Flint & Walling FJ Shallow Well User Manual

Page 2

© Copyright 2006. All rights reserved.

2

General Safety Information

Carefully read and follow all safety instructions

in this manual and on pump. Keep safety labels

in good condition. Replace missing or damaged

safety labels.

This is a SAFETY ALERT SYMBOL. When you

see this symbol on the pump or in the manual,

look for one of the following signal words and

be alert to the potential for personal injury or

property damage.

Warns of hazards that will cause

serious personal injury, death or major property

damage if ignored.

Warns of hazards that can cause

serious personal injury or death, if ignored.

Warns of hazards that can cause

minor personal injury, product or property damage if

ignored.

Indicates factors

concerned with operation, installation, assembly or

maintenance which could result in damage to the

machine or equipment if ignored.

NOTE: Indicates special instructions which are

important but are not related to hazards.

Do not use to pump flammable or explosive

fluids such as gasoline, fuel oil, kerosene,

etc. Do not use in flammable and/or

explosive atmospheres.

Hazardous pressure! Install pressure

relief valve in discharge pipe. Release all

pressure on system before working on any

component.

This product contains chemicals

known to the State of California to cause cancer and

birth defects or other reproductive harm.

NOTE: Pumps with the cCSAus mark are tested to

UL Standard UL778 and certified to CSA Standard

C22.2 No. 108.

1. Wear safety glasses when working with pumps.

2. Pump water only with this pump.

3. Periodically inspect pump and system

components.

4. Protect electrical cord. Replace or repair

damaged or worn cords immediately.

5. Do not insert finger or any object into pump or

motor openings.

6. Do not allow pump or any other system

component to freeze. Freezing may damage

system, leading to injury or flooding. Allowing

pump or system components to freeze will void

the warranty.

7. An acceptable motor switch shall be provided at

the tme of installation.

Never examine, make wiring

changes or touch the motor before disconnecting the

main electrical supply switch.

Unpacking

1. Open carton and remove package that has been

packed with the pump. This package contains

the pressure switch.

2. Remove pump from carton.

3. Check for loose, missing or damaged parts.

IL0607

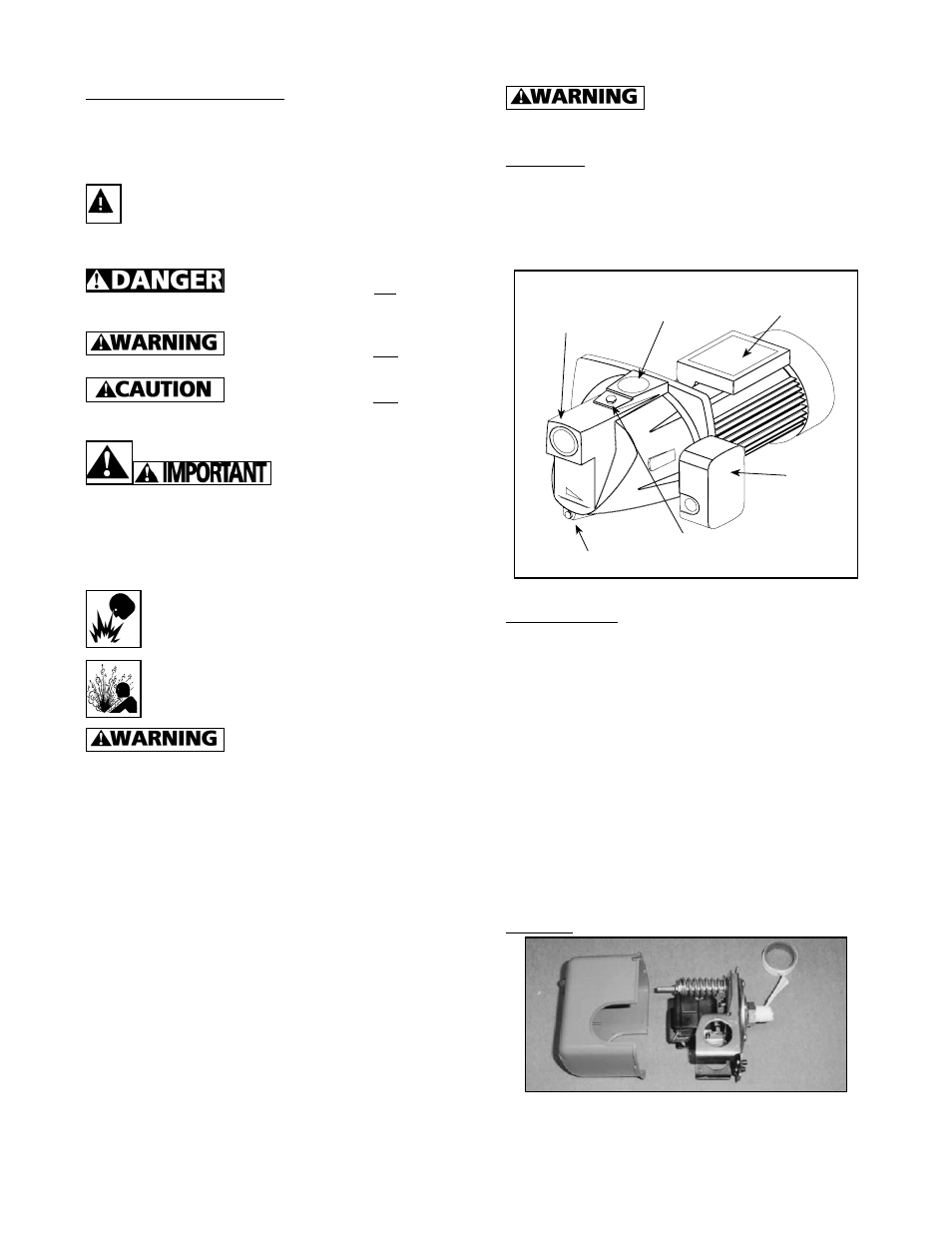

1” NPT

Discharge

Port

1-1/4” NPT

Suction Port

Pressure

Switch

1/2” Priming

Port

Drain Plug

Junction Box

Figure 1

Pre-Installation

For installation the following general materials may

be required:

• PVC cement (if plastic pipe is used)

• Teflon tape

• Pipe, pipe couplings and fittings

• 1” nipple (for discharge)

• 1” tee or 90° elbow (for discharge)

* 1” pipe plug if tee is used

• 1-1/4” foot valve (for cased wells)

• 1-1/4” check valve (for driven wells)

• Single pipe well seal for 1-1/4” pipe (cased or

dug wells)

• Copper electrical wire (See Wiring in Electrical)

• Romex strain relief for pressure switch

Assembly

1. Apply two (2) wraps of Teflon tape to threads of

the pressure switch screw. Refer to Electrical

section for pressure switch wiring.