Flint & Walling Constant Pressure Pumping Stations - end suction centrifugal pumps User Manual

Page 7

7

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

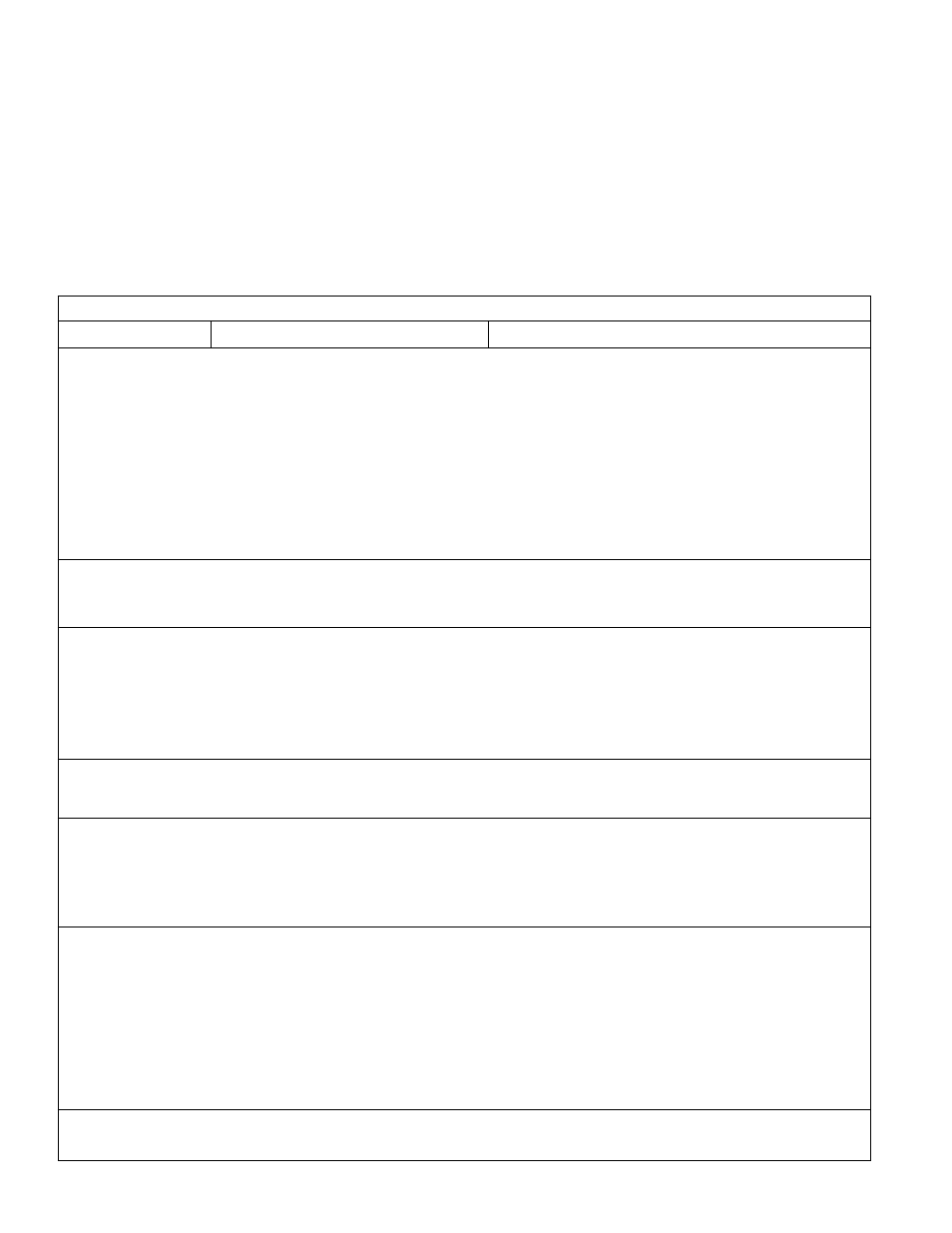

Troubleshooting Chart

Symptom

Possible Cause(s)

Corrective Action

Low or no discharge

1. Incorrect rotation

1. Refer to wiring diagram

2. Insufficient inlet pressure or suction head

(NPSH Required)

2. Increase inlet pressure by adding more fluid to fluid

source. (See Spec’s for minimum NPSH Required)

3. Total head too high

3. Lower discharge head

4. Leak in suction line

4. Repair or replace

5. Impeller clogged or damaged

5. Clean or replace

6. Wrong size piping

6. Make needed adjustments

7. Casing gasket leaking

7. Replace gasket

8. Suction or discharge line valves closed

8. Open

9. Mechanical seal leaking

9. Replace

Loss of suction

1. Insufficient inlet pressure or suction head

(NPSH Required)

1. Increase inlet pressure by adding more fluid to fluid

source. (See Spec’s for minimum NPSH Required)

2. Clogged strainer

2. Clean or replace

Pump vibrates and/or

makes excessive noise

1. Mounting plate or foundation not rigid

enough

1. Reinforce

2. Foreign material in pump

2. Clean

3. Damaged impeller

3. Replace

4. Cavitation present

4. Check suction line for proper size and be sure valve is

open. Remove excessive loops in suction line. (See Spec’s

for minimum NPSH Required)

Pump leaks at shaft

1. Damaged or worn mechanical seal

1. Replace

2. Corrosion due to character of liquid

pumped

2. Discontinue pumping liquid and consult factory

Pump will not start or

run

1. Improperly wired

1. Refer to wiring diagram

2. Blown fuse or open circuit breaker

2. Replace fuse or close circuit breaker

3. Loose or broken wiring

3. Tighten connections and replace broken wiring

4. Impeller clogged

4. Clean

5. Motor shorted out

5. Replace

Motor problems

1. Various

1. Consult qualified electrician

2. Overloading motor. Too much water

delivery

2. Restrict outlet by closing down valve in discharge line

3. Liquid heavier and more viscous than

water

3. Consult factory

4. Seal binding

4. Replace

5. Rotor binding

5. Repair or replace

6. Voltage and frequency lower than rating

6. Reconnect to rated voltage and frequency

7. Defects in motor

7. Repair or replace

Pinholes in the casting.

Liquid drips around seal

area but is not seal

1. Cavitation caused by insufficient

inlet pressure or suction head (NPSH

Required)

1. Increase inlet pressure by adding a higher level of fluid

to source or increasing inlet pressure. (See Spec’s for

minimum NPSH Required)

2. If the available NPSH is not equal to, or greater than

that required by the pump, it must be increased. This

is usually done by increasing the static head, Hz.

NPSH FORMULAS

PROPOSED INSTALLATION

1. To calculate the NPSH available in a proposed

application, the following formula is recommended:

Hsv = Hp ± Hz - Hf - Hvp

2. Hsv-Available NPSH expressed in feet of fluid

3. Hp-Absolute pressure on the surface of the liquid

where the pump tanks suction, expressed in feet. This

could be atmospheric pressure or vessel pressure

(pressurized tank).

4. Hz-Static elevation of the liquid above, or below the

center line of the impeller, expressed in feet.

5. Hf-Friction and entrance head loss in the suction

piping, expressed in feet.

6. Hvp-Absolute vapor pressure of the fluid at the

pumping temperature, expressed in feet of fluid.