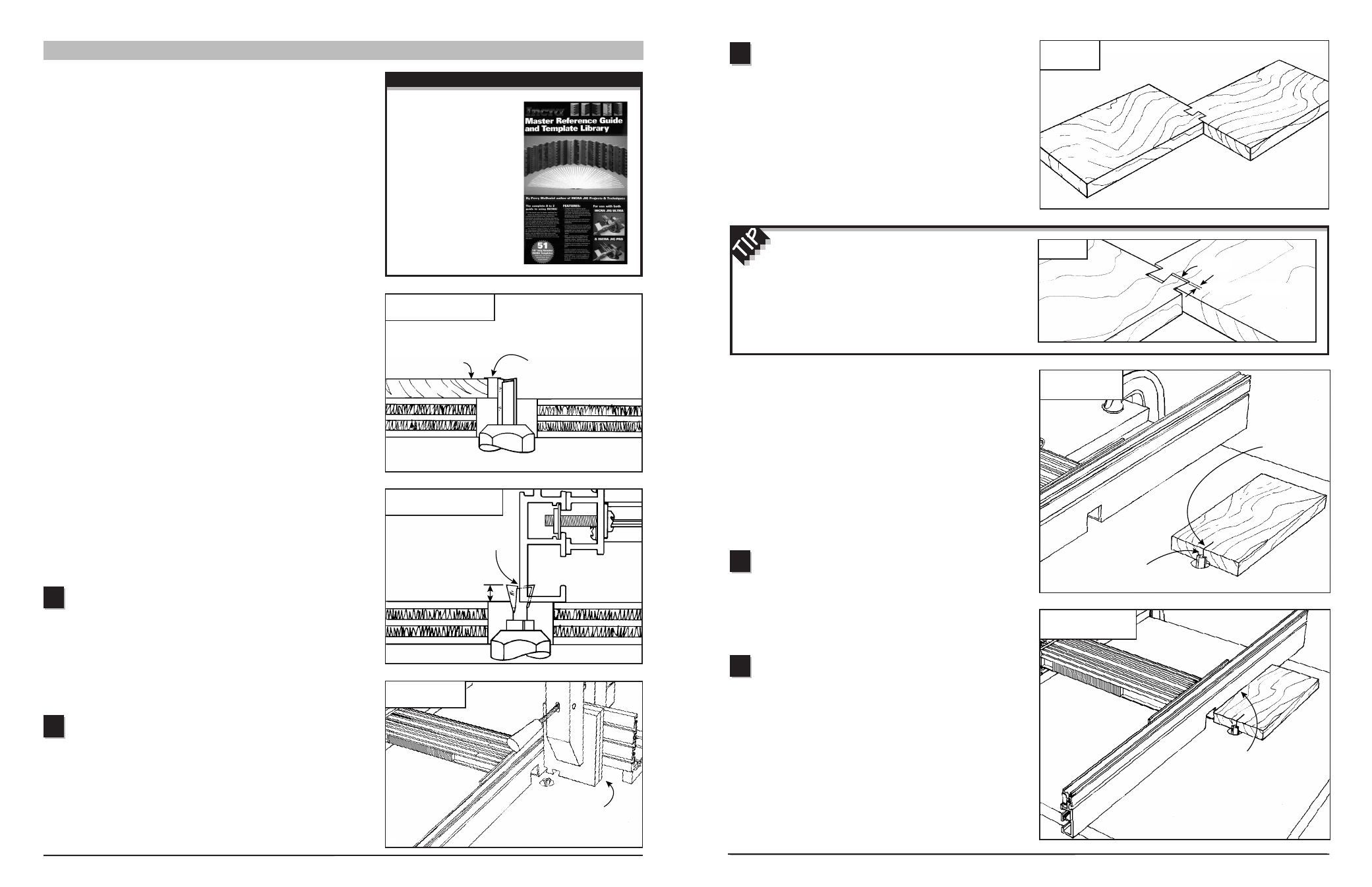

Setting the Router Bit Depth of

Cut for Box Joints

After installing the appropriate diameter straight bit for the template

pattern you have selected, (a

3

⁄

8

" straight bit is required for the

Box1 template included with your Ultra Lite System) simply raise or

lower the bit in your router table to set the depth of cut at slightly

greater than the thickness of the stock you will be cutting. See

Fig. 12. Just remember, router bit manufacturers suggest that you

not cut any deeper than the diameter of the bit in any single pass.

