Flint & Walling Commander Pro 75 User Manual

Page 4

4

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

and ultimate motor failure. Oversized cable is costly and

not necessary. Refer to cable selection chart for proper

cable selection. Cable is selected for the maximum

pump setting plus the offset distance to the service

entrance.

13. Ground Wire — The National Electric Code (NEC 250-

43) requires a separate ground wire be run down the

well to the submersible pump and to be connected to

all exposed metal parts of the pump and motor. Refer

to the most recent National Electric Code (NEC) for

additional grounding information. All wiring should be

done by a competent electrician.

INSTALLATION

SUBMERSIBLE CABLE INSTALLATION

1. Check power source. Check electrical supply for

correct fusing, correct wire size, and adequate

grounding and transformer size.

Since most submersible pump problems

are electrical, it is very important that all electrical work

be done properly. Therefore, all electrical hook-up work

or electrical service work should be done by a qualified

electrician or serviceman only!

2. Follow wiring directions in installation and operations

manual.

3. Check cable size against the Submersible Wire Size

Chart. Use extreme care; this is a very important

step. If required length falls between two wire sizes,

use the larger of the two wire sizes (smaller number).

IMPORTANT: Use of wire sizes smaller than those

specified in the charts will cause low starting voltage,

may cause early pump failure and will void the warranty.

Larger wire sizes may always be used for better operating

economy.

Maximum wire lengths connecting the motor to the controller

Subdrive

Copper Wire size

(AWG)

