Flint & Walling Commander Pro 75 User Manual

Page 3

3

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

MAJOR WELL COMPONENTS

1. Submersible Pump — A submersible pump is a multi-

stage centrifugal. Each stage consists of an impeller

and diffuser. Water pressure increases in equal

amounts as it passes from stage to stage. The more

stages, the higher the pressure the pump will develop.

2. Submersible Motor — The submersible motor is

powered by three phase electricity. Make sure the

motor is designed for three phase operation.

3. Subdrive Controller — Subdrive is designed for use

in residential and light commercial applications with a

3-phase submersible motor using single-phase input.

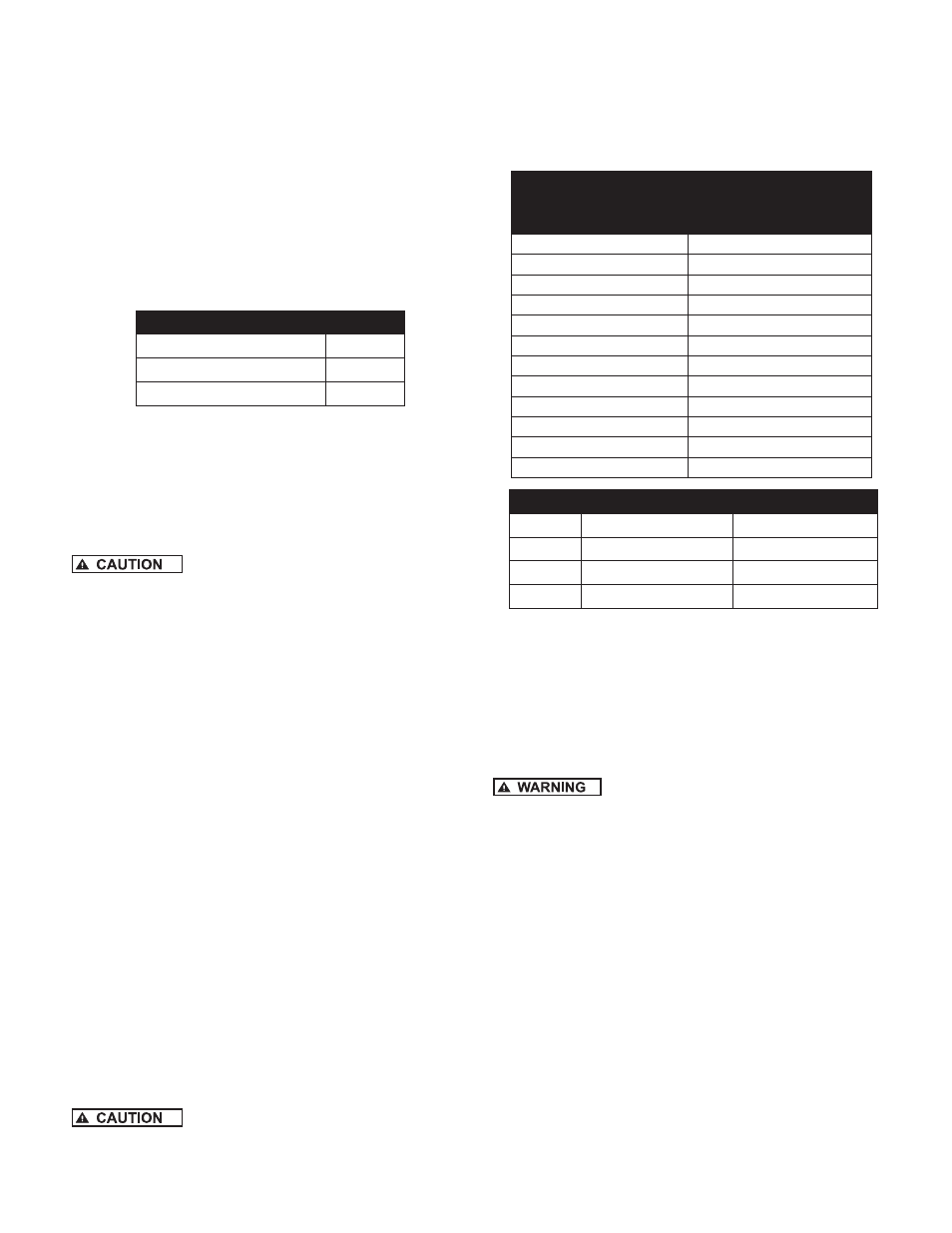

Motor Design Designation

Subdrive 75 Controller

1-1/2 HP

Subdrive 100 Controller

2 HP

Subdrive 150 Controller

3 HP

This variable speed controller can be used to provide

constant pressure delivery over a wide range of

settings (25 to 80 PSI). Factory preset is 50 PSI.

4. The Well — The well should be sand free and have a

sufficient flow of water to supply the pump. Clear well

of sand and any other foreign matter with a test pump

before installing the new submersible pump.

Using the submersible pump to clean the

well will void the warranty.

a. When drilling a new well in an area where sand is

a problem, a sand screen should be installed to

protect the pump and motor.

b. The well should be straight so damage during

installation does not occur to the pump or motor by

becoming lodged in a crooked well casing.

c. The complete pump and motor should be

submerged at least ten feet below the draw

down level of the well, and the motor should be a

minimum of ten feet off the bottom of the well.

5. The Piping — Install the pump with pipe of the same

diameter as the discharge port of the pump or larger.

NOTE: Use of pipe smaller than the discharge port of the

pump will restrict the capacity of the pump and lower its

operating performance.

6. Check Valve — A check valve is required on all

submersible installations. This valve maintains water

within the pipe when the pump is not running. A line

check should be installed within 25 feet of the pump

and below the draw down level of the water supply.

a. For well depths exceeding 200 feet, it is suggested

