Preliminary test run, Controller location selection, Correct incorrect – Flint & Walling Commander Pro 75 User Manual

Page 6: Wiring

6

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

IMPORTANT: Well seal and piping must be protected

from freezing.

2. On a pitless adapter installation, the connection to the

system supply line is made below ground. Install the

pitless adapter following the instructions included with

particular brand or design being used in the installation.

NOTE: Follow ALL applicable state and local plumbing

codes.

PRELIMINARY TEST RUN

1. When pump is at desired depth, install throttle valve

for preliminary test run. Test cable for continuity with

an ohmmeter.

2. With pump discharge throttled, run pump until water is

clear of sand or any other impurities. Gradually open

discharge.

Be sure you do not stop pump before

water runs clear. This may take several hours. If pump

stops with sand in it, it will lock.

3. If pump lowers water in the well far enough to lose

prime lower pump in the well.

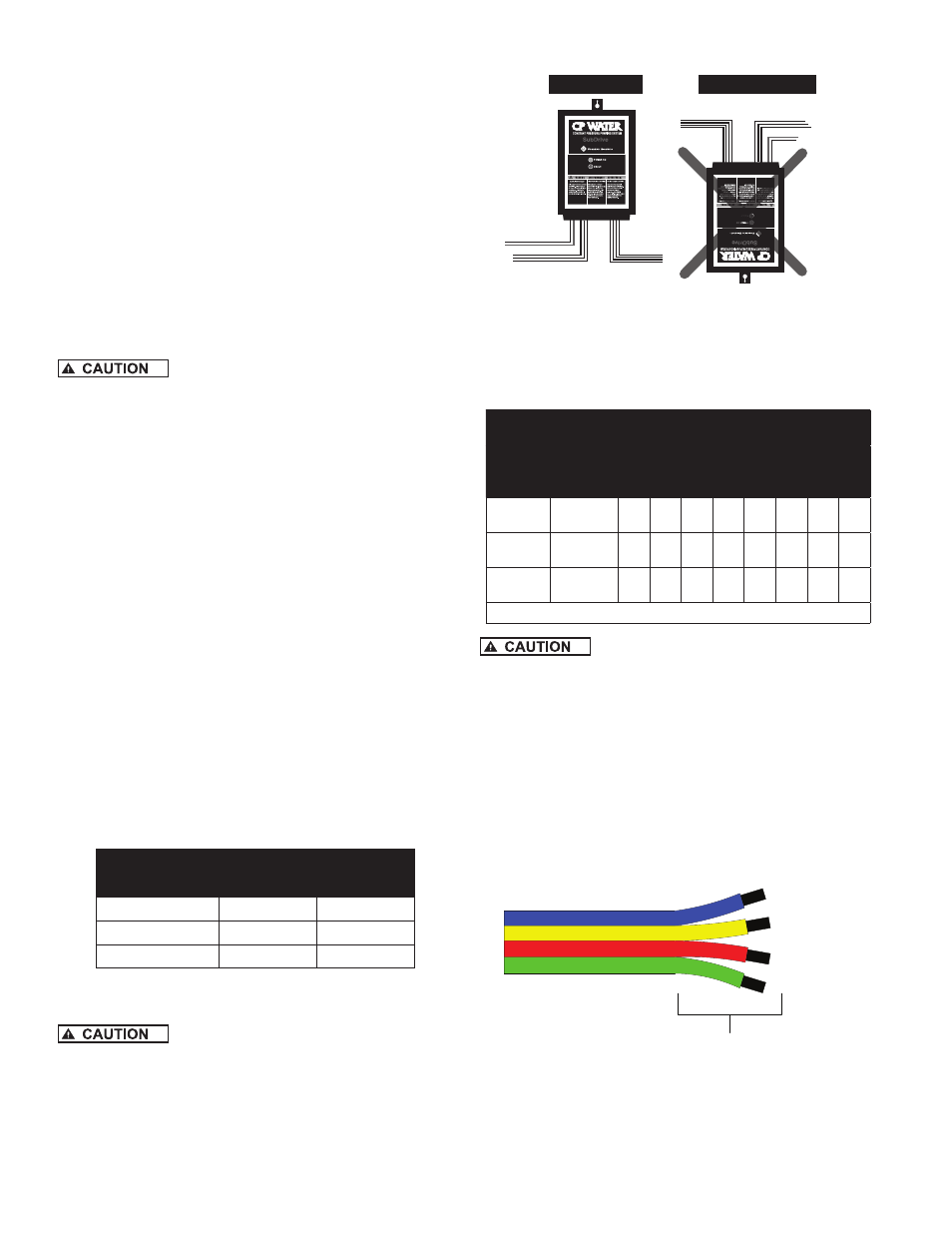

CONTROLLER LOCATION SELECTION

The CP WATER Subdrive standard NEMA 1 controller

is intended for indoor use and for operation in ambient

temperatures up to 125° F (50° C) at rated input voltage.

For outdoor installations, a system with a NEMA 4

rated controller must be used. (Models with 8th and

9th characters of “N4”). To ensure maximum weather

protection, the unit must be mounted vertically with the

cover properly aligned and secured with all lid screws.

The following recommendations will help in selection of

the proper location of the CP WATER Subdrive 100 unit:

1. A tank tee is recommended for mounting the tank,

pressure sensor, pressure gauge, and pressure relief

valve at one junction. If a tank tee is not used, the

pressure sensor should be located within 6 ft. (1.8

meters) of the pressure tank to minimize pressure

fluctuations. There should be no elbows between the

tank and pressure sensor.

2. The unit should be mounted on a sturdy structure such

