Flint & Walling Constant Pressure Pumping Stations - end suction centrifugal pumps User Manual

Page 5

5

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

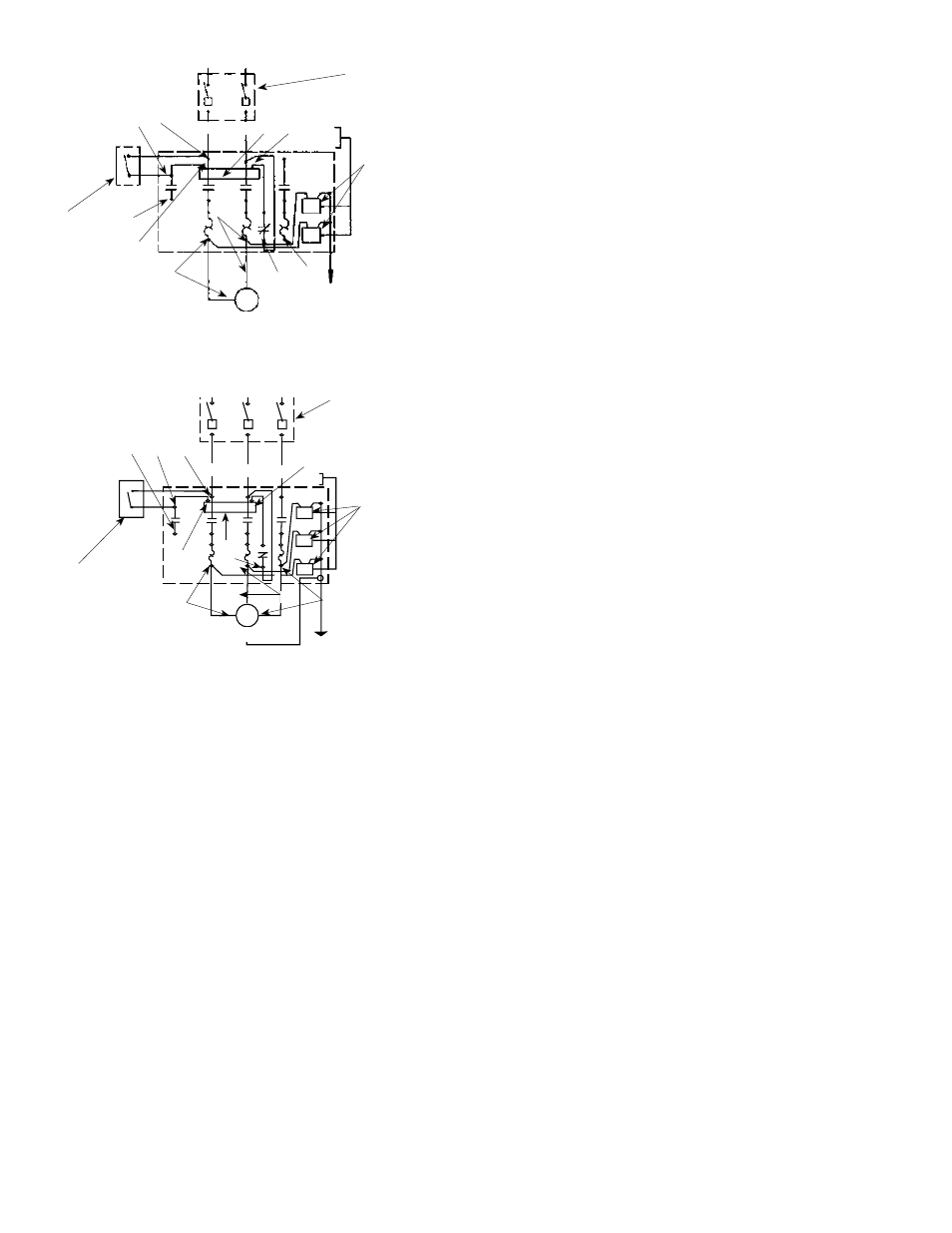

Figure 8

Warning: Connect

motor leads

momentarily for

correct rotation

Motor

Pressure

Switch

Magnetic Starter Wiring

Diagram - Single Phase

Fused

Disconnect

Switch

Lightning

Arrestors

#10 Or Heavier Copper Ground Wire,

Connect To 8 ft. Ground Rod Or Well Casing

L1

L2

3

2

1

V

M

W

T1

T2

T3

X2

IL0102

Figure 9

Pressure Switch

Magnetic Starter Wiring

Diagram - Three Phase

Fused Disconnect

Switch

Lightning

Arrestors

#10 Or Heavier Copper Ground Wire,

Connect To 8 ft. Ground Rod Or Well Casing

Motor

1

W

V

T3

X2

T2

T2

T1

M

L3

L2

L1

3

2

OPERATION

PRIOR TO STARTING

Before the pump is started initially, make the following

inspections:

• Check Rotation - Be sure that the pump operates in

the direction indicated by the arrow on the pump

casing, as serious damage can result if the pump

is operated with incorrect rotation. Rotation is

always counterclockwise facing the pump suction.

Operating the pump in reverse rotation may cause

extensive damage.

• Check all connections to motor and starting device

with wiring diagram. Check voltage, phase and

frequency on motor nameplate with line circuit.

ALL PUMPS WITH 3 PHASE MOTORS MUST BE

INSTALLED WITH A MAGNETIC STARTER WHICH

PROVIDES 3-LEG PROTECTION FOR MOTOR.

FAILURE TO USE CORRECT STARTER WILL VOID THE

WARRANTY.

PRIMING

1. Before starting any centrifugal pump it is absolutely

necessary that both the casing and suction pipe be

completely filled with liquid. This priming can be

accomplished by any of the following methods.

2. When the liquid supply level is above the center

line of the pump, it is primed by opening the

suction and discharge valves. The in flowing liquid

will displace the air and fill the suction line, pump

casing, and discharge line up to the level of supply.

3. Where the pump is operating with suction lift and

the suction line is equipped with a foot valve, the

system is filled with liquid by filling through the

discharge piping.

STARTING

1. Follow the steps below in the order indicated to start

pump:

• Close gate valve in discharge line.

• Open gate valve in suction line.

• Turn on power to pump motor.

2. When pump is operating at full speed, immediately

open the discharge gate valve slowly.

3. If the pump does not prime properly, or loses it

prime during start-up it should be shut-down and

the condition corrected before the procedure is

repeated.

NOTE: The gate valve in the discharge line should

always be closed when the pumps is started. The

excessive current required by the motor to start under

full load will in time cause motor trouble. A centrifugal

pump primed and operated at full speed with the

discharge gate valve closed usually requires much less

power than when it is operating at its rated capacity

and head with the discharge gate valve open.

OPERATING CHECKS

After initial start-up:

• Check the pump and piping to assure there are no

leaks.

• Check and record pressure gauge readings for

future reference.

• Check and record voltage, amperage per phase.

STOPPING PUMP

1. When stopping pump always close the discharge

valve first.

2. Pump should never run for any length of time with

both suction and discharge valves closed due to

danger of building up pressures and temperatures.

MAINTENANCE

LUBRICATION

The pump and motor requires no lubrication. The ball

bearings of the motor have been greased at the factory.

Under normal operating conditions they should require

no further greasing.

FREEZING

Drain the entire system if there is danger of freezing. A

drain plug is provided at the bottom of the pump case

for this purpose.