Troubleshooting chart – Flint & Walling FJ Shallow Well User Manual

Page 8

© Copyright 2006. All rights reserved.

8

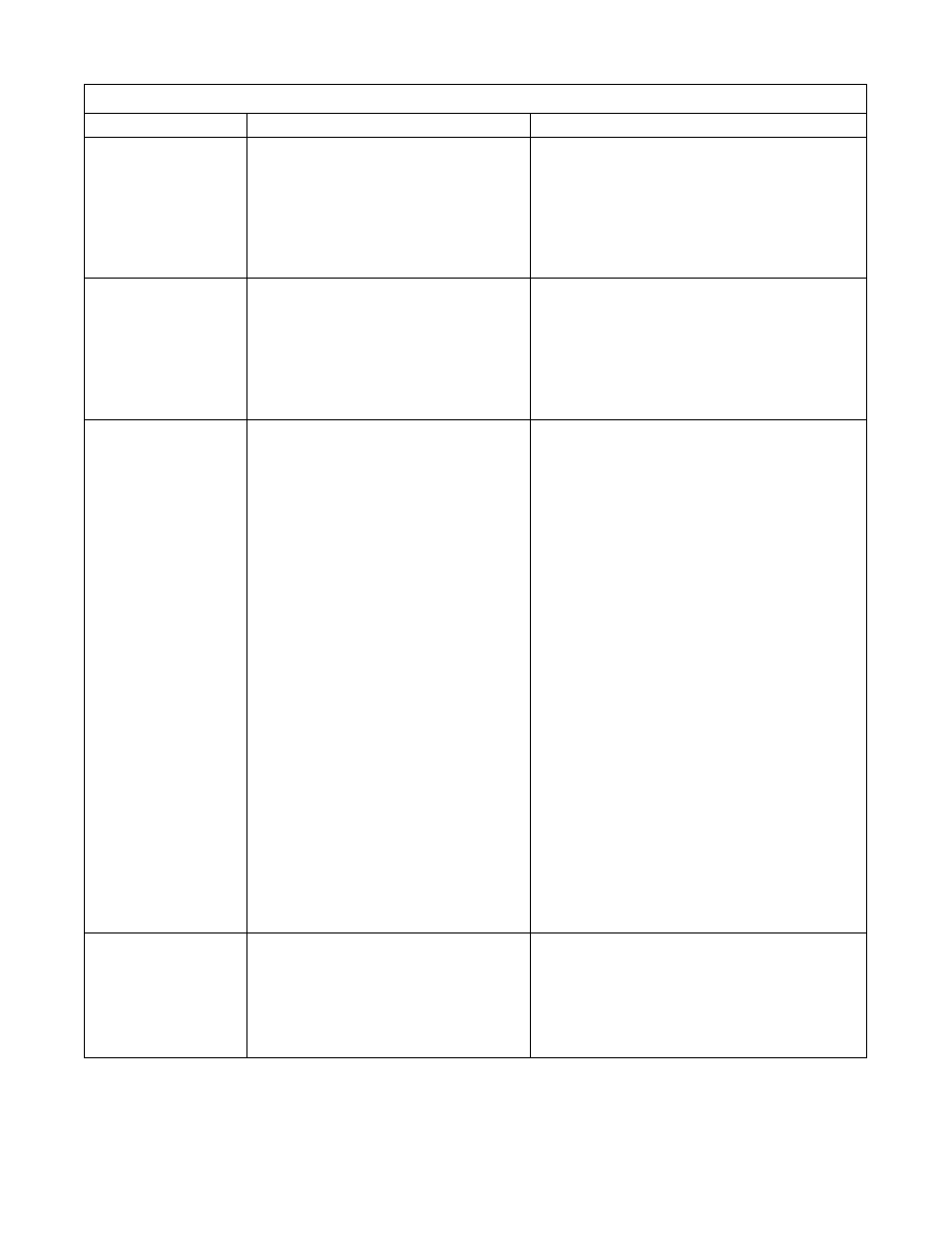

TROUBLESHOOTING CHART

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

A. MOTOR WILL NOT

RUN

1. Disconnect switch is off.

2. Fuse is blown.

3. Starting switch is defective.

4. Pressure switch contacts are dirty.

1. Be sure switch is on

2. Replace

fuse

3. Disconnect power; replace starting switch

4. Disconnect power and file contacts with emery

board or nail file

B. MOTOR RUNS HOT

AND OVERLOAD

KICKS OFF

1. Motor is wired incorrectly.

2. Voltage is too low.

3. Pump cycles too frequently.

1. Refer to instructions on wiring

2. Check with power company. Install heavier

wiring if wire size is too small. See wiring

instructions

3. See section below on too frequent cycling

C. MOTOR RUNS

BUT NO WATER IS

DELIVERED

(*) NOTE: Check prime

before looking for

other causes. Unscrew

priming plug and see

if there is water in

priming hole

1. Pump in a new installation did not pick

up prime through:

a. Improper

priming

b. Air

leaks

c.

Leaking foot valve

*2. Pump has lost its prime through:

a. Air

leaks

b.

Water level below suction of pump

3. Ejector or impeller is plugged

4. Check valve or foot valve is stuck in

closed position

5. Pipes are frozen

6. Foot valve and/or strainer are buried in

sand

1. In new installation

a. Re-prime according to instructions

b. Check all connections on suction line, air

volume control and ejector

c.

Replace foot valve

2. In installation already in use:

a. Check all connections on suction line, air

volume control, ejector and shaft seal

b. Lower suction line into water and re-

prime. If receding water level in a shallow well

operation exceeds suction lift, a deep well pump

is needed

3. Clean ejector or impeller

4. Replace check valve or foot valve

5. Thaw pipes. Bury pipes below frost line. Heat

pit or pump house

6. Raise foot valve and/or strainer above well

bottom

D. PUMP DOES NOT

DELIVER WATER

TO FULL CAPACITY

(ALSO CHECK POINT

3 IMMEDIATELY

ABOVE)

1. Water level in well is lower than

estimated.

2. Steel piping (if used) is corroded or

limed, causing excess friction

3. Offset piping is too small in size

1. A deep well jet pump may be needed (over 25

ft. to water)

2. Replace with plastic pipe where possible,

otherwise with new steel pipe

3. Use larger offset piping