Flint & Walling Constant Pressure Pumping Stations - end suction centrifugal pumps User Manual

Page 6

6

95 North Oak Street • Kendallville, IN 46755

Copyright 2012. All Rights Reserved.

ROTARY SHAFT SEAL

The mechanical shaft seal should be replaced if water

is noticed around the motor shaft. Remove case and

impeller and, using two screw drivers to pry on each

side, remove seal stationary seat. Clean seat area of

frame, install new stationary seat with ceramic surface

facing out and slide new rotating element over shaft

sleeve with hard carbon surface against ceramic seat.

Be sure to keep all surfaces clean. Lubricating seal

parts with water will help the installation of the seal.

Reinstall impeller and pump case.

CAUTION: Make certain that the power supply is

disconnected before attempting to service the unit!

Failure to do so could result in personal injury or fatal

electrical shock.

MOTOR

Keep motor clean and dry. It is drip-proof when

installed horizontally and the windings are protected

from excess humidity, but extreme conditions should

be avoided when possible. If motor fails to run, be

sure power is on, all switches or electrical controls are

closed, fuses are in order and all electrical connection

are tight. (Motor must be repaired by Authorized

Repair Station under terms of guarantee.)

FAILURE TO PUMP

If the motor runs, but no water is pumped, be sure

pump is primed, that there are no air leaks in suction

piping, that all gate valves are open and all check valves

operate.

NET POSITIVE SUCTION HEAD (NPSH)

NPSH combines all of the factors limiting the suction

side of a pump; internal pump losses, static suction

lift, friction losses, vapor pressure and atmospheric

conditions. It is important to differentiate between

REQUIRED NPSH and AVAILABLE NPSH.

NPSH REQUIRED

REQUIRED NPSH is a factor designed into a pump and

measurable in the test laboratory by the manufacturer.

Testing facilities can determine losses in the suction

piping, static lift and barometric pressures.

NPSH AVAILABLE

1. The term for providing sufficient pressure on the

suction, at the impeller eye, to prevent “boiling” is

known as NPSH AVAILABLE. It is a function of the

pumping system and consists of pressure on the

liquid at its source, the elevation of the liquid with

respect to the impeller center line, losses in the

suction piping and vapor pressure of the liquid.

