Installation (continued) – Flint & Walling Pressure Booster Pumps Instructions User Manual

Page 6

6

Copyright © 2014 FLINT & WALLING, INC. • 95 North Oak St. • Kendallville, IN 46755

flintandwalling.com

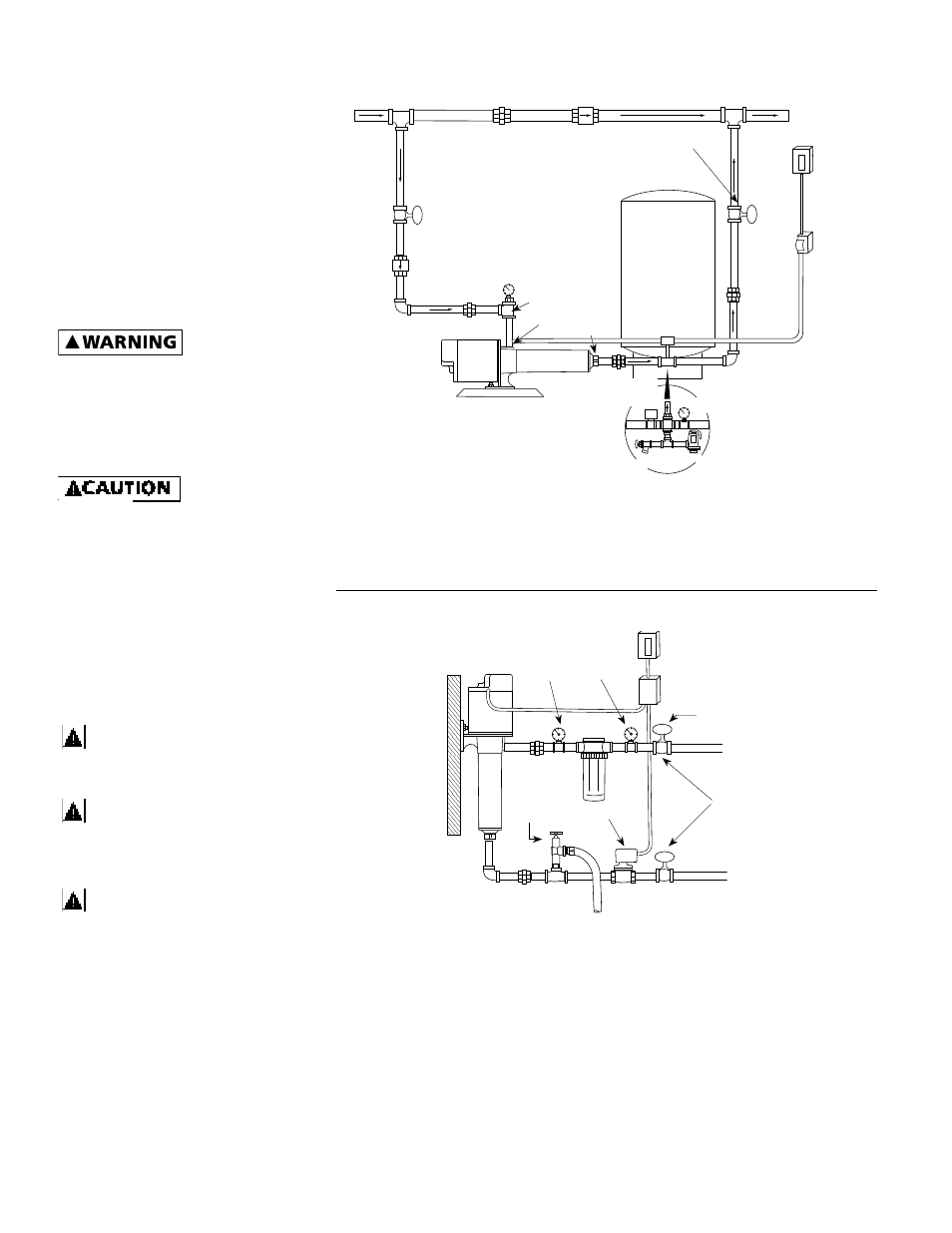

Installation (Continued)

5. A pressure gauge installed in

the inlet pipe close to the inlet

port, (See Figure 6) will show if

enough water is being supplied

to the pump. See Operation

Section - Priming, Pressure Boost

Installations.

6. On installations that are using

nozzles for mist spraying, install

a filter in the discharge plumbing

to prevent the nozzles from

becoming plugged. Multiple filters

should be plumbed in parallel.

!

Install a pressure

relief valve on any

installation where

pump pressure can exceed the pressure

tank’s maximum working pressure or

on systems where the discharge line

can be shut off or obstructed. Extreme

over pressure can result in personal

injury or property damage.

This unit is not

waterproof and is

not intended to be

used in showers, saunas or other

potentially wet locations. The motor is

designed to be used in a clean dry

location with access to an adequate

supply of cooling air. Ambient

temperature around the motor should

not exceed 104ºF (40ºC). For outdoor

installations, motor must be protected

by a cover that does not block airflow

to and around the motor. This unit is

not weatherproof nor is it able to be

submersed in water or any other

liquid.

To avoid dangerous or fatal

electrical shock, turn off power to

motor before working on electrical

connections.

Supply voltage must be within ±

10% of nameplate voltage. Incorrect

voltage can cause fire or seriously

damage motor and voids warranty. If

in doubt, consult a licensed electrician.

Use wire size specified in wiring

Chart F. If possible, connect pump

to a separate branch circuit with no

other appliances on it. If motor wiring

diagram differs from diagram shown

below, follow diagram on motor.

Figure 6

IMPORTANT: A contained air pressure tank and pressure switch is required to

keep the pump from rapid cycling and prevent the motor from over heating.

Install the tank and switch on the house side of system.

Pump used to boost water pressure in mist spray applications (automatic

operation).

NOTE: Install solenoid valve on discharge side of pump.

Pump used to boost incoming city pressure (automatic operation).

IMPORTANT: Clean all filters and strainers on a regular schedule.

IL0423

IL0422

Street Supply

Union

Check Valve

Gate/Ball

Valve

(Normally

open)

Main Power Box

Fuse

Box or

Switch

Union

Pressure

Gauge

Drain

To size tank

properly - Match

drawdown of

tank to capacity

of pump

Union

Pressure

Relief

Valve

Pressure

Switch

Pressure Switch

Gate/Ball

Valve

(Normally

open)

Inlet

Pressure

Gauge

Check

Valve

Outlet

Service Tee

Fuse Box

or Switch

Thermostat

Gate/Ball Valve

From Water Source

Gate/Ball Valve

(Normally open)

To Nozzles

To Drain

Pressure Gauge

Line Filter

Solenoid

Valve

Pressure

Relief

Valve

Figure 7