Flint & Walling FJ Shallow Well User Manual

Page 3

© Copyright 2006. All rights reserved.

3

Assembly (Continued)

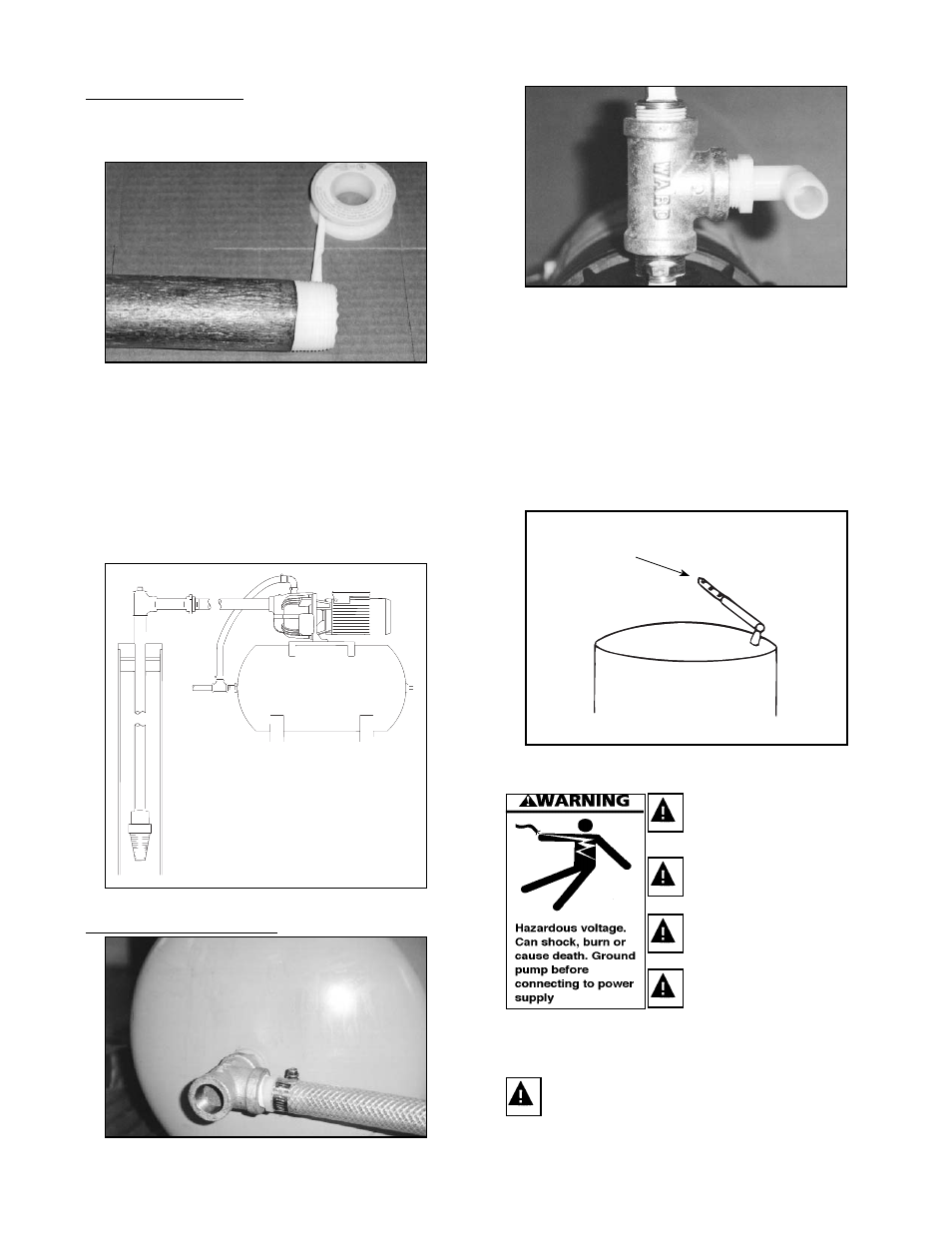

2. Screw in pressure switch to 1/4” tapping on side

of pump hand tight. Tighten pressure switch with

wrench.

3. Use Teflon tape or pipe joint compound for

making all threaded connections to the pump.

4. Assemble 3/4” pipe to discharge port of pump.

Assemble suction pipe with union to front

of pump. Unions installed near pump and

well will aid in servicing. Leave room to use

wrenches.Tighten joints to approximately 140 ft.

lbs.

5. Bolt pump to solid, level foundation. Support all

piping connected to the pump.

IL0155

Figure 2

Pressure Tank Installation

1. Assemble tank Tee to end of tank. Screw flexible

hose to tank Tee.

2. Screw elbow fitting to discharge tee. Push flexible

hose onto elbow. Tighten clamp with screwdriver.

3. Connect service line to tank Tee.

4. NOTE: DO NOT install a check valve between

pump and pressure tank. This will cause the

pressure switch to malfunction.

IMPORTANT: Your pump pressure switch is set for

a 20-40 PSI (1.4 - 2.8 Kg/cm2) range and requires

a tank pre-charge of 18 PSI for proper operation

(See Figure 7.)

IL0167

Checking Tank Pre-Charge

Check pressure

with tire gauge

Pre-Charged Pressure

Tank

Figure 3

Ground motor before

connecting to electrical

power supply

Failure to ground motor

can cause severe or fatal

electrical shock hazard

Do not ground to a gas

supply line.

To avoid dangerous or fatal

electrical shock, turn off

power to motor before

working on electrical

connections.

Supply voltage must be within ±10% of

nameplate voltage. Incorrect voltage can

cause fire or seriously damage motor and

voids warranty. If in doubt, consult a licensed

electrician.

3