Flint & Walling 4 (10 cm) Stainless Commander Plus S Series User Manual

Page 5

8

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

9

Copyright © 2014. All rights reserved • 95 North Oak St. • Kendallville, IN 46755

IL0100

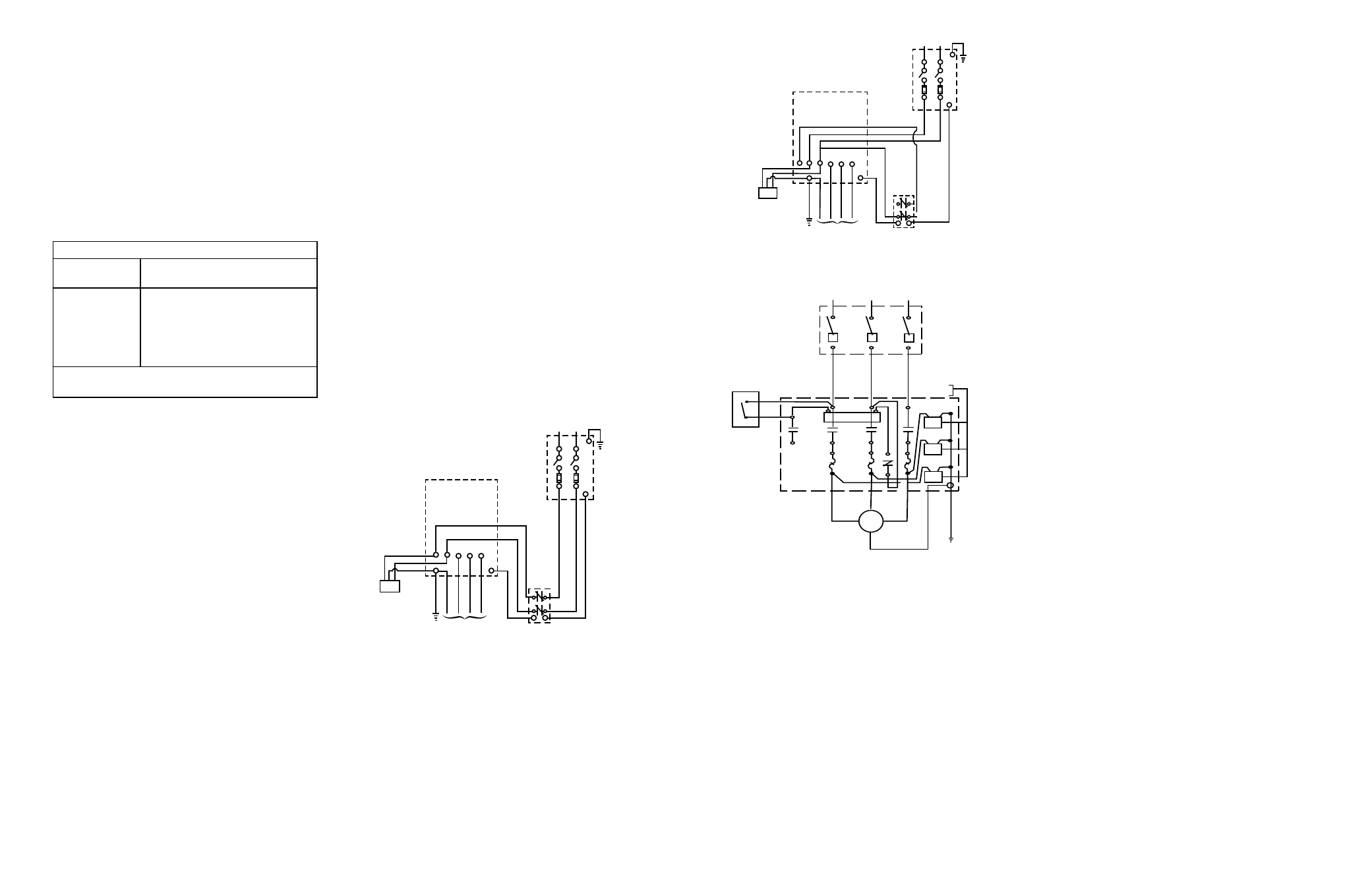

Fused Disconnect

Switch

Ground

Pressure

Switch

Ground

L1 L2

R Y B

Control Box

To Motor

Ground

Red

Yellow

Black

Lightning

Arrestor

SW

Figure 10 —

Single Phase Control Box with Contactor

IL0102

Pressure

Switch

3

2

L1

L2

L3

Fused Disconnect

Switch

Lightning

Arrestors

V

M

W

T1

T2 X2

T3

Motor

Ground

T3

T1

Figure 11 — Three Phase Magnetic Starter

1. For proper sizing of fuses for fuse disconnect box,

see Motor Data Charts. Improperly sized fuses will

result in fuses blown or circuit breakers tripped.

GROUNDING

Proper Grounding of Submersible Motors

1. The purpose of grounding any electrical apparatus is

to prevent an electrical shock hazard if exposed metal

becomes connected to an electrical circuit. This can

occur from a defect in construction of the electrical

equipment, physical damage, or a breakdown in the

insulation of the equipment. Grounding prevents

shock hazard by keeping exposed metal from

reaching a voltage level which could endanger

anyone coming in contact with the electrical

equipment. Fault current is “drained” by the ground

conductor, and if the fault is severe enough, the

circuit will be opened by the fuse or circuit breaker.

2. The U.S. National Electrical Code (NEC) requires that

motor-operated water pumps, including submersible

type regardless of voltage, shall be grounded. The

Canadian Electrical Code specifically discusses

grounding requirements for submersible pumps.

