Troubleshooting chart, Franklin three phase motor data — 60 hz, Symptom possible cause(s) corrective action – Flint & Walling 4 (10 cm) Stainless Commander Plus S Series User Manual

Page 8

14

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

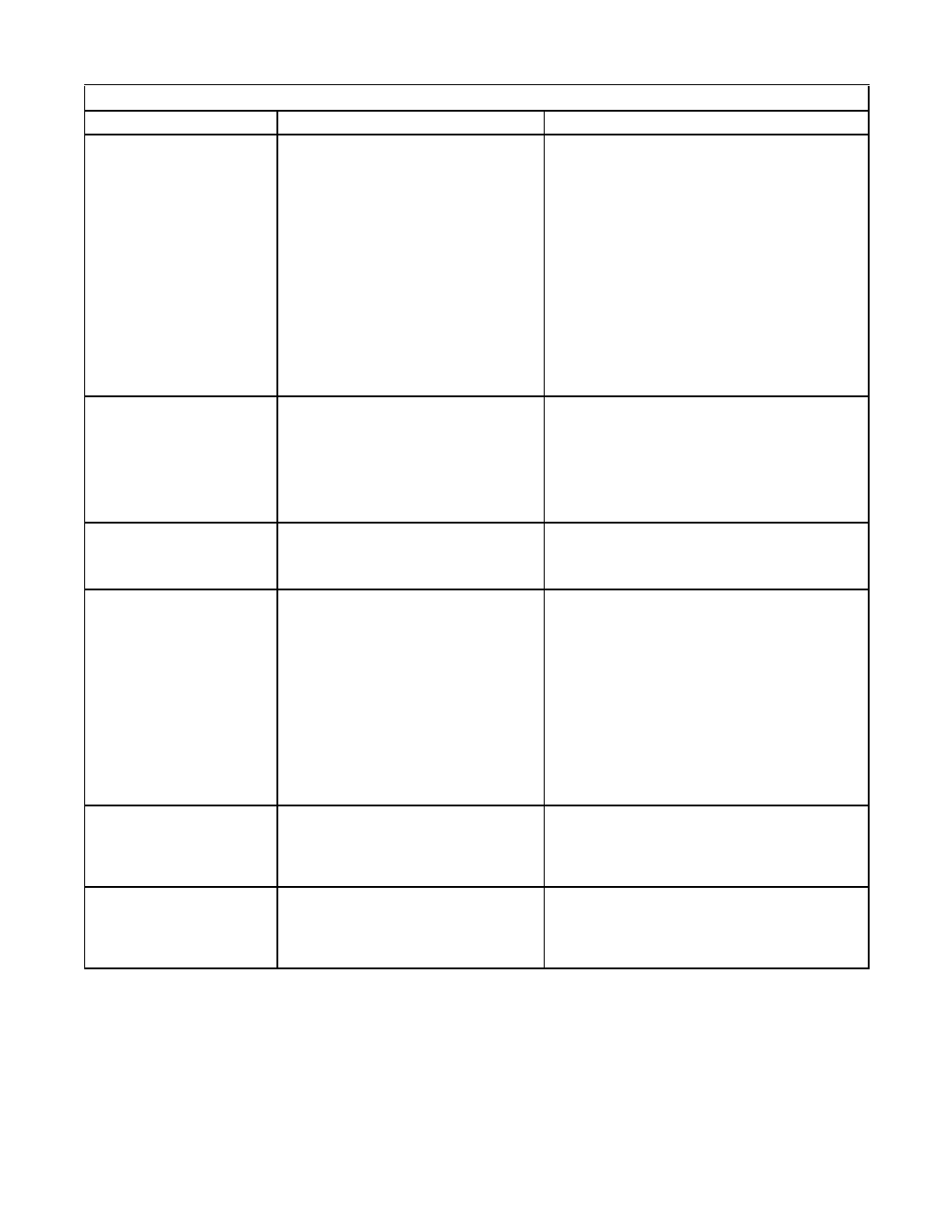

Troubleshooting Chart

Symptom

Possible Cause(s)