as a wall or supporting post.

Unit Weight

Model

NEMA 1

NEMA 4

Subdrive 75

15.0 lbs.

24.14 lbs.

Subdrive 100

17.5 lbs.

28.32 lbs.

Subdrive 150

17.5 lbs.

28.32 lbs.

3. The electronics inside the CP WATER Subdrive are

air-cooled. Allow room for air flow when installing.

There should be at least six inches of

clearance on each side and below the unit to allow room for

airflow.

4. The CP WATER Subdrive should only be mounted

with the wiring end oriented downward. The

controller should not be placed in direct sunlight or

other locations subject to extreme temperatures or

condensation).

CORRECT

INCORRECT

IL0877

Pressure

Sensor Wiring

Wiring

To Motor

Power Supply

From Circuit Breaker

Wiring

To Motor

Power Supply

From Circuit Breaker

Pressure

Sensor Wiring

Figure 5

5. The mounting location should have access to 230V,

electrical supply and to the submersible motor wiring.

WIRING

Maximum wire lengths connecting the CP controller

to the main circuit box

Subdrive

Copper

Wire size

(AWG)

14

12

10

8

6

4

3

2

Subdrive

75

Max.

Length (Ft.) 85 135 225 345 550 865

Subdrive

100

Max.

Length (Ft.)

85* 140* 220 345 550 680 895

Subdrive

150

Max.

Length (Ft.)

115* 180 285 455 560 740

*Wire with 90°C insulation only.

Due to the inherent voltage changing

characteristics of variable frequency drives (VFD), there

is additional stress placed on the insulation of the wire

between the controller and the motor compared to a

standard pump system. Extra care must be taken when

using Unjacketed Flat Parallel Pump Cable to ensure that

the insulation on each of the separated wires is the same

thickness. Care must also be taken to ensure a proper

seal with shrink tubing on any splices. Failure to take

these precautions can lead to “wire burn through” that

will shut down the system. Under these circumstances,

no permanent damage usually occurs to the controller or

motor. For further details call Technical Support at

1-800-742-5044.

SEPARATED WIRE

Figure 6

NOTE: DO NOT USE ALUMINUM WIRE.