Before installing your filter, Installation, Remier – Flint & Walling CCF Series Air Induction Water Treatment Systems User Manual

Page 6: Inspection and handling your filter, Conduct a thorough water test, Water analysis, Locating equipment correctly, Facts to remember while planning your installation, Check water pressure, Check pumping rate of well pump

6

remier

remier

roducts

roducts

P

P

P

P

WATER TREATMENT

®

Addendum for CCF Series

Automatic Water Filters Only

BEFORE INSTALLINg yOUR FILTER

INSPECTION AND HANDLINg yOUR FILTER

Be sure to inspect the equipment for shipping damage

and notify the transportation company if damage exists.

Handle the filter with care, as damage can result if

dropped or if the filter is set on a sharp object.

CONDUCT A THOROUgH WATER TEST

Your water should have a thorough analysis prior to the

selection of water conditioning equipment. Enter your

analysis below:

WATER ANALySIS

IRON (fe)

__________ ppm

Manganese (Mn)

__________ ppm

pH

__________

Tannins

__________ ppm

Hydrogen Sulfide (H2S)

__________ ppm

NOTE: Hydrogen Sulfide must be tested at the well site.

Failure to conduct an “on site” analysis will result in

inaccurate test results.

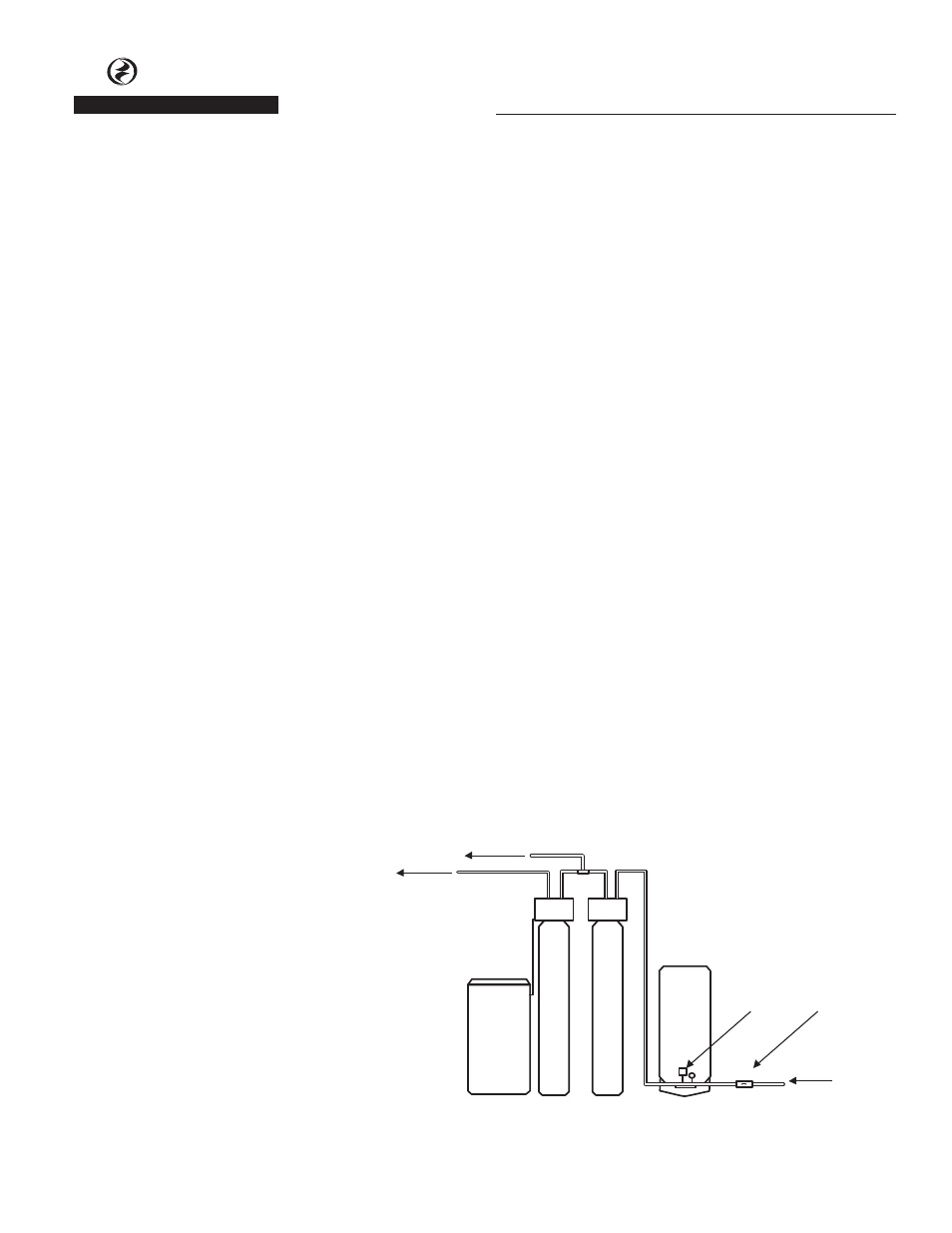

LOCATINg EQUIPMENT CORRECTLy

The location of your filter should be selected carefully. A

variety of conditions will contribute to proper location as

follows:

1. Locate as close as possible to the source of water

supply.

2. Locate as close as possible to drain, i.e. laundry tub or

floor drain.

3. Locate in correct relationship to other water

treatment equipment (See Figure 1).

4. Allow sufficient area around the equipment for

service.

FACTS TO REMEMBER WHILE

PLANNINg yOUR INSTALLATION

1. All installation procedures MUST conform

to local and state plumbing codes.

2. All water MUST pass through the air

induction assembly, pressure tank and