Corrective Action

Fuses blow when motor starts

1. Incorrect voltage

2. Incorrect fuses

3. Defective pressure switch

4. Control box malfunction

5. Bound pump

6. Defective cable or motor winding

7. Shorted or open motor winding

1. Contact power company if voltage is incorrect after

first checking for correct wire size. See Wire Size

Chart

2. Replace with proper fuses

3. Replace pressure switch or clean contacts

4. Correct faulty wiring or tighten loose contacts

5. Sand bound pump can sometimes be corrected

by temporarily reversing black and red leads in

control box then returning to normal. If pump does

not rotate freely, it must be pulled and cleaned or

realigned and the well condition corrected

6. The pump must be pulled and the cable

disconnected and inspected. Damaged cable

should be correctly spliced or replaced. If cable is

good, the motor winding is grounded

7. The pump must be pulled and motor or drop cable

repaired or replaced

Motor runs but fuses blow

1. Incorrect voltage

2. Overheated protectors

3. Improperly wired control box

4. Defective motor or cable

5. Defective pump

6. Defective installation

1. Contact power company in incorrect

2. Shade box, provide ventilation or move box away

from heat source

3. Rewire correctly

4. If ground, short or open circuit is indicated pump

must be pulled for repair

5. Pull pump, clean and repair

6. Pull pump, rechecking components and installation

Motor does not start and fuses

do not blow

1. No power

2. Defective pressure switch

3. Defective wiring

1. Replace fuses or reset circuit breaker. Contact

power company if no power is reaching box

2. Clean contact points or replace switch

3. Correct faulty wiring or connections

Pump runs, but delivers little or

no water

1. Air locked pump

2. Low water level in well

3. Pump rotation wrong

4. Check valve stuck or installed improperly

5. Leak in drop pipe

6. Pump screen locked

7. Worn pump

8. Loose or broken motor shaft

1. Normal delivery may resume if pump is started and

stopped at one minute intervals

2. Throttle pump delivery through restricting valve.

Lower pump setting if depth of well is adequate

3. Check wiring connections

4. Replace or reinstall properly

5. Raise pipe, check for leak and replace damaged

section

6. Clean screen and reset at less depth. It may be

necessary to clean well

7. Pull pump and replace worn impellers, casing or

other close fitting parts

8. Check for damaged shafts if coupling is loose and

replace worn or defective units

Pump keeps running

1. Pressure switch

2. Low level well

3. Leak in system

4. Worn pump

1. Clean points or replace switch

2. Throttle pump output or reset pump to lower level.

Do not lower if sand may clog pump

3. Replace damaged section

4. Pull pump and replace

Pump starts too often

1. Pressure switch

2. Leak in system

3. Check valve

4. Air supply (waterlogged tank - air under

pressure absorbed into the water)

1. Reset limit or replace switch

2. Repair or replace tank or pipes

3. Remove and replace if defective

4. Clean or replace. Drain and recharge tank

FRANKLIN THREE PHASE MOTOR DATA — 60 HZ

HP

Diameter Volts S.F.

Winding Resistance

(Ohms)

S.F. Load Current

(Amps)

Locked

Rotor Amps

KVA

Fuse Size

(Amperage)

Any 2 Leads

Running Under

Load Each Lead

STD

Dual

Element

1-1/2

4”

200

1.3

2.5 - 3.0

6.8

38.2

K

20

8

230

1.3

3.2 - 4.0

5.9

33.2

K

15

8

460

1.3

13.0 - 16.0

3.1

16.6

K

8

4

2

4”

200

1.25

1.8 - 2.4

9.3

53.6

L

25

11

230

1.25

2.3 - 3.0

8.1

46.6

L

25

10

460

1.25

9.2 - 12.0

4.1

23.3

L

11

5

3

4”

200

1.15

1.3 - 1.7

12.5

71.2

K

35

15

230

1.15

1.8 - 2.2

10.9

61.9

K

30

12

460

1.15

7.2 - 8.8

5.5

31.0

K

15

6

5

4”

200

1.15

.74 - .91

20.5

122.0

K

60

25

230

1.15

1.0 - 1.2

17.8

106.0

K

45

20

460

1.15

4.0 - 4.9

8.9

53.2

K

25

10

7-1/2

4”

200

1.15

.46 - .57

30.5

188.0

K

80

35

230

1.15

.61 - .75

26.4

164.0

K

70

30

460

1.15

2.5 - 3.1

13.2

81.9

K

35

15

5

6”

200

1.15

.77 - .93

20.0

99.0

H

50

25

230

1.15

1.0 - 1.2

17.6

86.0

H

45

20

460

1.15

3.9 - 4.8

8.8

43.0

H

25

10

7-1/2

6”

200

1.15

.43 - .53

28.3

150.0

H

80

35

230

1.15

.64 - .78

24.6

130.0

H

70

30

460

1.15

2.4 - 2.9

12.3

65.0

H

35

15

10

6”

200

1.15

.37 - .45

37.0

198.0

H

100

45

230

1.15

.47 - .57

32.2

172.0

H

90

40

460

1.15

1.9 - 2.4

16.1

86.0

H

45

20

15

6”

200

1.15

.24 - .29

54.5

306

H

150

60

230

1.15

.28 - .35

47.4

266

H

125

60

460

1.15

1.1 - 1.4

23.7

133

H

60

30

20

6”

200

1.15

.16 - .20

69.7

416

J

175

80

230

1.15

.22 - .26

60.6

362

J

175

70

460

1.15

.8 - 1.0

30.3

181

J

80

35

25

6”

200

1.15

.12 - .15

86.3

552

J

225

100

230

1.15

.15 - .19

75.0

480

J

200

90

460

1.15

.63 - .77

37.5

240

J

100

45

30

6”

200

1.15

.09 - .11

104.0

653

J

300

125

230

1.15

.14 - .17

90.4

568

J

250

100

460

1.15

.52 - .64

45.2

284

J

125

50

40

6”

460

1.15

.34 - .42

61.6

397

J

175

70

50

6”

460

1.15

.25 - .32

77.0

414

H

200

90

60

6”

460

1.15

.22 - .27

91.0

518

H

250

100

75

6”

460

1.15

.10 - .13

107

864

L

300

125

100

8”

460

1.15

.07 - .09

142

1211

L

400

175