7 installation, 1 mechanical installation, 2 pneumatic installation – Festo DAPS..R..-F.. User Manual

Page 2: Connections for the compressed air supply

• Take into consideration the ambient conditions at the location of use. Corrosive

environments reduce the service life of the product.

• Remove the packaging except for the adhesive labels on the compressed air

supply ports (danger of contamination). The material used in the packaging has

been specifically chosen for its recyclability (exception: oil paper = residual

waste).

• Use the product in its original status, without any unauthorised product modific-

ations.

• Protect the device from pressure fluctuations. Use excess-pressure and pres-

sure-regulating valves.

• Make sure the compressed air is properly prepared (Technical data

section 12).

• Before carrying out installation, dismantling and maintenance work, switch off

the compressed air supply and vent the actuator. Secure compressed air supply

against accidental restarting.

Danger

In the case of single-acting DAPS, high spring forces (mechanically stored en-

ergy) are at work inside the product.

Parts can be ejected and cause serious personal injuries if the end cap is dis-

mounted.

• Never remove the end cap!

• Return the product to Festo if defective or for service.

Note

• Use only unlubricated compressed air under normal conditions.

The DAPS quarter turn actuator possesses an initial lubrication which suffices

for the complete service life.

Note

Continuous operation at the limits of the specified ambient temperature and

work frequency can reduce the service life of the quarter turn actuator.

• Use lubricated compressed air for continuous operation under extreme con-

ditions. The oil must be chemically inert and must not carbonise.

If lubricated compressed air is used:

The initial lubrication will be washed out. The quarter turn actuator may then

only be operated with lubricated compressed air.

7

Installation

Note

The following instructions on fitting the DAPS quarter turn actuator onto a pro-

cessing valve may only be used if the following requirements are met:

– The quarter turn actuator is installed in the direction of the tubing.

– If a 2-way process valve is used:

The 2-way process valve is closed.

– If a 3-way process valve is used:

The switching status of the 3-way process valve is known.

Note

If a 3-way processing valve is used:

• Align the quarter turn actuator so that the port openings for a NAMUR valve

face the side without tubing.

Note

Outflowing processing medium must not ingress into the quarter turn actuator.

The housing of some quarter turn actuators has a leakage groove on the process

valve port side. If the processing valve leaks, the leakage can flow through the

open groove.

• For housings with leakage grooves, make sure that the groove (

Fig. 1,

9 )

is not sealed. In this way you can be sure that neither processing medium nor

escaping air from the processing valve can penetrate into the quarter turn

actuator.

The DAPS quarter turn actuator can be mounted with or without an adapter bridge.

If there are high media temperatures in the tubing and in processing valve:

• Use an adapter bridge and also a heat-insulated coupling extension.

7.1 Mechanical installation

• In order to mount the DAPS quarter turn actuator, set the switching shaft of the

process valve so that the desired operating method for opening and closing the

process valve is implemented.

• Note that a processing valve with butterfly valve can only be opened in one dir-

ection and closed in the opposite direction.

• Observe the tightening torque

Thread

M5

M6

M8

M10

M12

M14

M16

M20

Tightening torque

[Nm]

5 …

6

10 …

11

20 …

23

45 ...

