Operating instructions safety monitors sfm – EUCHNER SFM-xxx User Manual

Page 3

Operating Instructions Safety Monitors SFM-...

These operating instructions are valid only

in combination with the manual of the safety

monitor and the manual for the configuration

software!

You will find this documentation on the CD

with the ASiMon configuration software or at

www.EUCHNER.de.

Correct use

EUCHNER SFM‑... series safety monitors monitor

all safety‑related bus users on the AS‑Interface bus

Safety at Work. A machine is put into the safe state

via the safety outputs of the safety monitors.

In this application, the safety monitor performs

a personal protection function.

Correct use includes compliance with the relevant re‑

quirements for installation and operation, for example

f

EN ISO 13849‑1, safety related parts of control

systems

f

EN 60 204‑1, electrical equipment of machines

f

IEC 62061, Safety of machinery ‑ Functional safety

of safety‑related electrical, electronic and program‑

mable electronic control systems.

Safety precautions

Safety monitors perform a personal protection func‑

tion. Incorrect installation or manipulation can lead

to severe injuries to personnel.

A complete safety‑oriented system generally

consists of several signalling devices, sensors

and evaluation units. The manufacturer of a

machine or installation is responsible for correct

and safe overall function.

The monitor is classified in Category 4 accord‑

ing to EN ISO 13849‑1. The classification of the

overall machine depends on the classification of

the bus users and the connection of the outputs.

Configuration must be password protected, and

the configuration log must be printed and signed.

All safety precautions and specifications in the

manual of the AS‑Interface safety monitor used

and in the manual for the configuration software

must be observed.

Functioning

When used correctly, EUCHNER SFM‑... series safety

monitors allow the operation of sensor‑controlled per‑

sonal protection equipment and other safety compo‑

nents as AS‑interface slaves in all categories up to and

including Category 4 according to EN ISO 13849‑1.

The safety monitor also performs the EMERGENCY‑

STOP function (stop category 0 or 1), which is manda‑

tory for all machines that are not manually controlled,

including dynamic monitoring of the restart function

and the contactor‑monitoring function.

The machine is put into the safe state via the safety

outputs of the safety monitor.

The AS‑Interface safety monitor is appropriately

configured using configuration software (refer to the

configuration software manual).