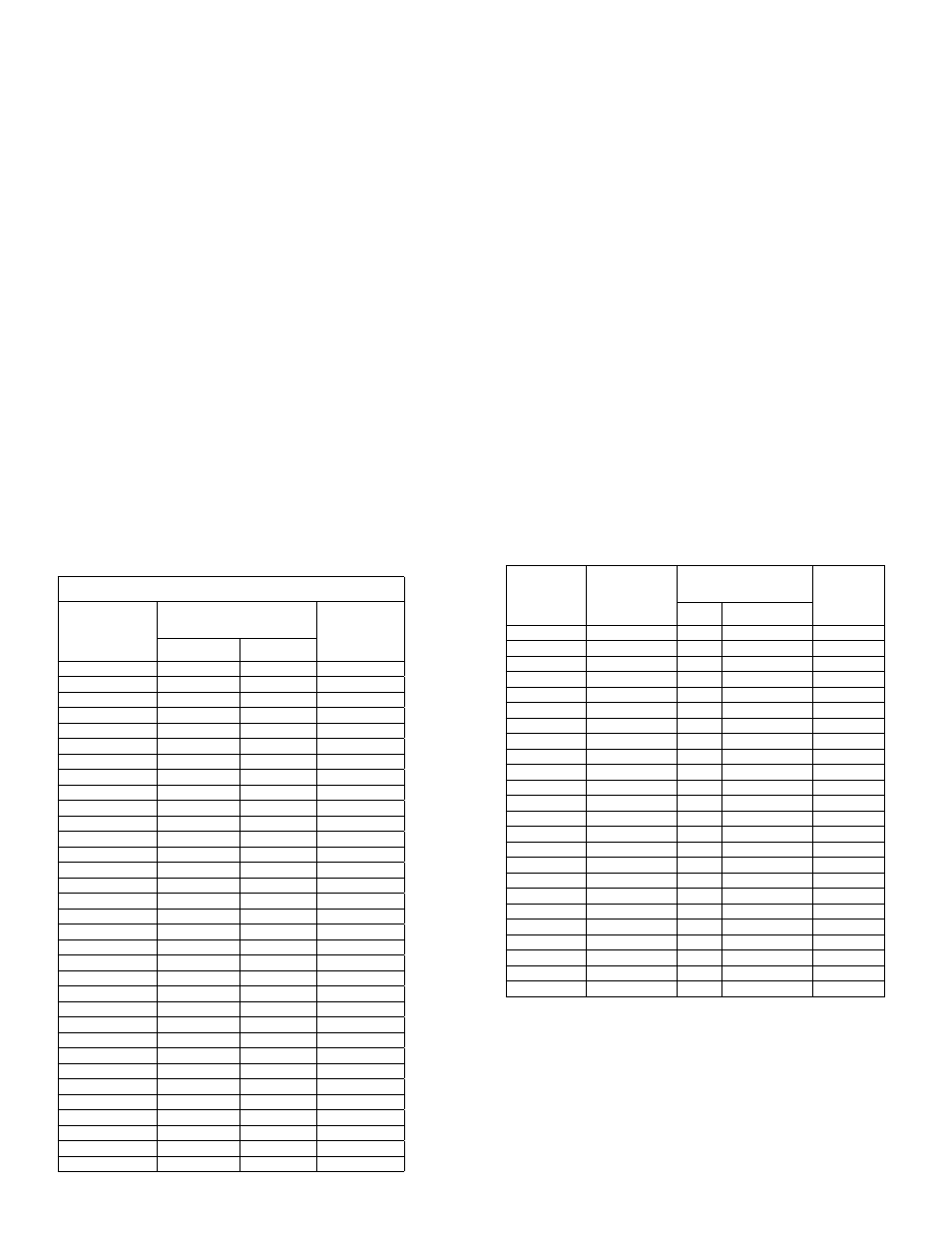

PROPERTIES OF WATER

Temperature

ºF

Absolute Vapor

Pressure

Specific

Gravity

PSI

Ft. Water

60

0.26

0.59

0.999

85

0.60

1.4

0.996

100

0.95

2.2

0.993

120

1.69

3.9

0.989

130

2.22

5.0

0.986

140

2.89

6.8

0.983

150

3.72

8.8

0.981

160

4.74

11.2

0.977

170

5.99

14.2

0.974

180

7.51

17.8

0.970

185

8.38

20.0

0.969

190

9.34

22.3

0.966

195

10.38

24.9

0.964

200

11.53

27.6

0.963

202

12.01

28.8

0.962

204

12.51

30.0

0.961

206

13.03

31.2

0.960

208

13.57

32.6

0.960

210

14.12

33.9

0.959

212

14.70

35.4

0.958

214

15.29

37.0

0.957

216

15.90

38.4

0.956

218

16.54

40.0

0.956

220

17.19

41.6

0.955

222

17.86

43.3

0.954

224

18.56

45.0

0.953

226

19.28

46.8

0.953

228

20.02

48.6

0.952

230

20.78

50.5

0.951

240

24.97

61.0

0.947

250

29.83

73.2

0.943

300

67.00

168.6

0.918

350

134.60

349.0

0.891

Altitude

(Feet)

Barometer

Inches

Mercury

Atmospheric

Pressure

Boiling

Point ºF

PSIA

(ft. water)

-1000

31.0

15.2

32.5

213.8

-500

30.5

15.0

34.6

212.9

0.0

29.9

14.7

33.9

212.0

+500

29.4

14.4

33.3

211.1

+1000

28.9

14.2

32.8

210.2

+1500

28.3

13.9

32.1

209.3

+2000

27.8

13.7

31.5

208.4

+2500

27.3

13.4

31.0

207.4

+3000

26.8

13.2

30.4

206.5

+3500

26.3

12.9

29.8

205.6

+4000

25.8

12.7

29.2

204.7

+4500

25.4

12.4

28.8

203.8

+5000

24.9

12.2

28.2

202.9

+5500

24.4

12.0

27.6

201.9

+6000

24.0

11.8

27.2

201.0

+6500

23.5

11.5

26.7

200.1

+7000

23.1

11.3

26.2

199.2

+7500

22.7

11.1

25.7

198.3

+8000

22.2

10.9

25.2

197.4

+8500

21.8

10.7

24.7

169.5

+9000

21.4

10.5

24.3

165.5

+9500

21.0

10.3

23.8

194.6

+10000

20.6

10.1

23.4

193.7

+15000

16.9

8.3

19.2

184.0