Dimensions in inches – Flint & Walling Constant Pressure Pumping Stations - end suction centrifugal pumps User Manual

Page 2

2

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

SUCTION LIMITATIONS

1. Units are non self-priming. Normally after being

primed the total suction lift of the pump is 15 feet.

2. Where liquids at or near their boiling points are

being handled, the supply must be located above

the suction, so that the available NPSH will be

greater than that required by the unit.

PIPING

1. Do not use the pump as support to the piping. The

pipe must be independently supported near the

pump so that no strains will be transmitted to the

unit. Failure to do so will cause premature pump

failure and will void the warranty.

2. Suction and discharge sizes are selected for proper

performance of the pumping unit and are not

intended to determine the suction and discharge

pipe sizes. Pipe sizes must be determined by the

user based on the system requirements.

3. Install both a union and a gate valve (not furnished)

on the suction and discharge side of the pump for

service convenience.

CAUTION: Do not use a globe or other restricting

type of valve at the discharge. Globe valves seriously

restrict the capacity of the pump.

4.

All joints and connections should have pipe sealing

compound (male threads only) applied and drawn

up tightly.

CAUTION: The entire system must be air and water

tight for efficient operation.

SUCTION PIPING

1. Suction piping should be short in length, as direct

as possible, and never smaller in diameter than the

pump suction opening.

2. Use galvanized piping, rigid plastic or other suitable

pipe that will not collapse under suction.

3. The suction pipe should slope upward to the pump

inlet. A horizontal suction line must have a gradual

rise to the pump. Any high point in the pipe will

become filled with air and thus prevent proper

operation of the pump. When reducing the piping

to the suction opening diameter use an eccentric

reducer with the eccentric side down to avoid air

pockets. Never use a straight taper reducer in a

horizontal suction line, as it tends to form an air

pocket in the top of the reducer and the pipe.

Valves in Suction Piping

1. If the pump is operating under static suction lift

conditions, a foot valve may be installed in the

suction line to avoid the necessity of priming each

time the pump is started.

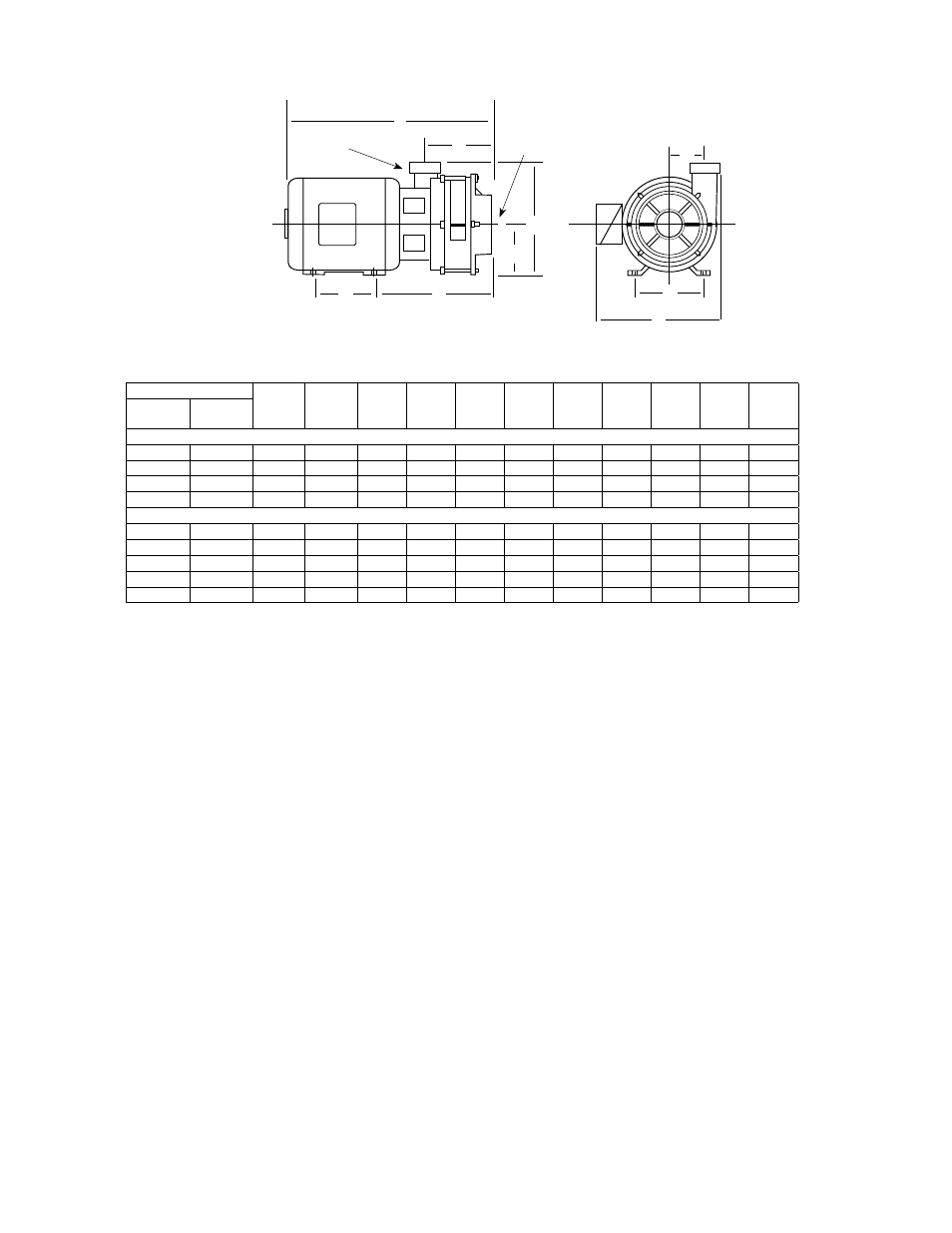

DIMENSIONS in INCHES

Figure 1

C22000 SERIES

Catalog Number

HP

Motor

Frame

Size

A

B

C

D

E

F

G

J

K

1 Phase 3 Phase

SINGLE STAGE 3500 RPM

C22131

—

3

182JM

4.50

7.50

10.24

4.50

10.81

4.06

12.12

19.49

3.44

—

C22133

3

145JM

5.00

5.50

9.49

3.50

9.81

4.06

10.50

17.87

3.44

C22151

—

5

184JM

5.50

7.50

10.24

4.50

10.81

4.06

12.12

20.49

3.44

—

C22153

5

182JM

4.50

7.50

10.24

4.50

10.81

4.06

12.12

20.49

3.44

TWO STAGE 3500 RPM

C22231

—

3

182JM

4.50

7.50

12.49

4.50

10.81

6.31

12.12

20.49

3.44

—

C22233

3

145JM

5.00

5.50

11.74

3.50

9.81

6.31

10.50

20.12

3.44

C22251

—

5

184JM

5.50

7.50

12.49

4.50

10.81

6.31

12.12

22.74

3.44

—

C22253

5

182JM

4.50

7.50

12.49

4.50

10.81

6.31

12.12

22.74

3.44

—

C22273

7-1/2

184JM

5.50

7.50

12.49

4.50

10.81

6.31

12.12

22.74

3.44

Dimensions shown above are approximate maximum dimensions for standard pumps equipped with open drip

proof motors.

J

IL1000

A

C

D

E

F

2” Discharge

3” Suction

K

B

G