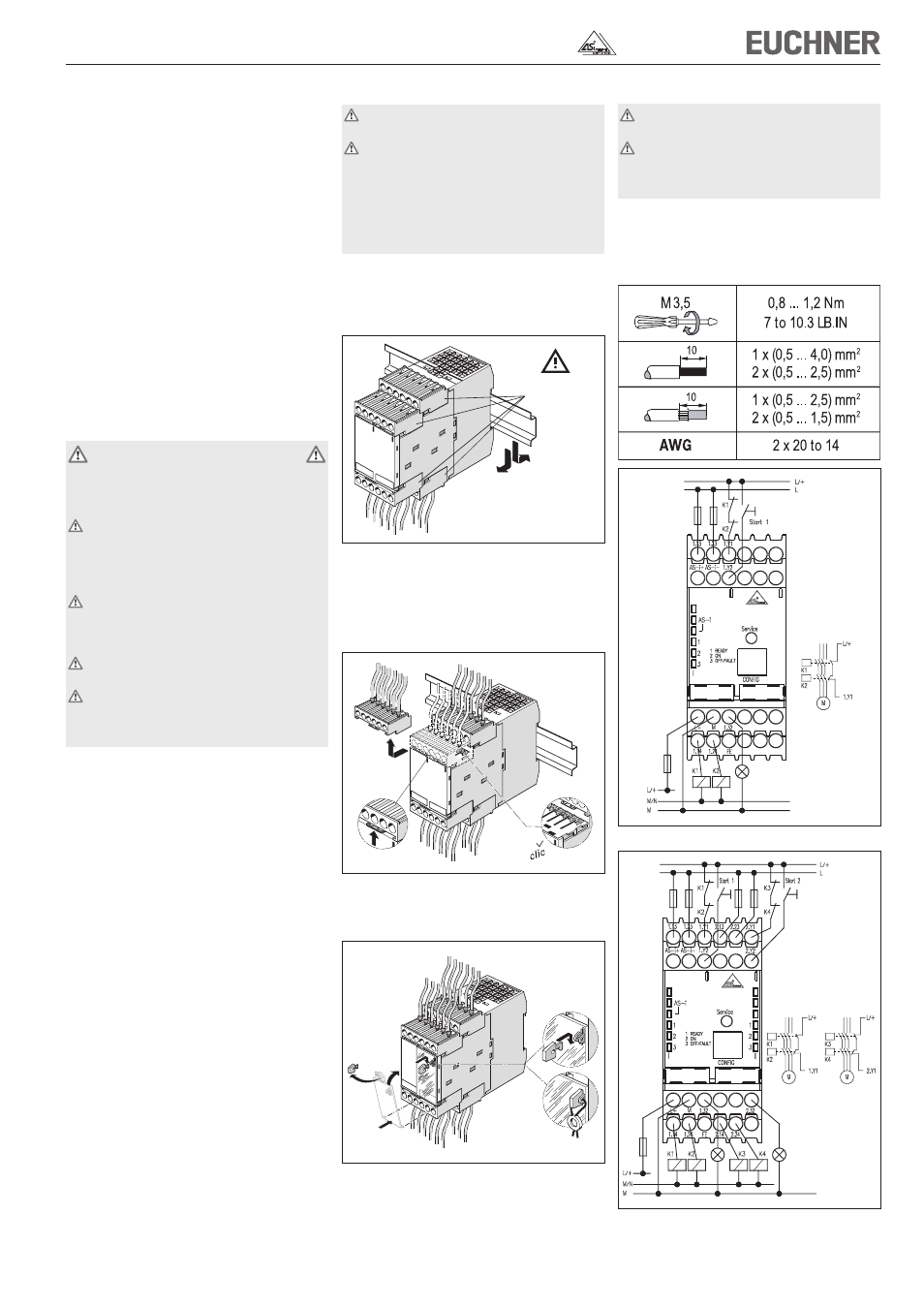

Assembly

Installation must be performed only by authorized

personnel.

It is essential to fit the enclosed cover in order to

protect against electrostatic interference during

operation (see Fig. 3).

The cover must be sealed to prevent tampering.

The safety monitor must be installed in a suit‑

able operating area (switch cabinet, protective

housing ‑ at least IP54).

The safety monitor is mounted by clipping it

onto a standard 35 mm DIN rail according to

DIN EN 60715 TH35 (see Fig. 1).

f

The monitor can be removed by firmly pressing

against the upper rail guide and lifting it out.

Fig. 1: Mounting the safety monitor

f

To remove the coded connection terminals, push

away locking spring a and pull off terminal to the

front (see Figure 2).

f

On fitting, the connection terminal must engage

with a click.

Fig. 2: Removing and fitting coded connection ter‑

minals

f

Fit cap and lock with wire and seal (see Figure 3).

Fig. 3: Fitting and sealing ‑ cover

Refer to the manual of the safety monitor for further

instructions.

Electrical connection

Electrical connection must be performed only

by authorized personnel.

A power supply unit with electrical separation in

accordance with IEC 60742, PELV, must be used

to power the safety monitor and all AS‑Interface

components.

Electrical connection of the safety monitor is realised

by means of screw terminals.

It is essential to adhere to the following tightening

torque values, line cross sections and insulation

stripping lengths:

Fig. 4: Connection safety monitor SFM‑A01/SFM‑B01

Fig. 5: Connection safety monitor SFM‑A02/

SFM‑B02/SFM‑B02A

A

C

D

B

A, B, C, D:

coded

a

A

C

D

B

4

5

4

1

2

3