3 phase, 3 phase 1 phase – Flint & Walling Constant Pressure Pumping Stations - end suction centrifugal pumps User Manual

Page 4

4

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

SINGLE PHASE

Distance From Motor

To Fuse Box Meter,

or Electrical Outlet

Recommended Copper Wire Size

1HP

1-1/2 HP

2 HP

3 HP

5 HP

100 ft.

115V

230V

10

14

8

12

8

10

*

8

-

6

150 ft.

115V

230V

6

12

6

12

4

10

*

8

4

200 ft.

115V

230V

6

12

6

10

4

8

*

6

-

4

300 ft.

115V

230V

*

12

*

6

*

6

*

4

-

2

500 ft.

115V

230V

*

10

*

4

*

4

*

2

-

0

(*) Not economical to run at 115V, use 230V.

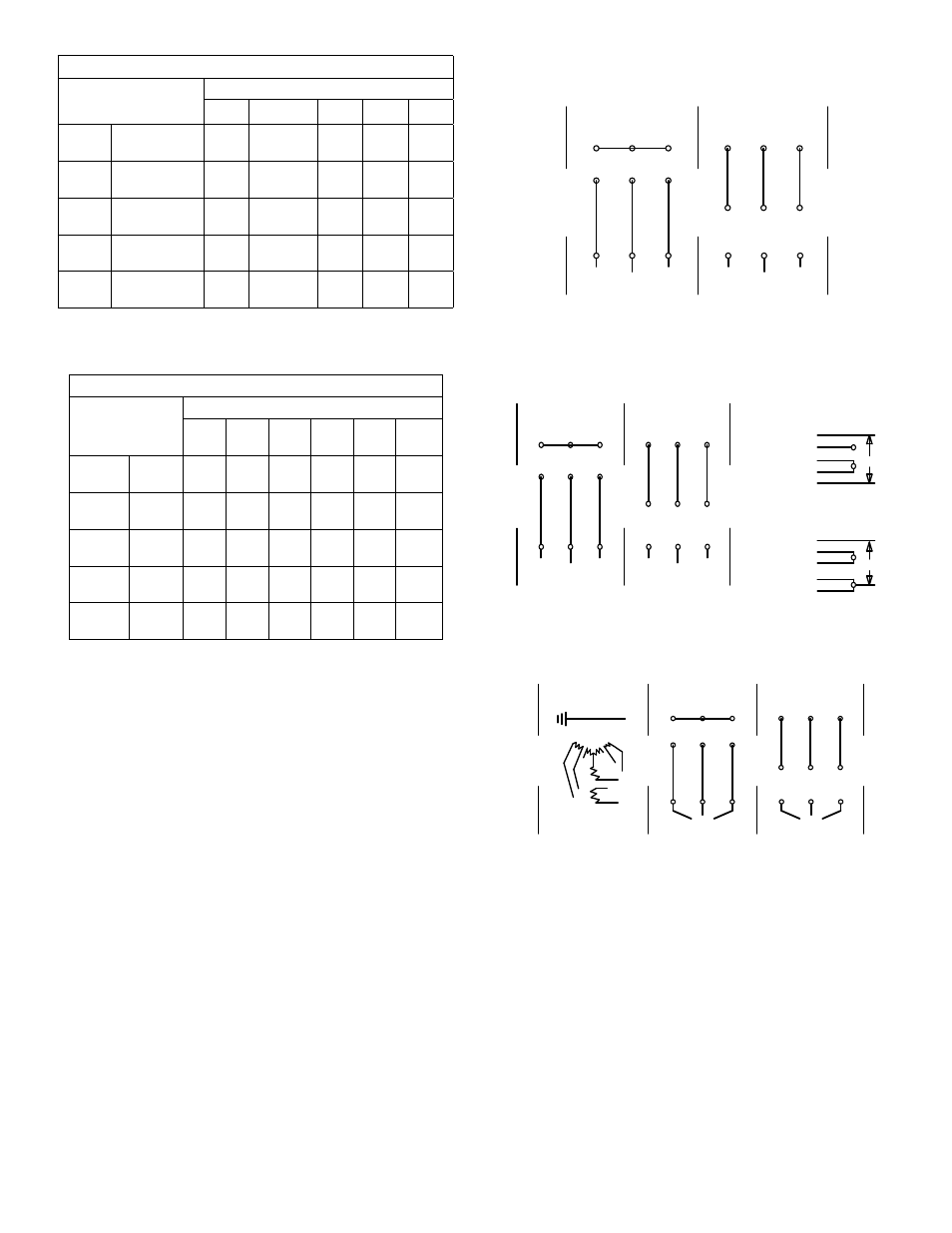

Figure 3

THREE PHASE

Distance From

Motor To Fuse

Box Meter, or

Electrical Outlet

Recommended Copper Wire Size

1HP

1-1/2

HP

2 HP 3 HP 5 HP

7-1/2

HP

100 ft.

230V

460V

14

14

12

12

12

12

12

12

10

12

8

12

150 ft.

230V

460V

14

14

12

12

12

12

10

12

8

12

6

12

200 ft.

230V

460V

14

14

12

12

12

12

10

12

8

12

6

12

300 ft.

230V

460V

12

14

12

12

10

12

8

12

6

10

4

10

500 ft.

230V

460V

10

14

10

12

8

12

6

10

4

8

2

8

Figure 4

MOTOR PROTECTION

WARNING: Never examine, make wiring changes

or touch the motor before disconnecting the main

electrical supply switch.

1.

Motors may or may not have built-in thermal

overload protection depending upon the

horsepower size, phase, type and motor

manufacturer. Refer to the motor nameplate for

overload protection information. It is recommended

that a properly sized magnetic or manual starter

(both with properly sized heaters) be used with all

motors. Install starters following instructions of the

starter manufacturer. See Figure 8 & 9 for magnetic

starter wiring diagram. See Figures 5, 6 & 7 for

motor diagrams.

2. All motors (single and three phase) should be

equipped with a correctly fused disconnect switch

to provide protection. Consult Local or National

Electrical Codes for proper fuse protection based on

motor nameplate.

3. Under size wiring can cause motor failure (low

voltage), frequent cut-out of motor overload

protector, television interference and even fire.

Make certain the wiring is adequately sized (Figure

3 & 4), well insulated and connected to a separate

circuit outside the building in case of fire.

IL1229

6

5

4

3

2

1

7

8

9

6

5

4

7

8

9

3

2

1

HIGH VOLTAGE

LOW VOLTAGE

LINE

LINE

3 Phase

Figure 5 - Wiring Diagram for Baldor TEFC 3 Phase

motors

6

5

4

3

2

1

7

8

9

6

5

4

7

8

9

3

2

1

(4)

(10)

(9)

(3)

(2)

(4)

(10)

(9)

(3)

(2)

IL1230

HIGH VOLTAGE

LOW VOLTAGE

HIGH VOLTAGE

LOW VOLTAGE

LINE

LINE

BROWN

LINE

VIOLET

BLACK

YELLOW

BLUE

BROWN

LINE

VIOLET

BLACK

YELLOW

BLUE

3 Phase

1 Phase

Figure 6 - Wiring Diagram for Franklin Electric TEFC 1 Phase

and 3 Phase motors

IL1231

T6

T5

T4

T3

T2

T1

T7

T8

T9

T6

T5

T4

T7

T8

T9

T3

T2

T1

T2

T5

T8

T6

T3

T7 T1

HIGH VOLTAGE

LOW VOLTAGE

GROUND

(WHEN REQ)

LINE

LINE

3 Phase

Figure 7 - Wiring Diagram for Marathon TEFC 3 Phase

motors