9 maintenance and care, 10 disassembly, 11 troubleshooting – Festo DAPS..R..-F.. User Manual

Page 4: 12 technical data

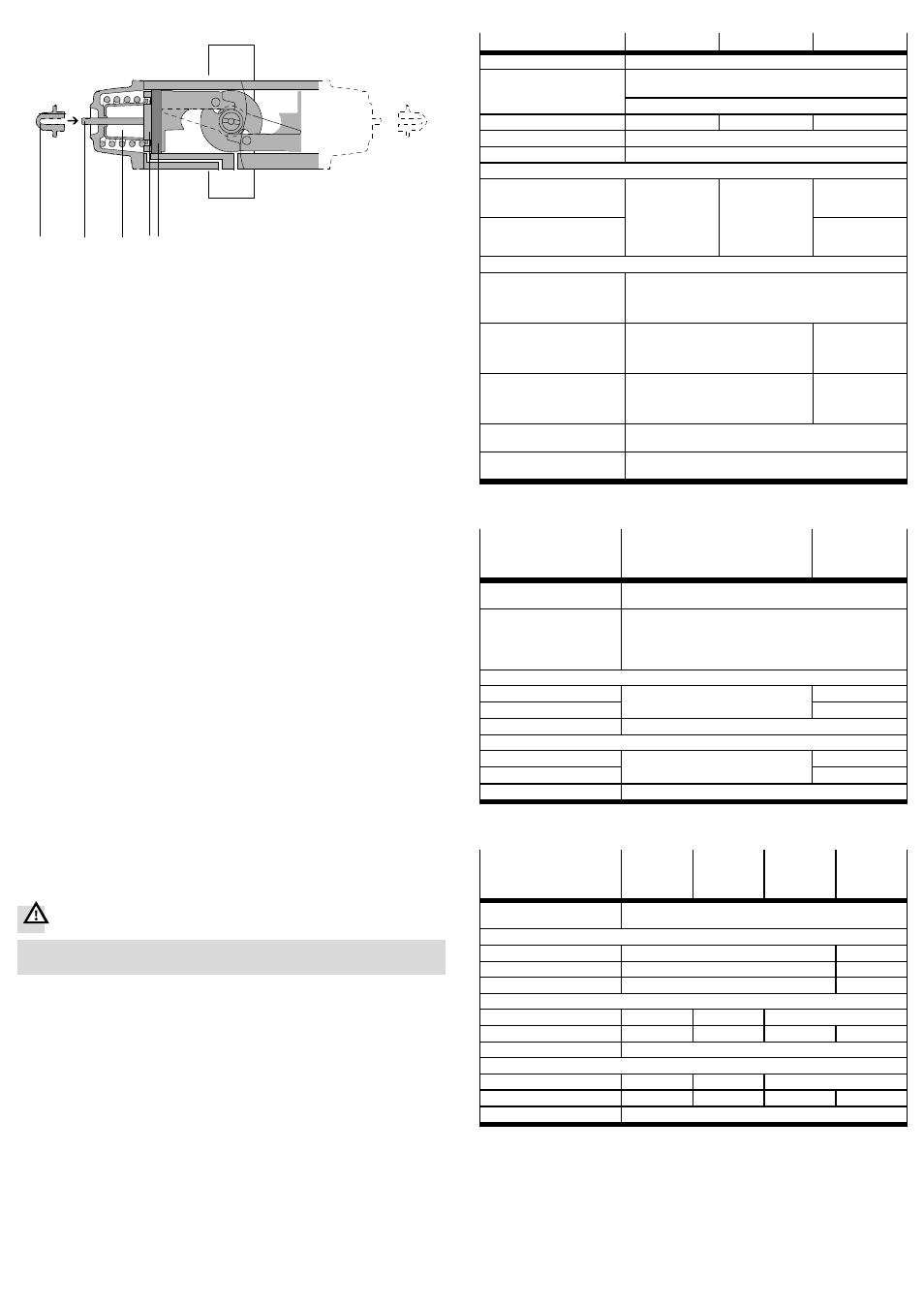

End position for left turning – opening process valve

1

2

3 4

5

1 Lock nut with sealing ring

2 Threaded rod

3 Adjustment range of the outer end

position (see technical data)

4 Spring disc

5 Piston

Fig. 10

1. Supply compressed air and open the process valve. The pistons move to the

outer end position. This fixes the threaded rods, if necessary – dependent on the

current setting. Loosening of the lock nuts will then not accidentally change the

current setting.

2. Screw down the lock nuts with sealing ring on both sides. If the threaded rods

have loosened, retighten them by hand until a light resistance is felt.

3. Vent the DAPS and close the process valve. The pistons move to the inner end

position.

4. Adjust the end position:

Observe that a complete turn of the threaded rod can change the swivel angle

approx. 1.5° to 3.5° – dependent on the product design.

– Turning threaded rods clockwise reduces the swivel angle.

