Pre-installation, Important precautions – Flint & Walling Commander Pro 75 User Manual

Page 2

2

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

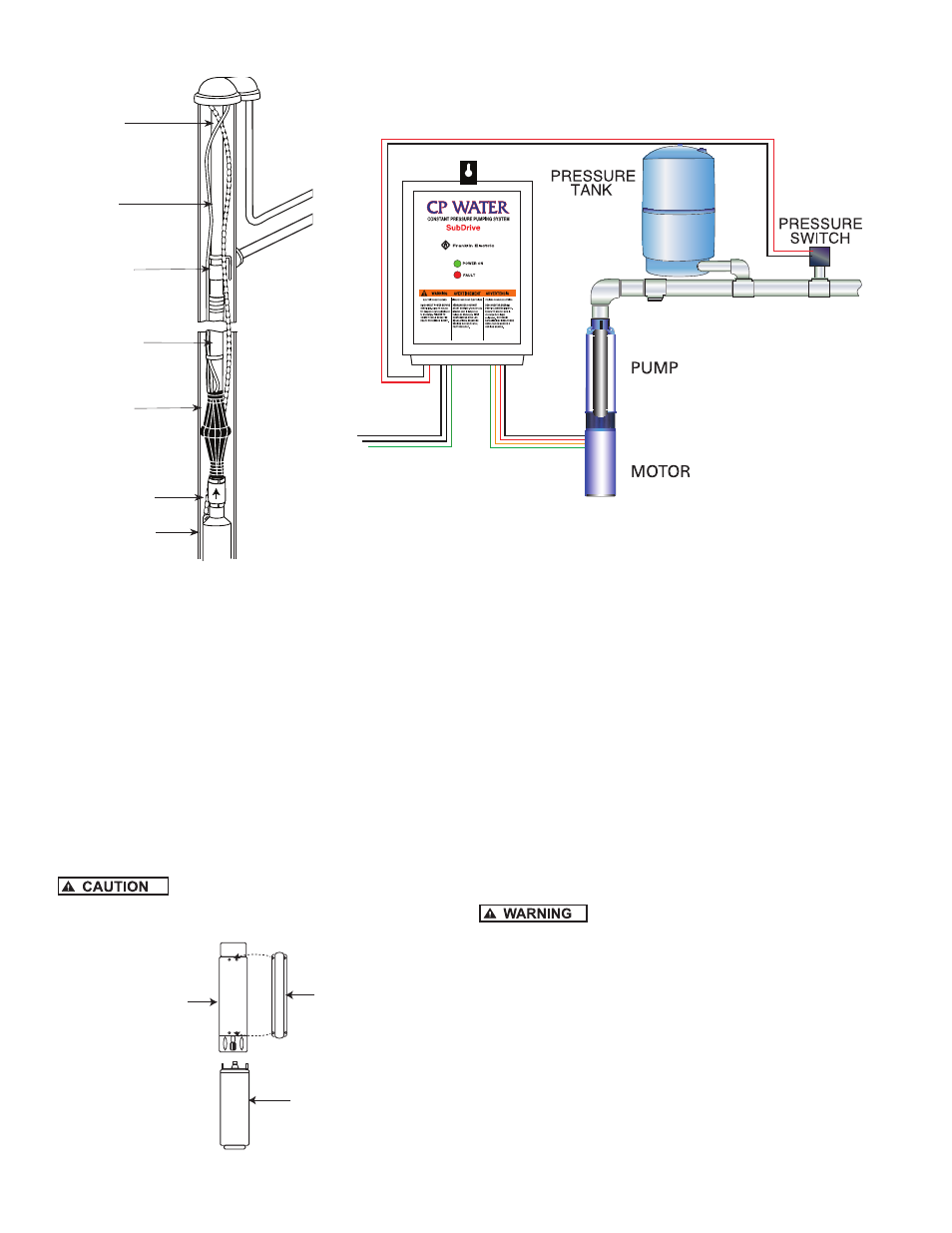

Typical Installation

Figure 1 — Typical Installation with Pre-Charged Tank

NEMA 1 SYSTEM

ONLY

Not supplied

with “LT” Models

PRESSURE RELIEF

VALVE

1. Check that the pump and motor mounting faces are

free from dirt.

2. Assemble the pump liquid end and motor together

so that mounting faces are in contact. Then tighten

assembly bolts evenly in a crossing pattern.

NOTE: Apply non-toxic FDA approved waterproof grease

such as Mobile 102, Texaco CYGNUS2661 or equivalent

to the coupling before assembly of pump coupling to

motor shaft. This will prolong spline life and prevent

abrasives from entering the spline area.

3. Check for free rotation of the pump and motor. A

slight drag is permissible.

4. Assemble the pump lead guard over the motor leads.

Do not cut or pinch lead wire during

assembly.

5. Assemble suction screen to pump mounting ring.

Liquid

End

Lead Wire

Guard

Motor

IL0094B

FIGURE 2

PRE-INSTALLATION

To save possible added expense and extra trips, observe

and complete as many as possible of the following

precautions and pre-installation procedures before going

to the job site or beginning the installation.

IMPORTANT PRECAUTIONS

1. Prior to installation, inspect the pump for damage.

Check for free pump and motor rotation. A slight drag

is permissible.

2. Check to make certain that the voltage of the motor

end and controls agree with the available phase

and voltage. Check power source. Check electrical

supply for correct fusing, correct wire size, and

adequate grounding and transformer size.

Since most submersible pump problems

are electrical, it is very important that all electrical work

be done properly. Therefore, all electrical hook-up work

or electrical service work should be done by a qualified

electrician or service man only!

3. Throughout installation, take care not to damage

the insulation of the electrical cable or motor leads.

Never support the weight of the unit by electrical cable

or motor leads.

4. Before the pump is installed, the well should be

pumped free of sand and other foreign matter with

a test pump.

The warranty is void if it is used to

clean the well.

READ THESE INSTRUCTIONS COMPLETELY BEFORE INSTALLATION

IL00074

Submersible

Cable

Riser

Pipe

Conduit

Pitless

Adapter

Plastic or

Steel Pipe

Torque

Arrestor

Check Valve

Submersible

Pump