Flint & Walling CCF Series Air Induction Water Treatment Systems User Manual

Page 7

7

remier

remier

roducts

roducts

P

P

P

P

WATER TREATMENT

®

Addendum for CCF Series

Automatic Water Filters Only

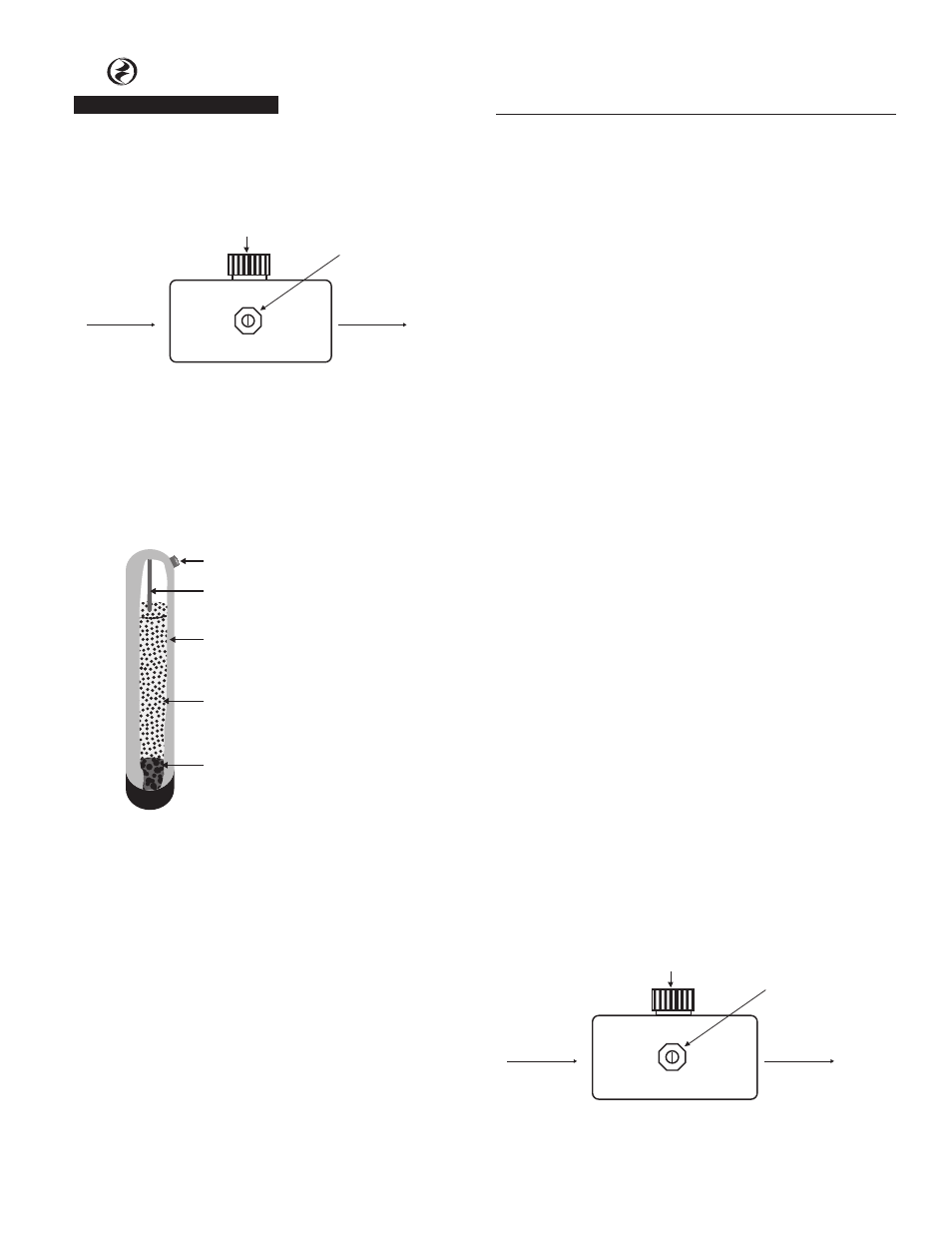

and pressure control switch is located on pressure

tank side of the air induction assembly (See Figure

2). Allow 8” of straight pipe on both sides of air

induction assembly.

WATER FLOW

WATER FLOW

FLOW ADJUSTING SCREW

SUCTION

PORT

IL1041

Figure 2 - Air Induction Assembly

INSTALLINg THE FILTER

1. Media was shipped separately. Carefully unscrew

the control valve. Be sure to “plug” the top of the

distributor tube using tape or some other means. Do

not allow filter media to enter inside of distributor

tube (See Figure 3).

Distributor Tube

Media Tank

Filter Media

Gravel - preinstalled

Dome Hole (”D” suffix models only)

Figure 3 - Media Tank Cutaway

2. Pour the separately shipped media into media tank.

3. Replace control valve on media tank. Lubricate

o-rings on control valve with silicone lubricant. DO

NOT USE PETROLEUM JELLY.

4. Lubricate bypass valve o-rings with silicone lubricant

and secure to the control valve using adapter

couplings, clips and screws.

5. Cut main supply line as required to fit plumbing to

the inlet and outlet of bypass valve. Make certain

water flow enters through the Inlet and discharges

through the Outlet of bypass valve.

6. Attach drain line to drain line fitting. Position drain

line over drain and secure firmly. To prevent back

siphoning, be sure to have adequate air gap of at

least 2 inches.

7. Make certain bypass valve is in the “bypass” position.

Turn on power to well pump or open main supply

valve completely.

8. Plug control valve into a non-switched 115V power

source.

9. Manually stage filter to the backwash position (see

service manual).

10. Open inlet valve and allow the unit to fill SLOWLY.

This will allow air to escape from the media tank.

Once water continually flows to drain, open both

inlet and outlet valves fully.

11. Check for leaks and allow filter to backwash for at

least 10 minutes, or until water flowing from drain

runs clear.

12. Allow unit to fully regenerate (see service manual).

13. Models CCF10D and CCF20D have a dome hole/plug

located in the upper dome of the mineral tank. This

is used to replenish mineral as required. DO NOT

remove dome hole plug without first depressurizing

the tank.

ADJUSTINg THE AIR INDUCTION ASSEMBLy

1. Open nearest faucet until pump starts, then close

faucet.

2. Place finger lightly over SUCTION PORT (See figure 2).

A slight suction should be detected for approximately

ONE-THIRD of pumping cycle. (Do not confuse with

one-third of PRESSURE RANGE).

3. If suction duration is too short, increase by turning

FLOW ADJUSTING SCREW CLOCKWISE. To decrease

duration, turn COUNTER CLOCKWISE.

4. Repeat steps 1 through 3 until proper setting is

obtained.

NOTE: When the duration of the suction is too long, cold

water may have a “milky” appearance caused by excess

air in the system. Correct this condition by reducing the

duration of suction. This condition is commonly associated

with bladder type pressure tanks In extreme cases where

elimination of excess air prevents system from performing

satisfactorily, it may be necessary to install a standard air-

to-water type pressure tank with an air relief valve.

WATER FLOW

WATER FLOW

FLOW ADJUSTING SCREW

SUCTION

PORT

IL1041

Figure 2