– Turning threaded rods anti-clockwise increases the swivel angle.

• Turn both threaded rods equally far so they stop the pistons in operation

simultaneously.

5. Supply compressed air and open the process valve. The pistons run against the

threaded rods into the outer end position.

6. Check the position of the process valve. To change the swivel angle, repeat

steps 3 to 6

7. If the desired position is found, check whether both threaded rods offer resist-

ance to the pistons in the opened process valve position. If necessary, screw in

loose threaded rods carefully until resistance is felt.

8. Screw the lock nuts back onto the threaded rods – tightening torque 5 Nm.

9. Check the mode of operation of the quarter turn actuator (

section 8.4)

8.4 Check the mode of operation of the quarter turn actuator

• Check in cyclical tests, through alternating pressurisation and, if necessary,

venting, whether the quarter turn actuator takes the required positions.

• If necessary, adjust the end positions to the extent the quarter turn actuator

offers this possibility (

section 8.1).

9

Maintenance and care

If used as intended in the operating instructions, the device will be maintenance-

free.

10

Disassembly

Warning

Danger of injury due to uncontrolled movements.

• Switch the tubing system pressureless before dismantling.

1. If necessary, remove any existing limit switches.

2. Remove the pneumatic switching valve.

3. Loosen the screws on the flange of the process valve.

4. Remove the quarter turn actuator (if necessary including mounting adapter and

coupling extension) from the process valve.

11

Troubleshooting

• Please contact Festo.

12

Technical data

General technical data

DAPS-...

DAPS–...–T6

DAPS–...–CR

Operating medium

Compressed air to ISO8573-1:2010 [7:4:4]

Note about the

operating medium

Operation with lubricated medium possible (required in further

operation)

Ester oil < 0.1 mg/m³, corresponds to ISO 8573:2010 class [-:-:2]

Ambient temperature

[°C]

–20 … +80

–50 … +60

–20 … +80

Swivel angle

[°]

90

Mounting position

Any

Valve connection corresponding to standard

– DAPS-0008-…

– …

– DAPS-0030-...

VDI/VDE 3845

(NAMUR)

VDI/VDE 3845

(NAMUR)

–

– DAPS-0053-…

– …

– DAPS 8000

VDI/VDE 3845

(NAMUR)

Pneumatic connection

– DAPS-0015..RS to

DAPS-0180..RS..

– DAPS-0008..R- to

DAPS-0360..R-..

G1/8

– DAPS-0240..RS to

DAPS-0960..RS..

– DAPS-0480..R- to

DAPS-1920..R-..

G1/4

G1/8

– DAPS-1440..RS to

DAPS-4000..RS..

– DAPS-2880..R- to

DAPS-8000..R-..

G3/8

–

Standard connection

to the process valve

ISO 5211

CE marking (see declaration of

conformity

www.festo.com)

in accordance with EU Explosion Protection Directive (ATEX)1)

1)

Certification-specific special documentation and the documentation of the sensors must be considered

www.festo.com

Operating conditions

DAPS..RS-…

(single-acting)

DAPS-

0015 … 0960

DAPS-

1440 … 4000

Nominal operating

pressure

[bar]

5.6

Operating pressure

1)

– DAPS..RS1-...

– DAPS..RS2-...

– DAPS..RS3-...

– DAPS..RS4-...

[bar]

2.8 ... 8.4

3.5 ... 8.4

4.2 ... 8.4

5.6 ... 8.4

End-position adjusting range at 0°

– DAPS..RS-...

[°]

One end position adjustable; -1 … +9

±5

– DAPS..RS-...-T6

[°]

±5

– DAPS..RS-...-CR

[°]

–

End-position adjusting range at 90°

– DAPS..RS-...

[°]

One end position adjustable; 81 … +91

85 … +95

– DAPS..RS-...-T6

[°]

85 … +95

– DAPS..RS-...-CR

[°]

–

1)

Minimum operating pressures vary for single-acting quarter turn actuators dependent on the number of

springs

Operating conditions

DAPS..R-...

(double-acting)

DAPS-

0008

DAPS-

0015 …

1920

DAPS-

2880 …

5760

DAPS-

8000

Nominal operating

pressure

[bar]

5.6

Operating pressure

1)

– DAPS..R-...

[bar]

1 ... 8.4

1 ... 7

– DAPS..R-...-T6

[bar]

3.5 ... 8.4

–

– DAPS..R-...-CR

[bar]

2.5 ... 8.4

–

End-position adjusting range at 0°

– DAPS..R-...

[°]

–

-1 … +9

±5

– DAPS..R-...-T6

[°]

–

-1 … +9

±5

–

– DAPS..R-...-CR

[°]

–

End-position adjusting range at 90°

– DAPS..R-...

[°]

–

–

85 … +95

– DAPS..R-...-T6

[°]

–

–

85 … +95

–

– DAPS..R-...-CR

[°]

–

1)

Exceptions for devices with special marking