APPLICATIONS/JOINT MAKER

FIG. 12

Depth of cut for box joints

For even more variety,

including through and

double dovetail

techniques, the optional

Incra Master Reference

Guide and Template

Library

contains a large

selection of new joinery

templates. For pricing

and ordering information,

see page 16.

FIG. 13

Set approximate depth of cut

Setting the Router Bit Depth of Cut

for Dovetail Joints

As with any half blind dovetail jig, the depth of cut of your

dovetail bit will determine how well the finished joint fits. Just a

little practice using the following steps will ensure that your

dovetail joints will always have a perfect fit.

Set the approximate depth of cut

Install the dovetail bit that corresponds to the template you

are using. (A

1

⁄

2

", 14° dovetail bit is required for the DOV1

template included with your Ultra Lite System.) Raise or lower

the bit to the approximate depth of cut listed under the diagram of

your template pattern. (

1

⁄

4

" for the DOV1 template, see diagram

on page 11.) Position your fence as shown in Fig. 13 so that

about half of the bit is inside the fence notch. Now slide the

1

⁄

32

"

scale on your Incra Jig to read 0" under the hairline cursor.

Make the test cuts

Clamp two pieces of square cut stock to your Right Angle

Fixture. You are now going to make two dovetail cuts on the

boards as shown in Fig. 14. The spacing between these two

cuts is listed under the diagram of your selected joint pattern.

For example; if you were setting the depth of cut for the DOV1

pattern included with the Ultra Lite System, the diagram shows:

Spacing to set depth of cut =

7

⁄

8

". Using the

1

⁄

32

" scale set in

Step 1, you would make a cut at the 0" setting, then move to

7

⁄

8

"

to make the second cut.

1

2

Raise or lower bit to

slightly greater than

the thickness of

your stock

Board to be joined

First: Set bit height

to recommended

approximate depth of cut

More Joinery Templates

FIG. 14

Make the test cuts

Second: Position the fence

so that about half of the bit

is inside the fence notch

Third: Slide the

1

/

32

" scale

to read 0" under the cursor

First: Clamp two

boards to Right Angle

Fixture

Second: Make

a cut at the 0"

setting

Third: Move fence

back to dimension listed

under diagram of your

joint pattern (

7

/

8

" for

DOV1 pattern) and

make second

cut

Centering the Router Bit on your

Workpiece

After setting your router bit depth of cut, you need to

position your Incra Jig and install the joinery template so

that all the cuts are made in the right places on your

wood. This is accomplished through a setup operation

called “centering”. Centering locates your Incra Jig so

that the router bit is aligned with the center of the stock

width you wish to use. Once you find the center, install

the selected template and you’ll be ready to cut a

perfect joint. The simple steps to follow should always

be used when setting up your Incra Jig for joint making.

Align board with bit

Begin by cutting a piece of

3

⁄

4

" thick stock to the

same width as the boards you wish to join later on. Mark

the center of this piece’s width on one end and place

the board face down on the router table with the center

of the board aligned with the approximate center of the

bit. See Fig. 17.

Set initial fence position

Unlock the carriage clamp and slide the fence up to

the edge of the board, then lock the carriage clamp

back in place. See Fig. 18. Make sure the center mark

on the board is still aligned with the approximate center

of the router bit.

Test the fit and adjust as necessary

Unclamp the two boards and test the fit by joining

them as shown in Fig. 15. As with any half blind dovetail

jig, a little trial and error is needed to achieve a snug

fitting joint. To tighten the fit, raise the bit up slightly; to

loosen the fit, lower the bit slightly. Just remember this

phrase:

“Heighten to tighten, lower to loosen.” After

adjusting the bit height, make a new set of trial cuts on

the opposite end of the boards. After a few adjustments

and trial cuts, you’ll have a perfect fit. If you’ll mark the

properly fitting cuts on one edge of the boards, you can

save this piece to use as a depth gauge the next time

you set up this particular bit for joinery.

7

FIG. 15

Test the fit

When the fit is too loose, the trial cuts provide a

gauge to let you know how much to raise the bit. Just

join the trial pieces end to end and gently pull the boards

to wedge the dovetails together. The gap that appears is

equal to the distance you need to raise your dovetail bit to

achieve a tight fit. See Fig. 16.

FIG. 16

FIG. 17

Align board with bit

FIG. 18

Set initial fence position

2

1

3

Gap

Raise bit this much

Mark center

of board

Center of board

aligned with

approximate

center of bit

First: Unlock

carriage clamp

Second: Slide fence

up to edge of board

Third: Lock carriage

clamp back in place