that an additional check valve be installed every

125 feet.

b. An additional check valve should be installed in the

horizontal line between the well top and the pressure

tank.

Make certain that the check valve is

pointing in the right direction, arrow pointing towards the

tank.

7. Torque Arrester — To center the pump as it is

being lowered into the well, a torque arrester is

recommended.

8. Pressure Tank — Any change to operating system

pressure will require that the precharge in the tank be

modified to 70% of that pressure.

Pressure Setting Guide

System Pressure

(at Pressure Sensor)

Pressure Tank Setting

(PSI) (+/- 2 psi)

25

18

30

21

35

25

40

28

45

32

50 (factory set)

35

55

39

60

42

65

46

70

49

75

53

80

56

Required Tank Size

10 gpm and smaller 19 gpm and larger

CP75

2 gallons

4 gallons

CP100

4 gallons

8 gallons

CP150

4 gallons

8 gallons

9. Pressure Relief Valve — The pressure relief valve and

the discharge outlet need a flow rating which exceeds

the flow capacity of the installation at the relief

pressure. When located in an area where a water leak

or relief valve blow-off may damage property, connect

an adequate drain line to the pressure relief valve.

Run the line to a suitable drain or to an area where

the water will not damage property.

Not providing an adequate relief valve

can cause extreme overpressure which could result in

personal and/or property damage. It is recommended that

you manually activate the valve monthly to keep it in good

working condition.

10. Pitless Adapter — A pitless adapter provides below

grade discharge while maintaining above grade

access to the well. Placed below the frost line they

are frost proof and also prevent well contamination by

providing a water tight seal between the vertical drop

pipe and the horizontal service pipe connection.

11. Well Seal — On well seal installations the piping in

the well projects above the well and is connected

above ground to the system piping by means of a tee

or elbow. Since the plumbing is above ground, it must

be protected from freezing.

12. Submersible Cable — Submersible power cable must

be UL listed for submersible pump application. Selecting

the proper cable size is important. Undersized cable

results in a too low voltage supply to the pump motor