the Chemical-Free Iron Filter (See Figure

1)

3. If lawn sprinkling, a swimming pool or

geothermal heating/cooling are to be

treated by the Chemical Free filter, a

larger model filter MUST be selected

to accommodate the higher flow rate

demands.

4. IMPORTANT: Always use Teflon tape on threaded

plastic fittings. NEVER use pipe dope, as it will

deteriorate the plastic fittings.

CHECK WATER PRESSURE

Minimum water pressure required at the inlet of the

filter is 30 psi. IF PRESSURE IS OVER 125 PSI, A PRESSURE

REGULATING VALVE MUST E INSTALLED TO REDUCE

WATER PRESSURE.

NOTE: Pressure regulating valve must be installed in

water line ahead of the air induction assembly.

CHECK PUMPINg RATE OF WELL PUMP

The pumping rate of your well pump must be sufficient

to properly backwash the filter. Check backwash flow rate

required for specific filter model.

Water Pressure

Low

_____ PSI

High

_____

PSI

Pumping Rate

_________ GPM

INSTALLATION

INSTALLINg THE AIR INDUCTION ASSEMBLy

1. Shut off all water at the main supply. On a private

well system, turn off power to the pump and drain

pressure tank. Make sure pressure is relieved from

complete system by opening nearest faucet to drain

system. SHUT OFF FUEL SUPPLY TO WATER HEATER.

2. Cut main supply line as required to fit air induction

assembly in plumbing between well pump and

pressure tank. Air induction assembly may be installed

in a vertical or horizontal position. Position air

induction assembly so that the flow adjusting screw

is accessible for adjustment by screwdriver. Install

unions to facilitate air induction assembly removal

and inspection. Be certain the Flow Arrow on air

induction assembly points toward the pressure tank

Figure 1 - Standard Installation

IRON FREE WATER

IRON FREE

SOFT WATER

WATER

SOFTENER

WATER

FILTER

PRESSURE

TANK

PRESSURE

SWITCH

AIR INDUCTION

ASSEMBLY

WELL WATER

FROM PUMP

IL1040