50

80 …

85

125 …

135

190 …

200

370 …

390

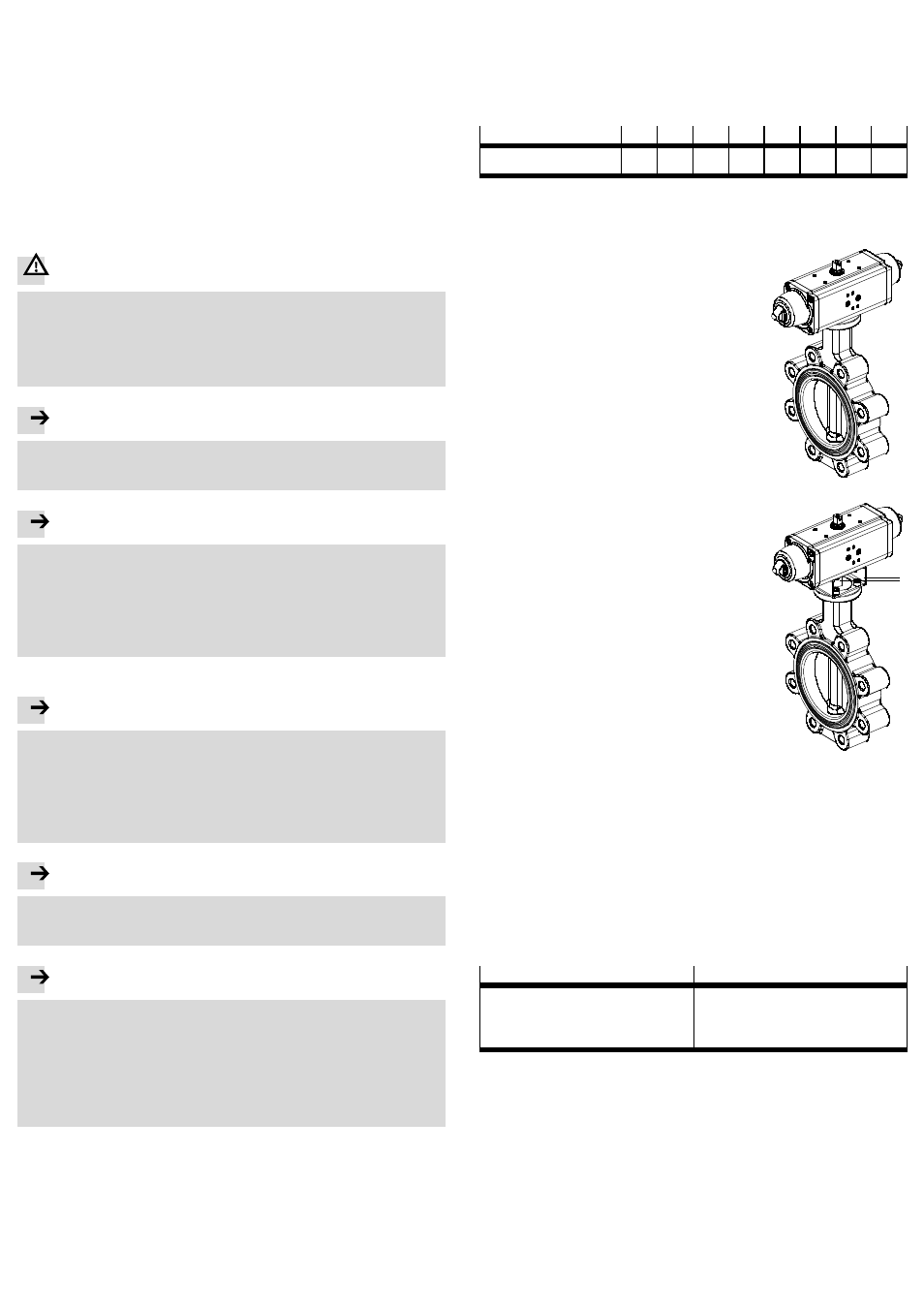

Fig. 5

To mount the quarter turn actuator without an adapter

bridge:

1. Place the quarter turn actuator on the switching

shaft of the process valve. Make sure here that the

square of the processing valve sits in the

star-shaped coupling of the quarter turn actuator

without being tilted.

Fig. 6

2. Fasten the quarter turn actuator with 4 corrosion-

resistant screws and retaining rings (material: VA)

to the connection flange of the process valve.

3. Tighten all the screws in diagonally opposite

sequence. Tightening torque

Fig. 5.

4. Continued

Point 6.

To mount the quarter turn actuator with an adapter

bridge, you need:

Fig. 7

1

2

– an adapter bridge (

Fig. 7,

1 ),

– a shaft extension (

Fig. 7

2 ).

1. Align the adapter bridge so that its supports are

oriented in the direction of the longitudinal axis of

the quarter turn actuator and, if necessary, the

open side of the adapter bridge towards the pro-

cess valve.

2. Fasten the adapter bridge to the quarter turn actu-

ator. But do not tighten the screws yet.

3. Guide the shaft extension through the adapter

bridge into the star-shaped coupling on the

bottom of the quarter turn actuator. Make sure

that the shaft extension sits in the coupling

without being tilted.

4. Fasten the quarter turn actuator with adapter bridge and shaft extension to the

connection flange of the process valve. Make sure here that the square of the

process valve sits in the shaft extension without being tilted.

5. Tighten all the screws in diagonally opposite sequence.

Tightening torque

Fig. 5.

After attachment of the quarter turn actuator:

6. Check in cyclical tests whether the quarter turn actuator turns in the required

direction of rotation and whether the process valve takes the required position.

7. If the quarter turn actuator does not turn in the required direction of rotation:

Carry out the following modification:

DAPS..R-… (double-acting)

DAPS..RS-… (single-acting)

1. Remove the pneumatic solenoid valve.

2. Turn the solenoid valve 180°.

3. Note the position of the threaded pin for

orientation of a NAMUR valve.

4. Fasten the solenoid valve again.

1. Remove the screws on the actuator side.

2. Turn the actuator 90° while it is still connec-

ted through the shaft extension or directly to

the processing valve.

3. Tighten the mounting screws.

7.2 Pneumatic installation

Connections for the compressed air supply

DAPS quarter turn actuator, double-acting:

– Air supply at port 2 (A) – see Fig. 1,

2

Rotational movement of the switching shaft in an anti-clockwise direction.

– Air supply at port 4 (B) – see Fig. 1,

4

Rotational movement of the switching shaft clockwise.

DAPS quarter turn actuator, single-acting (spring return):

– Air supply at port 4 (B): rotational movement anti-clockwise.

– Spring return: rotation clockwise.