Interpretation of these and other codes may vary

in different states and localities, but all applicable

national, state, and local codes should always be

followed.

3. Any submersible motor which is to be run tested out

of the well should be grounded to prevent possible

shock hazard during the test.

NOTE: Always disconnect all power when making

ohmmeter check and while pulling or installing a pump.

4. The most logical way to “frame” ground a submersible

motor is normally as follows:

a. Run an extra wire with the motor power conductors.

This wire must be sized to meet Table 250-95 in the

U.S. National Electrical Code. If code information

is unavailable, using the same size wire as the

power conductors is normally adequate.

b. The ground wire may be insulated or bare. If

insulated, it must be green with or without yellow

stripe(s). The ground wire may be part of, or

separate from the supply cable. It may be

continuous or spliced above the pump along with

the supply cable.

c. Connect the green or bare ground wire to the

green ground wire of the submersible motor lead

assembly. If the lead wire assembly does not

include a separate ground wire, attach a lug to

the ground wire and place the lug over one of the

motor studs above the pump intake flange so the

pump will not be cocked. The ground lug will then

be secured with the nut which holds the pump on

the motor.

d. Connect the other end of the ground wire to the

power supply grounding terminal or to the control

panel ground bar if it is connected to the power

supply ground.

e. All connections should be tight and corrosion

resistant, including screws, lugs or clamps.

Grounding Control Boxes

1. It is recommended the control box grounding terminal

always be connected to circuits which include a

grounding conductor. In fact, this is a requirement

of the National Electrical Code. If the circuit has no

grounding conductor and no metal conduit from the

box to supply panel, use a wire at least as large as

line conductors and connect from supply panel to the

control box and to the motor lead ground wire.

WARNING: Failure to ground the box frame can result in a

fatal electrical shock hazard if a circuit fault occurs.

WARNING: Serious or fatal electrical shock may result

from failure to connect all metal plumbing, and the motor

if outside a drilled well, to the power supply grounding

terminal with wire no smaller than motor cable wires. Do

not use motor in swimming area.

8. Lower the pump into the well slowly without forcing.

Use a vise or foot clamp to hold the pipe while

connecting the next length. A boom, tripod or

pump setting rig is recommended. Lower pump to

approximately 10 feet below maximum draw down

of the water if possible and keep approximately 10

feet from the bottom. DO NOT set pump on bottom

of well. Before each new length of pipe is added,

attach the coupling to the top of the pipe length. This

will provide a stop for the foot clamp to hold while the

next section of pipe is being installed.

9. On a standard tank with an air volume control a

bleeder orifice is required. Install the bleeder orifice

in the discharge pipe 5 feet or more below the snifter

valve. See Figure 2 and the table below.

Distance Table

Tank Size

Gallons

Depth From Horizontal Check

Valve To Bleeder Orifice

42

82

120

220

315

525

5

10

15

15

20

20-35

Installations that use a pre-charged pressure tank

do not require a bleeder orifice.

WELL SEAL/PITLESS ADAPTER INSTALLATION

1. All installations should have a well seal. Make sure

the seal is seated and tighten the bolts evenly.

NOTE: Be sure to assemble the tee to the pipe above

the well seal to prevent dropping the pipe and pump

down the well as you lower it.

IMPORTANT: Well seal and piping must be protected

from freezing.

2. On a pitless adapter installation, the connection to the

system supply line is made below ground. Install the

pitless adapter following the instructions included with

particular brand or design being used in the installation.

NOTE: Follow ALL applicable state and local plumbing

codes.

PRELIMINARY TEST RUN

1. When pump is at desired depth, install throttle valve

for preliminary test run. Wire single phase motors

through the control box, following instructions in box

regarding color coding of wires, etc. Wire 3-phase

motors through a magnetic starter. Test cable for

continuity with an ohmmeter.

2. With pump discharge throttled, run pump until water

is clear of sand or any other impurities. Gradually

open discharge.

CAUTION: Be sure you do not stop pump before water

runs clear. This may take several hours. If pump stops

with sand in it, it will lock.

3. If pump lowers water in the well far enough to lose

prime, either lower pump in the well (if possible) or

throttle discharge to capacity of the well.

4. If well is low capacity, use a low water level control.

5. On 3-phase units, establish correct motor rotation

by running in both directions. Change rotation by

exchanging any two of the three motor leads. The

rotation that gives the most water flow is always the

correct rotation.

PRESSURE TANK INSTALLATION

1. On a new installation, install the pressure tank along

with the pressure switch, pressure gauge, pressure

relief valve, check valve, gate valves and unions as

shown in Figures 1 & 2.

2. On replacement pump installations be sure that the

tank system is in good operating condition, as a

water logged tank may cause pump failure.

ELECTRICAL HOOK-UP

WARNING: Since most submersible pump problems are

electrical, it is very important that all electrical work be

done properly. Therefore, all electrical hook-up work

or electrical service work should be done by a qualified

electrician or serviceman only!

WARNING: Always disconnect power source before

working on or near motor, its connected load or control

box and wiring. If the power disconnect is out of sight,

lock it in the open position and tag to prevent unexpected

application of power.

1. Proceed with electrical hook-up matching cable colors

and following the wiring diagrams (Figures 9, 10 &11)

or inside the lid of the control box.

WARNING: Connect motor leads momentarily for correct

rotation before installing pump in well.

FUSE SIZES

Fused Disconnect

Switch

Ground

Pressure

Switch

Ground

L1 L2

R Y B

Control Box

To Motor

Ground

Red

Yellow

Black

Lightning

Arrestor

IL0100

Figure 9 — Single Phase Control Box