14

12

10

8

6

Subdrive 75 Maximum Length (Ft.) 420 670 1060 1670

-

Subdrive 100 Maximum Length (Ft.) 320 510 810 1280 2010

Subdrive 150 Maximum Length (Ft.) 240 390 620 990 1540

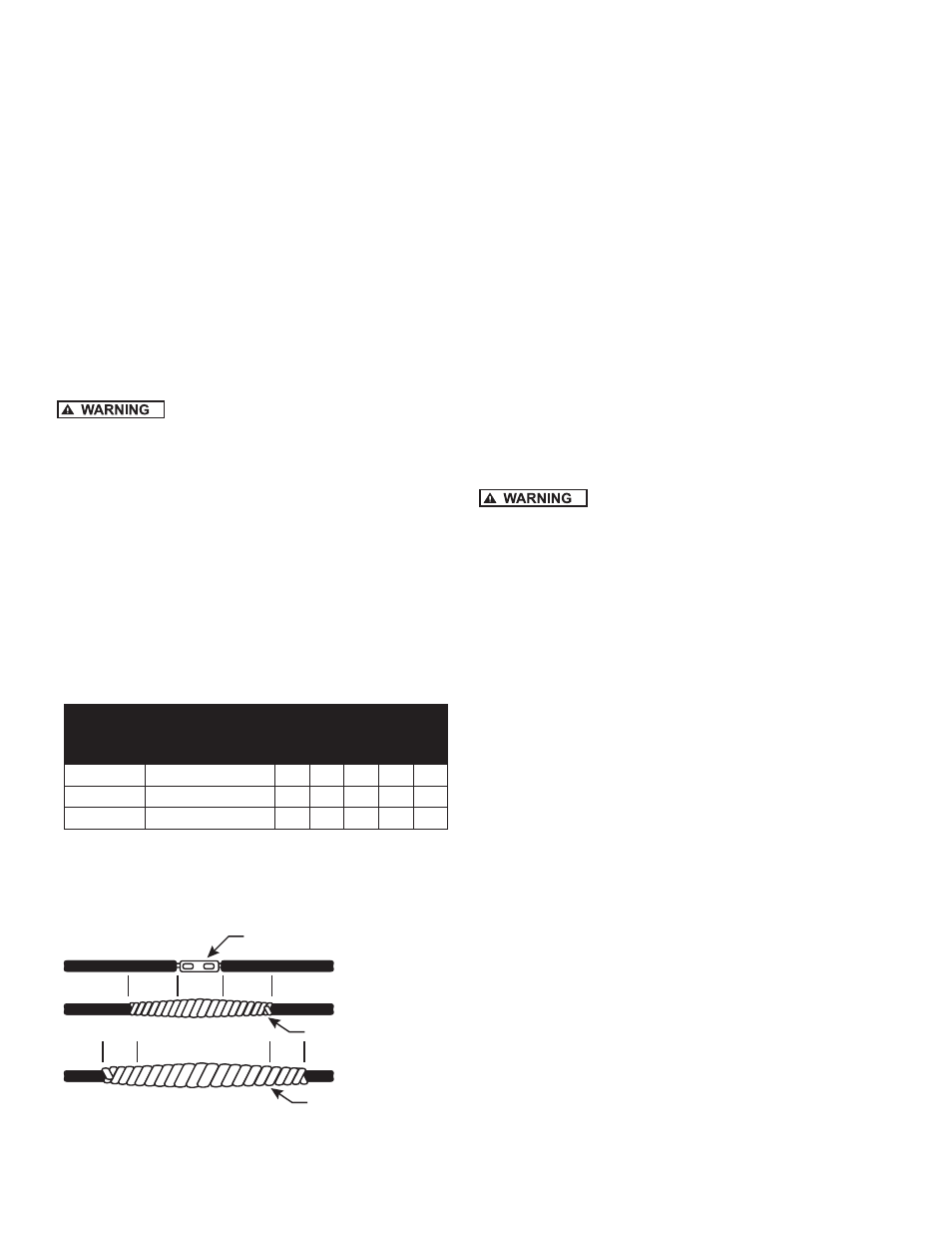

4. Splice motor leads to submersible cable with

commercially available potting, heat shrink splicing

kits or by careful tape splicing. Tape splicing should

use the following procedure.

Staked Connector

Rubber Tape

PVC Electrical Tape

2”

2”

2”

2”

IL0097

Figure 3

a) Strip individual conductor of insulation only as far

as necessary to provide room for a stake type

connector. Tubular connectors of the staked type are

preferred. If connector OD is not as large as cable

insulation, build-up with rubber electrical tape.

b) Tape individual joints with rubber electrical tape,

using two layers; the first extending two inches

beyond each end of the conductor insulation end,

the second layer two inches beyond the ends of the

first layer. Wrap tightly, eliminating air spaces as

much as possible.

c) Tape over the rubber electrical tape with #33

Scotch electrical tape, (Minnesota Mining Co.)

or equivalent, using two layers as in step “b” and

making each layer overlap the end of the preceding

layer at least two inches.

5. In the case of a cable with three conductors encased

in a single outer sheath, tape individual conductors as

described, staggering joints. Total thickness of tape

should be less than the thickness of the conductor

insulation.

GROUND WIRE INSTALLATION

Motor frame must be connected to power

supply ground or fatal electrical shock may result.

NOTE: All electrical wiring should be done by a

competent electrician.

1. Grounding the submersible pump is accomplished by

running a copper grounding wire from the pump motor

to the main electrical system ground.

2. The ground wire to be used must be of the same size

as the submersible power cable. It may be insulated

or bare. If insulated, it must be green, with or without

yellow stripe(s). The ground wire may be part of, or

separate from, the supply cable. It may be continuous

or spliced above the pump along with the supply

cable.

3. The motor lead wire assembly includes a green

insulated ground lead. Splice the ground wire to the

green insulated lead.

4. The other end of the ground wire will be connected to

the power supply grounding terminal or to the control

panel ground bar if it is connected to the power supply

ground.

NOTE: See section entitled Grounding for detailed

grounding instructions.

INSULATION AND CONTINUITY TEST

1. It is recommended that this test be done when the

splicing is complete and pump is being test run in

a tank of water. This test can be repeated after

installation in well but before the final electrical hook-

up is made to the control box or pressure switch.