Flint & Walling SP Self-Priming Sprinkler Pump User Manual

Page 2

2

© Copyright 2014 Flint & Walling. All rights reserved.

PREPARATION

Before beginning installation of product, make

sure all parts are present. Compare parts

with package contents drawing. If any part is

missing or damaged, do not attempt to assemble

the product. Contact customer service for

replacement parts.

Estimated Installation Time: 2 hours.

Tools Required for Assembly:

Hacksaw

Pipe Wrenches (2)

Wire Strippers

Needle-Nose Pliers

Phillips Screwdriver

Wire Cutters

Adjustable Wrench

Parts Required For Assembly:

2” foot valve or 2” suction strainer with check

valve

2 in. Sched 40 PVC pipe

1-1/2 in. Sched 40 PVC pipe

2 in. MPT x 2 in. slip adaptor

1-1/2 in. MPT x 1-1/2 in. slip adaptor

1-1/2 in. pipe tee

1-1/2 in. slip x 1-1/4 in. FPT reducer bushing,

1-1/4 in. MPT plug

2 in. 90º pipe elbow

1-1/2 in. 90º pipe elbow

thread tape

1/4 in. electric wire strain relief

2-step PVC glue system (primer and sealer)

Thread paste.

Optional Parts For Assembly (not included):

1. Priming Plug with Pressure Gauge: Used

instead of a priming plug alone. Helps

determine if the pump is primed, indicates if

the pump is operating properly and what kind

of pressure is in the system when operating.

a. (1) 1-1/4 in. MPT x 1/2 in. FPT reducer

bushing

b. (1) 1/2 in. MPT x 1/4 in. FPT reducer

bushing

c. (1) 100 PSI pressure gauge

2. Unions: Used for easy removal of the pump

from the sprinkler system.

a. (2) 2 in. union

b. (1) 1-1/2 in. union

3. (1) 1-1/2 in. Ball Valve: Prevents back flow

of water from the sprinkler system when the

pump is removed from the system.

4. 1-1/2 in. Couplers: Quantity determined by

the total length of pipe used.

5. 2 in. Couplers: Quantity determined by the

total length of pipe used.

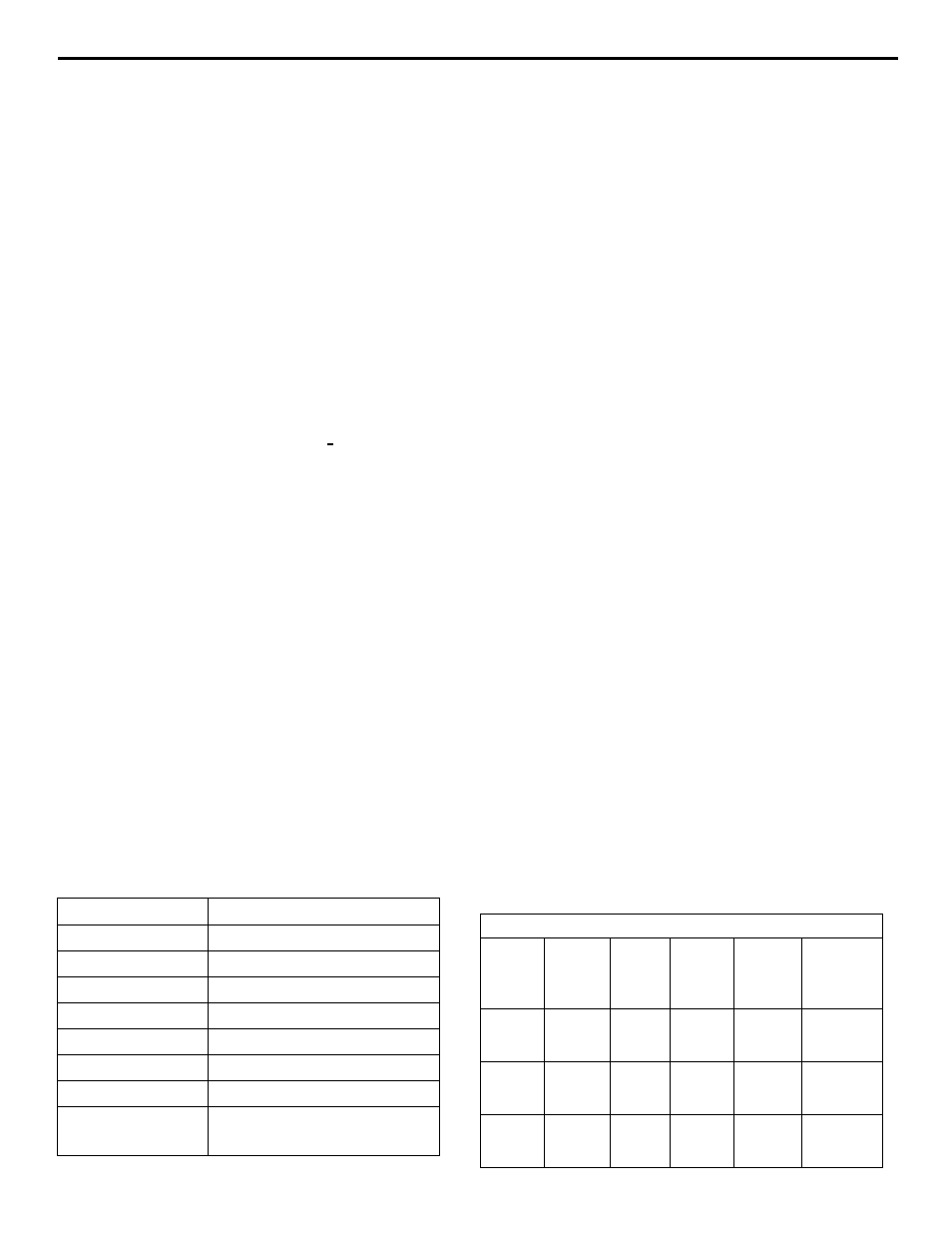

Component

Specifications

Pump housing

Heavy-duty, cast-iron

Diffuser

Thermoplastic

Impeller

Thermoplastic

Rotary seal

Carbon/silicon carbide

Mounting ring

Heavy-duty, cast-iron

Square cut ring

Buna-N

Base

Rigid steel

Motor

Dual voltage, double-ball

bearing

MOTOR DATA CHART

HP

Phase Volts

Code

Letter

Max

Amps

Locked

Rotor

Amps

1

1

1

115

230

H

17.6

8.8

62.0

31.0

1-1/2

1

1

115

230

G

18.00

9.00

72.0

36.0

2

1

1

115

230

G

21.00

10.50

108.0

54.0